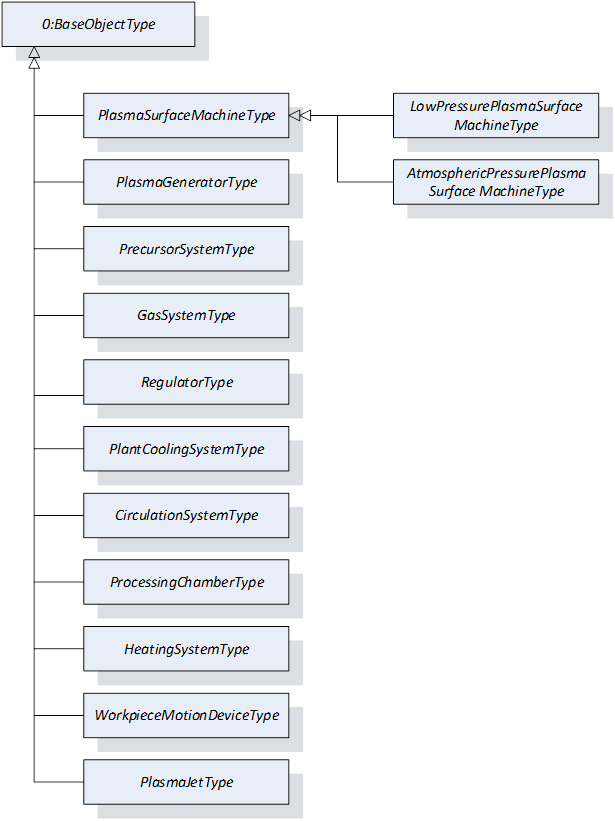

Figure 7 shows all ObjectTypes which are defined by this companion specification.

The parent ObjectType of a general machine for surface treatment using plasma is the PlasmaSurfaceMachineType ObjectType. This ObjectType is divided into the SubTypes LowPressurePlasmaSurfaceMachineType and AtmosphericPressurePlasmaSurfaceMachineType.

This Companion Specification has also defined a separate ObjectType for each system component. These are the ObjectTypes PlasmaGeneratorType, PrecursorSystemType, GasSystemType, PlantCoolingSystemType, ProcessingChamberType, HeatingSystemType, WorkpieceMotionDeviceType and PlasmaJetType.

Figure 7 - ObjectTypes of the OPC for Plasma Surface Machinery

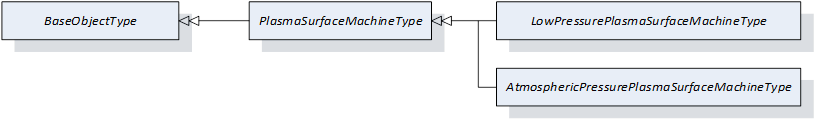

The PlasmaSurfaceMachineType ObjectType defines the representation of a plasma surface treatment machine. The PlasmaSurfaceMachineType represents the SuperType of the LowPressurePlasmaSurfaceMachineType and the AtmosphericPressurePlasmaSurfaceMachineType, as shown in Figure 8.

Figure 8 - Subtypes of the PlasmaSurfaceMachineType

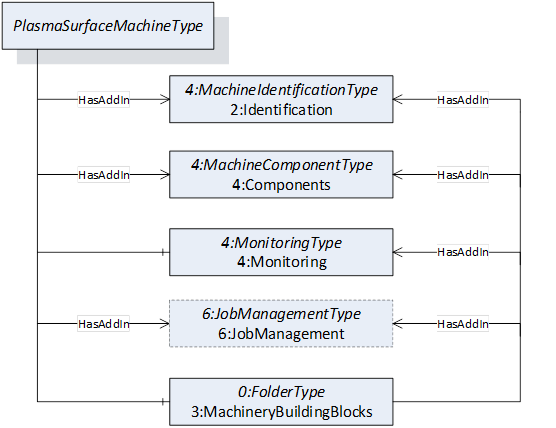

Figure 9 - PlasmaSurfaceMachineType overview

Figure 9 shows the hierarchical structure with some details of this ObjectType. The PlasmaSurfaceMachineType is formally defined in Table 15.

Table 15 – PlasmaSurfaceMachineType Definition

|

Attribute |

Value |

||||

|

BrowseName |

PlasmaSurfaceMachineType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasAddIn |

Object |

2:Identification |

|

4:MachineIdentificationType |

M |

|

0:HasAddIn |

Object |

4:Components |

|

4:MachineComponentsType |

M |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

0:HasAddIn |

Object |

6:JobManagement |

|

6:JobManagementType |

O |

|

0:HasComponent |

Object |

4:MachineryBuildingBlocks |

|

0:FolderType |

M |

|

Conformance Units |

|||||

|

PST PlasmaSurfaceMachineType Basic |

|||||

|

PST PlasmaSurfaceMachineType JobManagement |

|||||

|

PST PlasmaSurfaceMachineType OperationMode |

|||||

|

PST PlasmaSurfaceMachineType Advanced |

|||||

Identification is used as defined in OPC 40001-1 and shall also be referenced as AddIn in the

MachineryBuildingBlocks Folder.

Components is representing a collection of all physical components of the plasma surface treatment machine.

Monitoring is representing a collection of the variables that are not assigned to a component but to the overall plasma surface treatment machine.

MachineryOperationCounter is used as defined in OPC 40001-1. In the information model for plasma surface machines, all counters that are implemented according to the MachineryOperationCounterType of the OPC 40001-1 shall be integrated with the HasComponent reference under this Object. This Object shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

MachineryLifetimeCounter is used as defined in OPC 40001-1. In the information model for plasma surface machines, all counters that are implemented according to the MachineryLifetimeCounterType of the OPC 40001-1 shall be integrated with the HasComponent reference under this Object. This Object shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

JobManagement is used as defined in OPC 40001-3 and shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

MachineryBuildingBlocks is representing a folder that directly references all those building blocks of the OPC UA for Machinery (OPC 40001-1, OPC 40001-3) which are implemented as an add-in in the PlasmaSurfaceMachineType or it’s subtypes.

The components of the PlasmaSurfaceMachineType have additional references which are defined in Table 16.

Table 16 – PlasmaSurfaceMachineType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

2:Identification |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Components |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

6:JobManagement |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Monitoring |

The components of the PlasmaSurfaceMachineType have additional subcomponents which are defined in Table 17.

Table 17 – PlasmaSurfaceMachineType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

4:Components |

0:HasComponent |

Object |

<PlasmaGenerator> |

|

PlasmaGeneratorType |

MP |

||

|

4:Components |

0:HasComponent |

Object |

<PrecursorSystem> |

|

PrecursorSystemType |

OP |

||

|

4:Components |

0:HasComponent |

Object |

<GasSystem> |

|

GasSystemType |

MP |

||

|

4:Components |

0:HasComponent |

Object |

<PlantCoolingSystem> |

|

PlantCoolingSystemType |

OP |

||

|

0:HasProperty |

Variable |

MainSwitchOn |

0:Boolean |

0:PropertyType |

M, RO |

||

|

0:HasComponent |

Variable |

PowerConsumption |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

SubstrateTemperature |

0:Double |

0:AnalogUnitType |

O, RO |

PlasmaGenerator is representing the plasma power supply of the plasma surface treatment machine.

PrecursorSystem is representing the precursor system of the plasma surface treatment machine.

GasSystem is representing the gas supply system of the plasma surface treatment machine.

PlantCoolingSystem is representing the cooling system of the plasma surface treatment machine.

MainSwitchOn is representing the power on status of the plasma surface treatment machine. True means the machine is powered.

PowerConsumption is representing the total power consumption of the plasma surface treatment machine including all its components.

SubstrateTemperature is representing the current temperature of the substrate. The substrate is the workpiece to be plasma treated.

NOTE regarding MachineryOperationMode: The working group for plasma surface treatment machines has agreed that a state transition between the "Maintenance" and "Processing" states does not exist for the plasma surface treatment machines. It is therefore not permitted to execute the TransisionType FromMaintenanceToProcessing and FromProcessingToMaintenance of OPC 40001-1.

The LowPressurePlasmaSurfaceMachineType ObjectType is the representation of a plasma surface treatment machine that performs surface treatment at low pressure. The LowPressurePlasmaSurfaceMachineType is a SubType of the PlasmaSurfaceMachineType. This implies that all nodes of the PlasmaSurfaceMachineType are inherited by the LowPressurePlasmaSurfaceMachineType. The LowPressurePlasmaSurfaceMachineType is formally defined in Table 18.

Table 18 – LowPressurePlasmaSurfaceMachineType Definition

|

Attribute |

Value |

||||

|

BrowseName |

LowPressurePlasmaSurfaceMachineType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the PlasmaSurfaceMachineType |

|||||

|

0:HasAddIn |

Object |

4:Components |

|

4:MachineComponentsType |

M |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

Conformance Units |

|||||

|

PST LowPressurePlasmaSurfaceMachineType Basic |

|||||

|

PST LowPressurePlasmaSurfaceMachineType StateMachine |

|||||

|

PST LowPressurePlasmaSurfaceMachineType HeatingSystem |

|||||

|

PST LowPressurePlasmaSurfaceMachineType WorkpieceMotionDevice |

|||||

|

PST LowPressurePlasmaSurfaceMachineType Advanced |

|||||

The components of the LowPressurePlasmaSurfaceMachineType have additional subcomponents which are defined in Table 19.

Table 19 – LowPressurePlasmaSurfaceMachineType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

4:Components |

0:HasComponent |

Object |

<ProcessingChamber> |

|

ProcessingChamberType |

MP |

||

|

4:Components |

0:HasComponent |

Object |

<HeatingSystem> |

|

HeatingSystemType |

OP |

||

|

4:Components |

0:HasComponent |

Object |

<WorkpieceMotionDevice> |

|

WorkpieceMotionDeviceType |

OP |

||

|

0:HasAddIn |

Object |

4:MachineryItemState |

|

LowPressurePlasmaMachineryItemState_StateMachineType |

O |

ProcessingChamber is representing the processing chamber of the plasma surface treatment machine.

HeatingSystem is representing the heating system of the plasma surface treatment machine.

WorkpieceMotionDevice is representing the device that is moving the workpiece inside of the processing chamber.

NOTE: The LowPressurePlasmaSurfaceMachineType is a subtype of the PlasmaSurfacemachineType. The additional subcomponents mentioned above are referring to the mandatory Components of the PlasmaSurfacemachineType which is inherited to the LowPressurePlasmaSurfacemachineType.

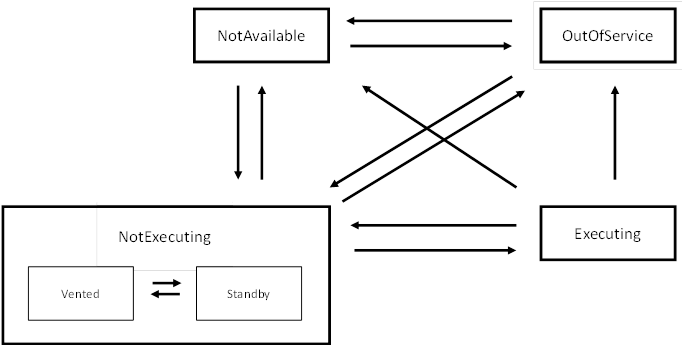

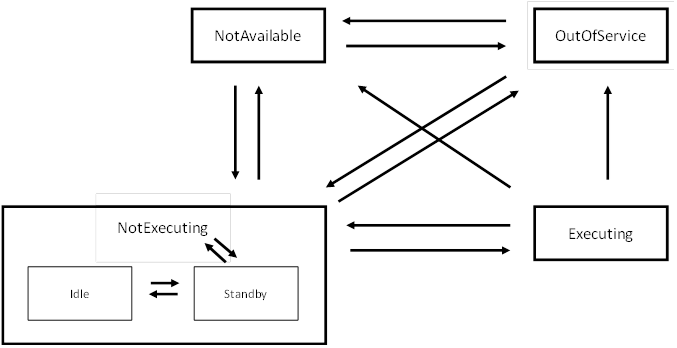

For this specification the MachineryItemState defined in OPC UA for Machinery is extended by a SubStateMachine for the State NotExecuting. An exemplary illustration can be found in Figure 10.

Figure 10 - Extension of MachineryItemState for low pressure plasma surface treatment machines

For this, the LowPressurePlasmaMachineryItemState_StateMachineType is defined in Table 20.

Table 20 – LowPressurePlasmaMachineryItemState_StateMachineType Definition

|

Attribute |

Value |

||||

|

BrowseName |

LowPressurePlasmaMachineryItemState_StateMachineType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of 4:MachineryItemState_StateMachineType defined in OPC UA for Machinery (OPC 40001-1) |

|||||

|

0:HasComponent |

Object |

LowPressurePlasmaNotExecutingSubState |

|

LowPressurePlasmaNotExecutingSubState_StateMachineType |

M |

The State NotExecuting is overriden in the LowPressurePlasmaMachineryItemState_StateMachineType to get the additional reference defined in Table 21.

Table 21 – LowPressurePlasmaMachineryItemState_StateMachineType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

LowPressurePlasmaNotExecutingSubState |

0:HasSubStateMachine |

False |

4:NotExecuting |

The LowPressurePlasmaNotExecutingSubState_StateMachineType is used for a SubStateMachine which divides the NotExecuting State into Vented and Standby. This SubStateMachine is not active if the parent State Executing is not active. In this case the CurrentState and LastTransition Variables of the LowPressurePlasmaNotExecutingSubState state machine shall have a status equal to Bad_StateNotActive.

The LowPressurePlasmaNotExecutingSubState_StateMachineType is formally defined in Table 22.

Table 22 – LowPressurePlasmaNotExecutingSubState_StateMachineType Definition

|

Attribute |

Value |

||||

|

BrowseName |

LowPressurePlasmaNotExecutingSubState_StateMachineType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the 0:FiniteStateMachineType defined in OPC 10000-16, i.e. inheriting the InstanceDeclarations of that Node. |

|||||

|

0:HasProperty |

Variable |

0:DefaultInstanceBrowseName |

0:QualifiedName |

0:PropertyType |

|

|

0:HasComponent |

Object |

Vented |

|

0:StateType |

|

|

0:HasComponent |

Object |

Standby |

|

0:StateType |

|

|

0:HasComponent |

Object |

FromStandbyToVented |

|

0:TransitionType |

|

|

0:HasComponent |

Object |

FromVentedToStandby |

|

0:TransitionType |

|

The InstanceDeclaration of the LowPressurePlasmaNotExecutingSubState_StateMachineType has additional Attributes defined in Table 23.

Table 23 – LowPressurePlasmaNotExecutingSubState_StateMachineType Attribute values for child nodes

|

BrowsePath |

Value Attribute |

Description Attribute |

||

|

0:DefaultInstanceBrowseName |

LowPressurePlasmaNotExecutingSubState |

The default BrowseName for instances of the type |

||

|

Vented |

|

The machine is being prepared for the next run |

||

|

Standby |

|

The vacuum chamber is evacuated and the system is ready to start |

||

|

FromStandbyToVented |

|

Transition from state Standby to state Vented |

||

|

FromVentedToStandby |

|

Transition from state Vented to state Standby |

||

|

0 |

|

||

|

1 |

|

||

|

0 |

|

||

|

1 |

|

The components of the LowPressurePlasmaNotExecutingSubState_StateMachineType have additional references which are defined in Table 24.

Table 24 – LowPressurePlasmaNotExecutingSubState_StateMachineType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

FromStandbyToVented |

0:FromState |

True |

Standby |

|

|

0:ToState |

True |

Vented |

|

FromVentedToStandby |

0:FromState |

True |

Vented |

|

|

0:ToState |

True |

Standby |

The AtmosphericPressurePlasmaSurfaceMachineType ObjectType is the representation of a plasma surface treatment machine that performs surface treatment at atmospheric pressure. The AtmosphericPressurePlasmaSurfaceMachineType is a SubType of the PlasmaSurfaceMachineType. This implies that all nodes of the PlasmaSurfaceMachineType are inherited by the AtmosphericPressurePlasmaSurfaceMachineType. The AtmosphericPressurePlasmaSurfaceMachineType is formally defined in Table 25.

Table 25 – AtmosphericPressurePlasmaSurfaceMachineType Definition

|

Attribute |

Value |

||||

|

BrowseName |

AtmosphericPressurePlasmaSurfaceMachineType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the PlasmaSurfaceMachineType |

|||||

|

0:HasAddIn |

Object |

4:Components |

|

4:MachineComponentsType |

M |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

Conformance Units |

|||||

|

PST AtmosphericPressurePlasmaSurfaceMachineType Basic |

|||||

|

PST AtmosphericPressurePlasmaSurfaceMachineType StateMachine |

|||||

|

PST AtmosphericPressurePlasmaSurfaceMachineType Advanced |

|||||

The components of the AtmosphericPressurePlasmaSurfaceMachineType have additional subcomponents which are defined in Table 26.

Table 26 – AtmosphericPressurePlasmaSurfaceMachineType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

4:Components |

0:HasComponent |

Object |

<PlasmaJet> |

|

PlasmaJetType |

MP |

||

|

0:HasAddIn |

Object |

4:MachineryItemState |

|

AtmosphericPressurePlasmaMachineryItemState_StateMachineType |

O |

PlasmaJet is representing the unit that generates the plasma required for the process.

NOTE: The LowPressurePlasmaSurfaceMachineType is a subtype of the PlasmaSurfacemachineType. The additional subcomponents mentioned above are refering to the mandatory Components of the PlasmaSurfacemachineType which is inherited to the LowPressurePlasmaSurfacemachineType.

For this specification the MachineryItemState defined in OPC UA for Machinery is extended by a SubStateMachine for the State NotExecuting. An exemplary illustration can be found in Figure 11.

Figure 11 - Extension of MachineryItemState for atmospheric pressure plasma surface treatment machines

For this, the AtmosphericPressurePlasmaMachineryItemState_StateMachineType is defined Table 27.

Table 27 – AtmosphericPressurePlasmaMachineryItemState_StateMachineType Definition

|

Attribute |

Value |

||||

|

BrowseName |

AtmosphericPressurePlasmaMachineryItemState_StateMachineType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of 4:MachineryItemState_StateMachineType defined in OPC UA for Machinery (OPC 40001-1) |

|||||

|

0:HasComponent |

Object |

AtmosphericPressurePlasmaNotExecutingSubState |

|

AtmosphericPressurePlasmaNotExecutingSubState_StateMachineType |

M |

The State NotExecuting is overriden in the AtmosphericPressurePlasmaMachineryItemState_StateMachineType to get the additional reference defined in Table 28.

Table 28 – AtmosphericPressurePlasmaMachineryItemState_StateMachineType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

AtmosphericPressurePlasmaNotExecutingSubState |

0:HasSubStateMachine |

False |

4:NotExecuting |

The AtmosphericPressurePlasmaNotExecutingSubState_StateMachineType is used for a SubStateMachine which divides the NotExecuting State into Idle and Standby. This SubStateMachine is not active if the parent State Executing is not active. In this case the CurrentState and LastTransition Variables of the AtmosphericPressurePlasmaNotExecutingSubState state machine shall have a status equal to Bad_StateNotActive.

The AtmosphericPressurePlasmaNotExecutingSubState_StateMachineType is formally defined in Table 29.

Table 29 – AtmosphericPressurePlasmaNotExecutingSubState_StateMachineType Definition

|

Attribute |

Value |

||||

|

BrowseName |

AtmosphericPressurePlasmaNotExecutingSubState_StateMachineType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the 0:FiniteStateMachineType defined in OPC 10000-16, i.e. inheriting the InstanceDeclarations of that Node. |

|||||

|

0:HasProperty |

Variable |

0:DefaultInstanceBrowseName |

QualifiedName |

0:PropertyType |

|

|

0:HasComponent |

Object |

Idle |

|

0:StateType |

|

|

0:HasComponent |

Object |

Standby |

|

0:StateType |

|

|

0:HasComponent |

Object |

FromStandbyToIdle |

|

0:TransitionType |

|

|

0:HasComponent |

Object |

FromIdleToStandby |

|

0:TransitionType |

|

The InstanceDeclaration of the AtmosphericPressurePlasmaNotExecutingSubState_StateMachineType has additional Attributes defined in Table 30.

Table 30 – AtmosphericPressurePlasmaNotExecutingSubState_StateMachineType Attribute values for child nodes

|

BrowsePath |

Value Attribute |

Description Attribute |

||

|

0:DefaultInstanceBrowseName |

AtmosphericPressurePlasmaNotExecutingSubState |

The default BrowseName for instances of the type |

||

|

Idle |

|

The machine is being prepared for the next run |

||

|

Standby |

|

The system is ready to start |

||

|

FromStandbyToIdle |

|

Transition from state Standby to state Idle |

||

|

FromIdleToStandby |

|

Transition from state Idle to state Standby |

||

|

0 |

|

||

|

1 |

|

||

|

0 |

|

||

|

1 |

|

The components of the AtmosphericPressurePlasmaNotExecutingSubState_StateMachineType have additional references which are defined in Table 31.

Table 31 – AtmosphericPressurePlasmaNotExecutingSubState_StateMachineType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

FromStandbyToIdle |

0:FromState |

True |

Standby |

|

|

0:ToState |

True |

Idle |

|

FromIdleToStandby |

0:FromState |

True |

Idle |

|

|

0:ToState |

True |

Standby |

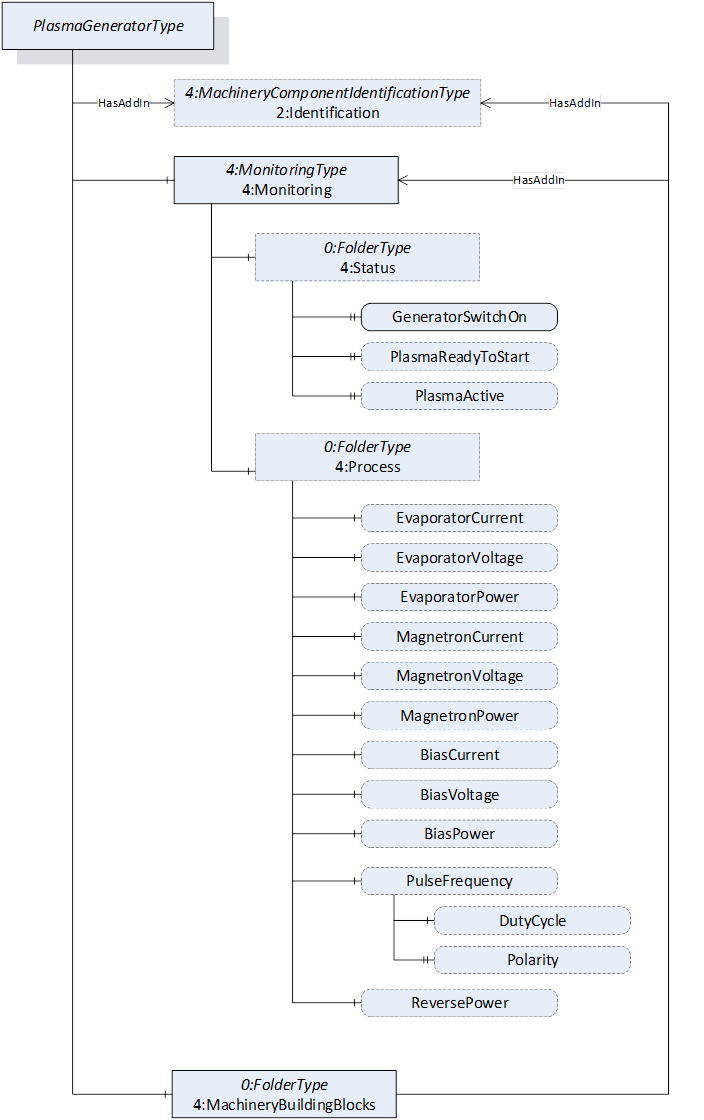

The PlasmaGeneratorType provides all relevant Variables and parameters for monitoring a plasma generator of a plasma surface treatment machine. An overview of the information model is shown in Figure 12.

Figure 12 - PlasmaGeneratorType overview

The PlasmaGeneratorType is formally defined in Table 32.

Table 32 – PlasmaGeneratorType Definition

|

Attribute |

Value |

||||

|

BrowseName |

PlasmaGeneratorType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasAddIn |

Object |

2:Identification |

|

4:MachineryComponentIdentificationType |

O |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

0:HasComponent |

Object |

4:MachineryBuildingBlocks |

|

0:FolderType |

M |

|

Conformance Units |

|||||

|

PST PlasmaGeneratorType Basic |

|||||

|

PST PlasmaGeneratorType Advanced |

|||||

Identification is used as defined in OPC 40001-1 and shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

Monitoring is representing a collection of the variables that are assigned to this specific component.

MachineryBuildingBlocks is representing a folder that directly references all those building blocks of the OPC UA for Machinery (OPC 40001-1, OPC 40001-3) which are implemented as an add-in in this specific component.

The components of the PlasmaGeneratorType have additional references which are defined in Table 33.

Table 33 – PlasmaGeneratorType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

2:Identification |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Monitoring |

The components of the PlasmaGeneratorType have additional subcomponents which are defined in Table 34.

Table 34 – PlasmaGeneratorType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

|||

|

0:HasComponent |

Variable |

EvaporatorCurrent |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

EvaporatorVoltage |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

EvaporatorPower |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

BiasCurrent |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

BiasVoltage |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

BiasPower |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasProperty |

Variable |

BiasGeneratorSwitchOn |

0:Boolean |

0:PropertyType |

O, RO |

|||

|

0:HasComponent |

Variable |

BiasArcCounter |

UInt32 |

0:AnalogUnitType |

O, RO |

|||

|

0:HasProperty |

Variable |

EvaporatorGeneratorSwitchOn |

0:Boolean |

0:PropertyType |

O, RO |

|||

|

0:HasProperty |

Variable |

PlasmaReadyToStart |

0:Boolean |

0:PropertyType |

O, RO |

|||

|

0:HasProperty |

Variable |

PlasmaActive |

0:Boolean |

0:PropertyType |

O, RO |

|||

|

0:HasComponent |

Variable |

BiasPulseFrequency |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

BiasDutyCycle |

UInt16 |

0:AnalogUnitType |

O, RO |

|||

|

0:HasProperty |

Variable |

BiasPolarity |

0:String |

0:PropertyType |

O, RO |

|||

|

0:HasComponent |

Variable |

EvaporatorPulseFrequency |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

EvaporatorDutyCycle |

UInt16 |

0:AnalogUnitType |

O, RO |

|||

|

0:HasProperty |

Variable |

EvaporatorPolarity |

0:String |

0:PropertyType |

O, RO |

|||

|

0:HasComponent |

Variable |

BiasReversePower |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

EvaporatorReversePower |

0:Double |

0:AnalogUnitType |

O, RO |

EvaporatorCurrent is representing the present current of the evaporator.

EvaporatorVoltage is representing the present voltage of the evaporator.

EvaporatorPower is representing the present power of the evaporator.

BiasCurrent is representing the present current of the bias.

BiasVoltage is representing the present voltage of the bias.

BiasPower is representing the present power of the bias.

BiasGeneratorSwitchOn is indicating the power on status of the bias generator. True means the generator is switched on.

BiasArcCounter is counting the amount of arc events during the process.

EvaporatorGeneratorSwitchOn is indicating the power on status of the evaporator generator. True means the generator is switched on.

PlasmaReadyToStart is indicating if the plasma can be switched on. True means the plasma can be switched on.

PlasmaActive is indicating if the plasma is working.

BiasPulseFrequency is representing the output frequency of the bias generator.

BiasDutyCycle is a descriptive property of BiasPulseFrequency. It is representing the pulse ontime in percent.

BiasPolarity is a descriptive property of BiasPulseFrequency. It is indicating what polarity the BiasPulseFrequence has.

EvaporatorPulseFrequency is representing the output frequency of the evaporator generator.

EvaporatorDutyCycle is a descriptive property of EvaporatorPulseFrequency. It is representing the pulse ontime in percent.

EvaporatorPolarity is a descriptive property of EvaporatorPulseFrequency. It is indicating what polarity the EvaporatorPulseFrequence has.

BiasReversePower is representing the power which flows back into the generator. It is also known by the name “reflected power”.

EvaporatorReversePower is representing the power which flows back into the generator. It is also known by the name “reflected power”.

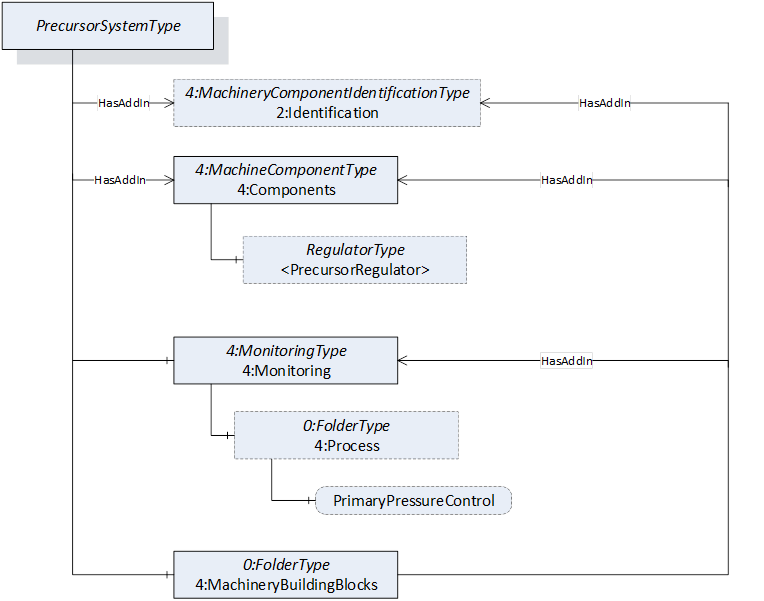

The PrecursorSystemType provides all relevant Variables and parameters for monitoring a precursor system of a plasma surface treatment machine. An overview of the information model is shown in Figure 13.

Figure 13 - PrecursorSystemType overview

The PrecursorSystemType is formally defined in Table 35.

Table 35 – PrecursorSystemType Definition

|

Attribute |

Value |

||||

|

BrowseName |

PrecursorSystemType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasAddIn |

Object |

2:Identification |

|

4:MachineryComponentIdentificationType |

O |

|

0:HasAddIn |

Object |

4:Components |

|

4:MachineComponentsType |

M |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

0:HasComponent |

Object |

4:MachineryBuildingBlocks |

|

0:FolderType |

M |

|

Conformance Units |

|||||

|

PST PrecursorSystemType Basic |

|||||

|

PST PrecursorSystemType Advanced |

|||||

Identification is used as defined in OPC 40001-1 and shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

Components is representing a collection of all physical components of the precursor system of a plasma surface treatment machine.

Monitoring is representing a collection of the variables that are assigned to this specific component.

MachineryBuildingBlocks is representing a folder that directly references all those building blocks of the OPC UA for Machinery (OPC 40001-1, OPC 40001-3) which are implemented as an add-in in this specific component.

The components of the PrecursorSystemType have additional references which are defined in Table 36.

Table 36 – PrecursorSystemType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

2:Identification |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Components |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Monitoring |

The components of the PrecursorSystemType have additional subcomponents which are defined in Table 37.

Table 37 – PrecursorSystemType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

0:HasComponent |

Variable |

PrimaryPressureControl |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

4:Components |

0:HasComponent |

Object |

<PrecursorRegulator> |

|

RegulatorType |

OP |

PrimaryPressureControl is representing the prepressure of the precursor system.

PrecursorRegulator is representing an instance of a single precursor regulator of the gas system.

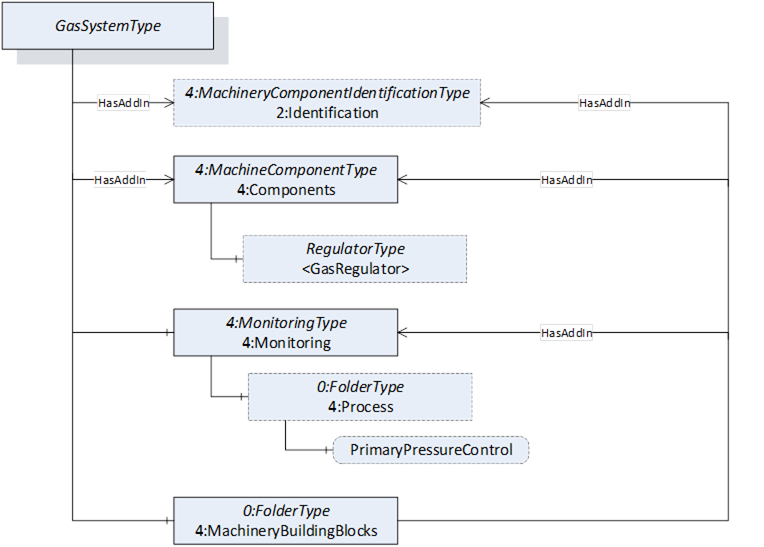

The GasSystemType provides all relevant Variables and parameters for monitoring a gas supply system of a plasma surface treatment machine. An overview of the information model is shown in Figure 14.

Figure 14 - GasSystemType overview

The GasSystemType is formally defined in Table 38.

Table 38 – GasSystemType Definition

|

Attribute |

Value |

||||

|

BrowseName |

GasSystemType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasAddIn |

Object |

2:Identification |

|

4:MachineryComponentIdentificationType |

O |

|

0:HasAddIn |

Object |

4:Components |

|

4:MachineComponentsType |

M |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

0:HasComponent |

Object |

4:MachineryBuildingBlocks |

|

0:FolderType |

M |

|

Conformance Units |

|||||

|

PST GasSystemType Basic |

|||||

|

PST GasSystemType Advanced |

|||||

Identification is used as defined in OPC 40001-1. Shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

Components is representing a collection of all physical components of the gas system of a plasma surface treatment machine.

Monitoring is representing a collection of the variables that are assigned to this specific component.

MachineryBuildingBlocks is representing a folder that directly references all those building blocks of the OPC UA for Machinery (OPC 40001-1, OPC 40001-3) which are implemented as an add-in in this specific component.

The components of the GasSystemType have additional references which are defined in Table 39.

Table 39 – GasSystemType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

2:Identification |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Components |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Monitoring |

The components of the GasSystemType have additional subcomponents which are defined in Table 40.

Table 40 – GasSystemType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

0:HasComponent |

Variable |

PrimaryPressureControl |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

4:Components |

0:HasComponent |

Object |

<GasRegulator> |

|

RegulatorType |

OP |

PrimaryPressureControl is representing the prepressure of the gas system.

GasRegulator is representing an instance of a single gas regulator of the gas system.

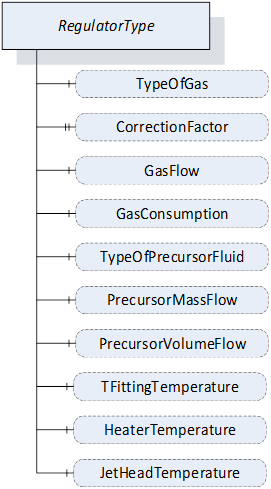

The RegulatorType provides a representation of a single gas or precursor regulator that is controlling the gas or precursor flow. An overview of the information model is shown in Figure 15.

Figure 15 - RegulatorType overview

The RegulatorType is formally defined in Table 41.

Table 41 – RegulatorType Definition

|

Attribute |

Value |

||||

|

BrowseName |

RegulatorType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasComponent |

Variable |

TypeOfGas |

0:UInt16 |

0:MultiStateValueDiscreteType |

O, RW |

|

0:HasProperty |

Variable |

CorrectionFactor |

0:Double |

0:PropertyType |

O, RW |

|

0:HasComponent |

Variable |

GasFlow |

0:Double |

0:AnalogUnitType |

O, RO |

|

0:HasComponent |

Variable |

GasConsumption |

0:Double |

0:AnalogUnitType |

O, RO |

|

0:HasComponent |

Variable |

TypeOfPrecursorFluid |

0:UInt16 |

0:MultiStateValueDiscreteType |

O, RW |

|

0:HasComponent |

Variable |

PrecursorMassFlow |

0:Double |

0:AnalogUnitType |

O, RO |

|

0:HasComponent |

Variable |

PrecursorVolumeFlow |

0:Double |

0:AnalogUnitType |

O, RO |

|

0:HasComponent |

Variable |

TFittingTemperature |

0:Double |

0:AnalogUnitType |

O, RO |

|

0:HasComponent |

Variable |

HeaterTemperature |

0:Double |

0:AnalogUnitType |

O, RO |

|

0:HasComponent |

Variable |

JetHeadTemperature |

0:Double |

0:AnalogUnitType |

O, RO |

GasType is representing the type of gas used.

CorrectionFactor is representing the correction factor of the used gas. As the gas regulator is calibrated to a specific gas, correction factors are required when using other gases. The CorrectionFactor is representing this factor for the gas used.

GasFlow is representing the flow of the gas through the gas system.

GasConsumption is representing the total gas consumption of the gas regulator.

TypeOfPrecursorFluid is indicating which type of precursor gas is used in the precursor system.

PrecursorMassFlow is representing the mass flow of the precursant gas through the precursor system.

PrecursorVolumeFlow is representing the volume flow of the precursant gas through the precursor system.

TFittingTemperature is representing the current temperature at the T-Fitting of the precursor system.

HeaterTemperature is representing the current temperature of the heater of the precursor system.

JetHeadTemperature is representing the current temperature of the jet head of the precursor system.

The component Variables of the RegulatorType have additional Attributes defined in Table 42.

Table 42 – RegulatorType Attribute values for child nodes

|

BrowsePath |

Value Attribute |

Description Attribute |

||

|

[ {"Value": 0, "DisplayName": "Ar", "Description": ""}, {"Value": 1, "DisplayName": "N2", "Description": ""}, {"Value": 2, "DisplayName": "CH4", "Description": ""}, {"Value": 3, "DisplayName": "C2H2", "Description": ""}, {"Value": 4, "DisplayName": "O2", "Description": ""}, {"Value": 5, "DisplayName": "H2", "Description": ""}, ] |

|

||

|

[ {"Value": 0, "DisplayName": "Ar", "Description": ""}, {"Value": 1, "DisplayName": "N2", "Description": ""}, {"Value": 2, "DisplayName": "CH4", "Description": ""}, {"Value": 3, "DisplayName": "C2H2", "Description": ""}, {"Value": 4, "DisplayName": "O2", "Description": ""}, {"Value": 5, "DisplayName": "H2", "Description": ""}, ] |

|

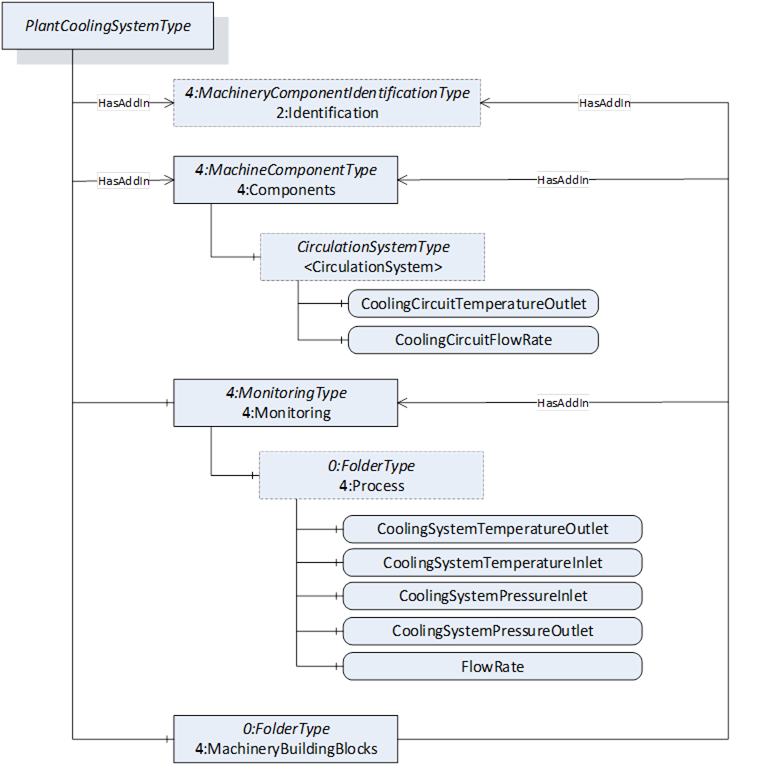

The PlantCoolingSystemType provides all relevant Variables and parameters for monitoring a cooling system of a plasma surface treatment machine. An overview of the information model is shown in Figure 16.

Figure 16 - PlantCoolingSystemType overview

The PlantCoolingSystemType is formally defined in Table 43.

Table 43 – PlantCoolingSystemType Definition

|

Attribute |

Value |

||||

|

BrowseName |

PlantCoolingSystemType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasAddIn |

Object |

2:Identification |

|

4:MachineryComponentIdentificationType |

O |

|

0:HasAddIn |

Object |

4:Components |

|

4:MachineComponentsType |

M |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

0:HasComponent |

Object |

4:MachineryBuildingBlocks |

|

0:FolderType |

M |

|

Conformance Units |

|||||

|

PST PlantCoolingSystemType Basic |

|||||

|

PST PlantCoolingSystemType Advanced |

|||||

Identification is used as defined in OPC 40001-1. Shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

Components is representing a collection of all physical components of the plasma surface treatment machine.

Monitoring is representing a collection of the variables that are assigned to this specific component.

MachineryBuildingBlocks is representing a folder that directly references all those building blocks of the OPC UA for Machinery (OPC 40001-1, OPC 40001-3) which are implemented as an add-in in this specific component.

The components of the PlantCoolingSystemType have additional references which are defined in Table 44.

Table 44 – PlantCoolingSystemType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

2:Identification |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Components |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Monitoring |

The components of the PlantCoolingSystemType have additional subcomponents which are defined in Table 45.

Table 45 – PlantCoolingSystemType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

4:Components |

0:HasComponent |

Object |

<CirculationSystem> |

|

CirculationSystemType |

OP |

||

|

0:HasComponent |

Variable |

FlowRate |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

CoolingSystemTemperatureOutlet |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

CoolingSystemTemperatureInlet |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

CoolingSystemPressureInlet |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

CoolingSystemPressureOutlet |

0:Double |

0:AnalogUnitType |

O, RO |

CirculationSystem is representing a single cooling circuit of the whole cooling system.

FlowRate is representing the volume flow of coolant through the whole plant cooling system.

CoolingSystemTemperatureOutlet is representing the temperature of the coolant at the outlet of the main coolant storage.

CoolingSystemTemperatureInlet is representing the temperature of the coolant at the inlet of the main coolant storage.

CoolingSystemPressureInlet is representing the pressure of the inlet of the main coolant storage.

CoolingSystemPressureOutlet is representing the pressure of the outlet of the main coolant storage.

The CirculationSystemType provides a representation of a single circuit of the cooling system of a plasma surface treatment machine. An Instance of the PlantCoolingSystemType can have several Instances of the CirculationSystemsType as components. The CirculationSystemType is formally defined in Table 46.

Table 46 – CirculationSystemType Definition

|

Attribute |

Value |

||||

|

BrowseName |

CirculationSystemType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasComponent |

Variable |

CoolingCircuitTemperatureOutlet |

0:Double |

0:AnalogUnitType |

O, RO |

|

0:HasComponent |

Variable |

CoolingCircuitFlowRate |

0:Double |

0:AnalogUnitType |

O, RO |

CoolingCircuitTemperatureOutlet is representing the temperature of the coolant at the outlet of the specific cooling circuit.

CoolingCircuitFlowRate is representing the volume flow of coolant through the specific cooling circuit.

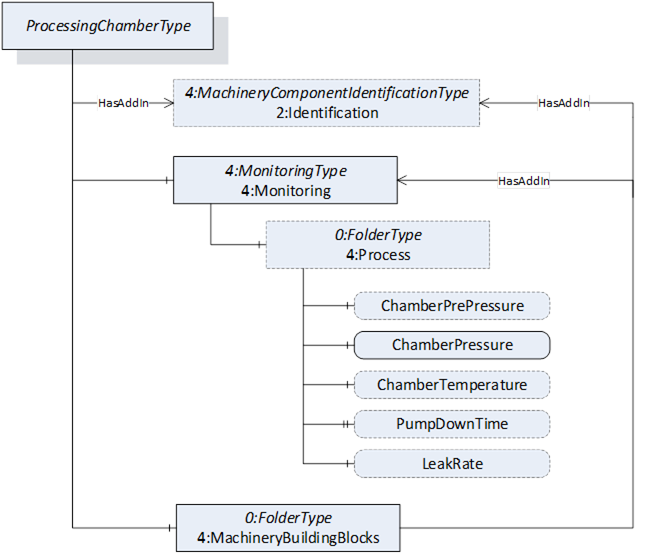

The ProcessingChamberType provides all relevant Variables and parameters for monitoring a processing chamber of a low pressure plasma surface treatment machine. An overview of the information model is shown in Figure 17.

Figure 17 - ProcessingChamberType overview

The ProcessingChamberType is formally defined in Table 47.

Table 47 – ProcessingChamberType Definition

|

Attribute |

Value |

||||

|

BrowseName |

ProcessingChamberType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasAddIn |

Object |

2:Identification |

|

4:MachineryComponentIdentificationType |

O |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

0:HasComponent |

Object |

4:MachineryBuildingBlocks |

|

0:FolderType |

M |

|

Conformance Units |

|||||

|

PST ProcessingChamberType Basic |

|||||

|

PST ProcessingChamberType Advanced |

|||||

Identification is used as defined in OPC 40001-1. Shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

Monitoring is representing a collection of the variables that are assigned to this specific component.

MachineryOperationCounter is used as defined in OPC 40001-1. In the component ProcessingChamberType all counters that are implemented according to the MachineryOperationCounterType of the OPC 40001-1 shall be integrated with the HasComponent reference under this Object. This Object shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

MachineryBuildingBlocks is representing a folder that directly references all those building blocks of the OPC UA for Machinery (OPC 40001-1, OPC 40001-3) which are implemented as an add-in in this specific component.

The components of the ProcessingChamberType have additional references which are defined in Table 48.

Table 48 – ProcessingChamberType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

2:Identification |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Monitoring |

The components of the ProcessingChamberType have additional subcomponents which are defined in Table 49.

Table 49 – ProcessingChamberType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

0:HasComponent |

Variable |

ChamberPrePressure |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

ChamberPressure |

0:Double |

0:AnalogUnitType |

M, RO |

||

|

0:HasComponent |

Variable |

ChamberTemperature |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasProperty |

Variable |

PumpDownTime |

0:DurationString |

0:PropertyType |

O, RO |

||

|

0:HasComponent |

Variable |

LeakRate |

0:Double |

0:AnalogUnitType |

O, RO |

ChamberPrePressure is representing the current pre-pressure of the processing chamber.

ChamberPressure is representing the current pressure inside the processing chamber.

ChamberTemperature is representing the current temperature inside the processing chamber.

PumpDownTime is representing the time needed for evacuating the processing chamber. When the evacuation of the processing chamber has not yet been completed, the PumpDownTime is the time required so far. When the target pressure of the processing chamber has been reached, the PumpDownTime represents the total duration of the evacuation.

LeakRate is representing in what period of time the processing chamber loses what pressure.

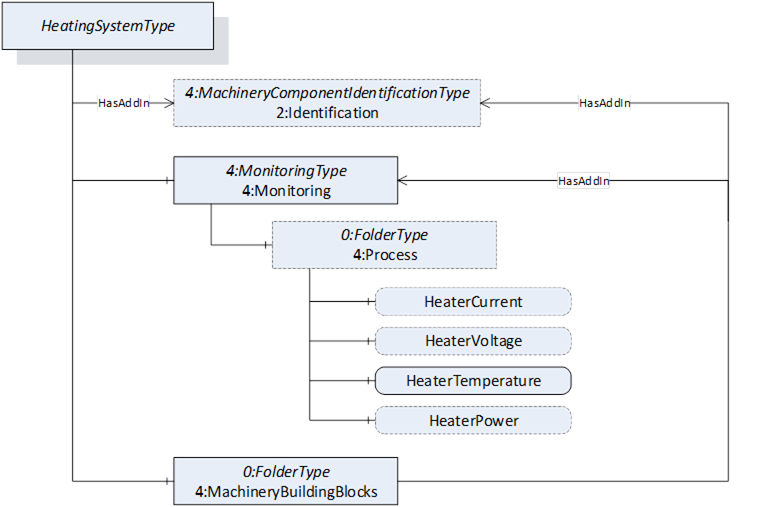

The HeatingSystemType provides all relevant Variables and parameters for monitoring a heating system of a plasma surface treatment machine. An overview of the information model is shown in Figure 18.

Figure 18 - HeatingSystemType overview

The HeatingSystemType is formally defined in Table 50.

Table 50 – HeatingSystemType Definition

|

Attribute |

Value |

||||

|

BrowseName |

HeatingSystemType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasAddIn |

Object |

2:Identification |

|

4:MachineryComponentIdentificationType |

O |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

0:HasComponent |

Object |

4:MachineryBuildingBlocks |

|

0:FolderType |

M |

|

Conformance Units |

|||||

|

PST HeatingSystemType Basic |

|||||

|

PST HeatingSystemType Advanced |

|||||

Identification is used as defined in OPC 40001-1. Shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

Monitoring is representing a collection of the variables that are assigned to this specific component.

MachineryBuildingBlocks is representing a folder that directly references all those building blocks of the OPC UA for Machinery (OPC 40001-1, OPC 40001-3) which are implemented as an add-in in this specific component.

The components of the HeatingSystemType have additional references which are defined in Table 51.

Table 51 – HeatingSystemType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

2:Identification |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Monitoring |

The components of the HeatingSystemType have additional subcomponents which are defined in Table 52.

Table 52 – HeatingSystemType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

0:HasComponent |

Variable |

HeaterCurrent |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

HeaterVoltage |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

HeaterTemperature |

0:Double |

0:AnalogUnitType |

M, RO |

||

|

0:HasComponent |

Variable |

HeaterPower |

0:Double |

0:AnalogUnitType |

O, RO |

HeaterCurrent is representing the present current of the heater.

HeaterVoltage is representing the present voltage of the heater.

HeaterTemperature is representing the present temperature of the heater.

HeaterPower is representing the present power of the heater.

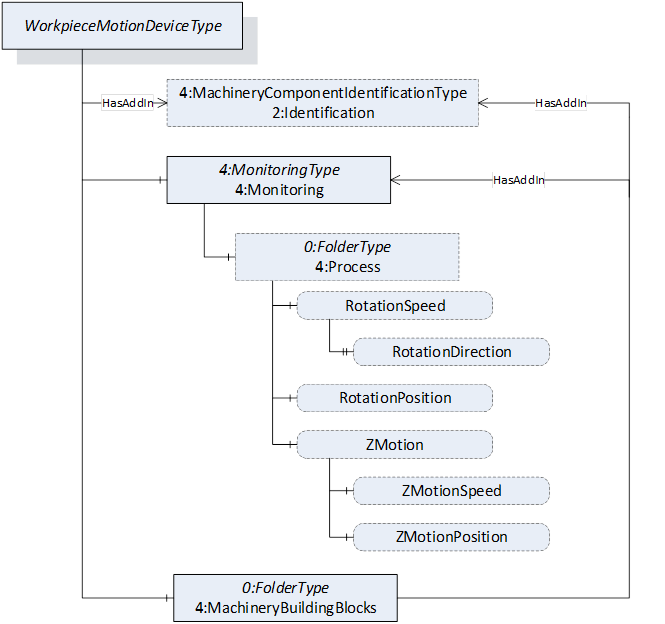

The WorkpieceMotionDeviceType provides all relevant Variables and parameters for monitoring a device that moves the treated workpiece of a plasma surface treatment machine. An overview of the information model is shown in Figure 19.

Figure 19 - WorkpieceMotionDevice overview

The WorkpieceMotionDevice is formally defined in Table 53.

Table 53 – WorkpieceMotionDeviceType Definition

|

Attribute |

Value |

||||

|

BrowseName |

WorkpieceMotionDeviceType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasAddIn |

Object |

2:Identification |

|

4:MachineryComponentIdentificationType |

O |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

0:HasComponent |

Object |

4:MachineryBuildingBlocks |

|

0:FolderType |

M |

|

Conformance Units |

|||||

|

PST WorkpieceMotionDeviceType Basic |

|||||

|

PST WorkpieceMotionDeviceType Advanced |

|||||

Identification is used as defined in OPC 40001-1. Shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

Monitoring is representing a collection of the variables that are assigned to this specific component.

MachineryBuildingBlocks is representing a folder that directly references all those building blocks of the OPC UA for Machinery (OPC 40001-1, OPC 40001-3) which are implemented as an add-in in this specific component.

The components of the WorkpieceMotionDevice have additional references which are defined in Table 54.

Table 54 – WorkpieceMotionDeviceType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

2:Identification |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Monitoring |

The components of the WorkpieceMotionDeviceType have additional subcomponents which are defined in Table 55.

Table 55 – WorkpieceMotionDeviceType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

|||

|

0:HasComponent |

Variable |

RotationSpeed |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasProperty |

Variable |

RotationDirection |

0:Boolean |

0:PropertyType |

O, RO |

|||

|

0:HasComponent |

Variable |

RotationPosition |

0:Int16 |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

ZMotion |

0:Boolean |

0:BaseDataVariableType |

O, RO |

|||

|

0:HasComponent |

Variable |

ZMotionSpeed |

0:Double |

0:AnalogUnitType |

O, RO |

|||

|

0:HasComponent |

Variable |

ZMotionPosition |

0:Int16 |

0:AnalogUnitType |

O, RO |

RotationSpeed is representing the current rotational speed of the workpiece motion device.

RotationDirection is a descriptive property of RotationSpeed that is representing the current direction of the rotation of the workpiece motion device. True value corresponds to clockwise rotation.

RotationPosition is representing the current rotational position of the workpiece motion device.

ZMotion is representing the information if the motion device is active in the vertical direction. The value true means the motion device is active in the vertical direction.

ZMotionSpeed is a descriptive property of ZMotion that is representing the current speed of the motion perpendicular to rotation plane of the workpiece motion device.

ZMotionPosition is a descriptive property of ZMotion that is representing the current position perpendicular to rotation plane of the workpiece motion device.

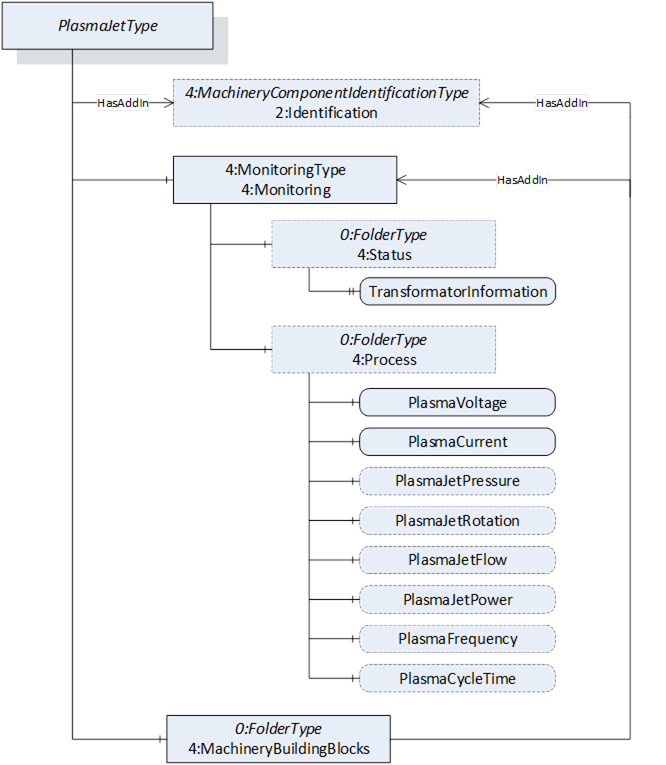

The PlasmaJetType provides all relevant Variables and parameters for monitoring a plasma jet of a plasma surface treatment machine. An overview of the information model is shown in Figure 20.

Figure 20 - PlasmaJetType overview

The PlasmaJetType is formally defined in Table 56.

Table 56 – PlasmaJetType Definition

|

Attribute |

Value |

||||

|

BrowseName |

PlasmaJetType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseObjectType defined in OPC 10000-5 |

|||||

|

0:HasAddIn |

Object |

2:Identification |

|

4:MachineryComponentIdentificationType |

O |

|

0:HasComponent |

Object |

4:Monitoring |

|

4:MonitoringType |

M |

|

0:HasComponent |

Object |

4:MachineryBuildingBlocks |

|

0:FolderType |

M |

|

Conformance Units |

|||||

|

PST PlasmaJetType Basic |

|||||

|

PST PlasmaJetType Identification |

|||||

|

PST PlasmaJetType Advanced |

|||||

Identification is used as defined in OPC 40001-1. Shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

Monitoring is representing a collection of the variables that are assigned to this specific component.

MachineryOperationCounter is used as defined in OPC 40001-1. In the component PlasmaJetType all counters that are implemented according to the MachineryOperationCounterType of the OPC 40001-1 shall be integrated with the HasComponent reference under this Object. This Object shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

MachineryLifetimeCounter is used as defined in OPC 40001-1. In the component PlasmaJetType all counters that are implemented according to the MachineryLifetimeCounterType of the OPC 40001-1 shall be integrated with the HasComponent reference under this Object. This Object shall also be referenced as AddIn in the MachineryBuildingBlocks Folder.

MachineryBuildingBlocks is representing a folder that directly references all those building blocks of the OPC UA for Machinery (OPC 40001-1, OPC 40001-3) which are implemented as an add-in in this specific component.

The components of the PlasmaJetType have additional references which are defined in Table 57.

Table 57 – PlasmaJetType Additional References

|

SourceBrowsePath |

Reference Type |

Is Forward |

TargetBrowsePath |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

2:Identification |

|

4:MachineryBuildingBlocks |

0:HasAddIn |

True |

4:Monitoring |

The components of the PlasmaJetType have additional subcomponents which are defined in Table 58.

Table 58 – PlasmaJetType Additional Subcomponents

|

Source Path |

Reference |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

0:HasComponent |

Variable |

PlasmaVoltage |

0:Double |

0:AnalogUnitType |

M, RO |

||

|

0:HasComponent |

Variable |

PlasmaCurrent |

0:Double |

0:AnalogUnitType |

M, RO |

||

|

0:HasComponent |

Variable |

PlasmaJetPressure |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

PlasmaJetRotation |

0:Int32 |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

PlasmaJetFlow |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

PlasmaJetPower |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

PlasmaFrequency |

0:Double |

0:AnalogUnitType |

O, RO |

||

|

0:HasComponent |

Variable |

PlasmaCycleTime |

0:UInt16 |

0:AnalogUnitType |

O, RO |

||

|

0:HasProperty |

Variable |

TransformatorInformation |

0:String |

0:PropertyType |

M, RO |

PlasmaVoltage is representing the present voltage of the plasma generator.

PlasmaCurrent is representing the present current of the plasma generator.

PlasmaJetPressure is representing the present jet pressure of the plasma jet.

PlasmaJetRotation is representing the present rotational speed of the plasma jet.

PlasmaJetFlow is representing the present ionization gas flow of the plasma jet.

PlasmaJetPower is representing the present power of the plasma jet.

PlasmaFrequency is representing the present plasma frequency of the plasma generator.

PlasmaCycleTime is representing the present plasma cycle time of the plasma generator.

TransformatorInformation is representing important information of the transformer of the plasma jet. This Variable should carry all information necessary to replace the transformer.