This ObjectType contains components which are necessary to operate the LDS. It is formally defined in Table 2.

Table 2 – OperationType Definition

|

Attribute |

Value |

||||

|

BrowseName |

OperationType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of 0:BaseObjectType defined in OPC UA Part 5 |

|||||

|

0:HasProperty |

Variable |

DeviceMappingNumber |

0:UInt32 |

0:PropertyType |

M, RW |

|

0:HasComponent |

Method |

IdentifyDevice |

|

|

O |

|

0:HasProperty |

Variable |

HighestActiveAlarmSeverity |

0:UInt16 |

0:PropertyType |

M, RO |

|

0:HasComponent |

Variable |

ActiveErrors |

3:ClassifiedActiveErrorDataType[] |

0:BaseDataVariableType |

M, RO |

|

0:HasComponent |

Method |

ResetAllErrors |

|

|

O |

|

0:HasComponent |

Method |

ResetErrorById |

|

|

O |

|

0:HasComponent |

Method |

SetCycleNumber |

|

|

O |

|

0:HasProperty |

Variable |

MaterialBalanceSystemType |

MaterialBalanceSystemTypeEnumeration |

0:PropertyType |

M, RO |

|

0:HasProperty |

Variable |

ActivateMaterialBalanceSystem |

0:Boolean |

0:PropertyType |

O, RW |

|

0:HasComponent |

Variable |

DeliveryType |

0:UInt16 |

0:MultiStateValueDiscreteType |

M, RW |

|

0:HasComponent |

Object |

DeliveryPressure |

|

3:ControlledParameterType |

O |

|

0:HasComponent |

Variable |

DeliveryPressureMeasuringPoint |

0:UInt16 |

0:MultiStateValueDiscreteType |

O, RW |

|

0:HasComponent |

Object |

DeliveryFlowrate |

|

3:ControlledParameterType |

O |

|

0:HasComponent |

Variable |

ActualShotWeight |

0:Double |

0:AnalogItemType |

O, RO |

|

0:HasComponent |

Variable |

SetShotWeight |

0:Double |

0:AnalogItemType |

O, RW |

|

0:HasComponent |

Variable |

SetValueCompositeDensity |

0:Double |

0:AnalogItemType |

O, RW |

|

0:HasComponent |

Variable |

MixingRatioTarget |

0:Double |

0:AnalogItemType |

O, RW |

|

0:HasComponent |

Variable |

MaxDeviationMixingRatio |

0:Double |

0:AnalogItemType |

O, RW |

|

0:HasComponent |

Variable |

TargetDeviationMixingRatio |

0:Double |

0:AnalogItemType |

O, RO |

|

0:HasComponent |

Variable |

ActualDeviationMixingRatio |

0:Double |

0:AnalogItemType |

O, RO |

|

0:HasComponent |

Variable |

RemainingMaterialTime |

0:Duration |

0:BaseDataVariableType |

O, RO |

|

0:HasComponent |

Variable |

PurgeMode |

0:UInt16 |

0:MultiStateValueDiscreteType |

O, RW |

|

0:HasProperty |

Variable |

PurgeStatus |

PurgeStatusEnumeration |

0:PropertyType |

O, RO |

|

0:HasComponent |

Variable |

ActivateRemoteControl |

0:UInt16 |

0:MultiStateValueDiscreteType |

M, RW |

|

0:HasComponent |

Variable |

RemoteControlActivated |

0:UInt16 |

0:MultiStateValueDiscreteType |

M, RO |

|

0:HasComponent |

Method |

StartDosing |

|

|

O |

|

0:HasComponent |

Method |

StopDosing |

|

|

O |

|

0:HasComponent |

Object |

Component_A |

|

ComponentType |

M |

|

0:HasComponent |

Object |

Component_B |

|

ComponentType |

M |

|

0:HasComponent |

Object |

Additive_<Y> |

|

AdditiveType |

OP |

|

0:GeneratesEvent |

ObjectType |

LDSCycleParametersEventType |

Defined in 9.24 |

||

The BrowseName of ComponentType shal be built of “Component_” and a character ‘A’, ‘B’ , … (e.g. Component_A, Component_B).

The BrowseName of AdditiveType shall be built of “Additive_” and a number from 1 to n. (e.g. Additive_1).

Description:Unique identifier/address/number for devices of the same DeviceType within a local network. Several peripheral devices of the same DeviceType can be connected to an IMM. In most applications, the IMM must map the connected peripheral devices to internal logical devices and zones in a fixed configuration (e.g. hot runner systems according to the wiring or temperature control devices according to the tubing).

The mapping shall be stable after reconnecting the devices and is therefore not possible via IP addresses, which can be assigned dynamically via DHCP. DeviceMappingNumber sets the mapping order of peripheral devices of the same type on the local network and is therefore of type UInt32.

Example:1

Description:The peripheral device on which this method is called shows itself by e.g. activation of a LED.

Signature:

IdentifyDevice ();

The method has no Input- or OutputArguments.

Table 3 – IdentifyDevice Method AddressSpace Definition

|

Attribute |

Value |

||||

|

BrowseName |

IdentifyDevice |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Modelling Rule |

Description:Indication of the severity of the highest active alarm (0 = no active alarm – 1000 = possible error). It provides a minimal error handling for devices without alarm support. However, the variable shall be filled even if alarms are supported.

Example:400

Description:List of the active errors of the device. It provides a minimal error handling for devices without alarm support. However, the variable shall be filled even if alarms are supported. The ClassifiedActiveErrorDataType is defined in OPC 40083. If there is no active error, the array is empty.

Description:Method to reset all errors of the device.

Signature:

ResetAllErrors();

The method has no Input- or OutputArguments.

Table 4 – ResetAllErrors Method AddressSpace Definition

|

Attribute |

Value |

||||

|

BrowseName |

ResetAllErrors |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Modelling Rule |

Description:Method to reset one error of the device.

Signature:

ResetErrorById(

[in]0:StringId);

Table 5 – ResetErrorById Method Arguments

|

Argument |

Description |

|

Id |

Id of the error, listed in ActiveErrors, that shall be reset. |

Table 6 – ResetErrorById Method AddressSpace Definition

|

Attribute |

Value |

||||

|

BrowseName |

ResetErrorById |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Modelling Rule |

|

HasProperty |

Variable |

InputArguments |

Argument[] |

PropertyType |

Mandatory |

Description:Method to set the cycle number of the LDS to synchronize it with the cycle number of the injection moulding machine.

Signature:

SetCycleNumber(

[in]0:UInt64CycleNumber);

Table 7 – SetCycleNumber Method Arguments

|

Argument |

Description |

|

CycleNumber |

Number, to which the cycle counter of the LDS shall be set. The next LDSCycleParametersEvent will use this value. |

Table 8 – SetCycleNumber Method AddressSpace Definition

|

Attribute |

Value |

||||

|

BrowseName |

SetCycleNumber |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Modelling Rule |

|

HasProperty |

Variable |

InputArguments |

Argument[] |

PropertyType |

Mandatory |

Type of the material balance system.

Table 9 – MaterialBalanceSystemTypeEnumeration

|

Name |

Value |

Description |

|

NOT_AVAILABLE |

0 |

No material balance system available on the LDS. ActivateMaterialBalanceSystem is not present, because it is not possible to switch a material balance system on |

|

ALWAYS_ACTIVE |

1 |

Material balance system is available on the LDS and always active. ActivateMaterialBalanceSystem is not present, because it is not possible to switch a material balance system off |

|

SELECTABLE |

2 |

Material balance system is available on the LDS and it can be switched on and off via the interface via the present ActivateMaterialBalanceSystem. |

If the value is true, the material balance system is activated.

The dosing system works with delivery pressure or volumetric flow. As some LSR dosing systems support the selection of the DeliveryType, the Property can be writeable. Therefore, the TypeDefinition is MultiStateValueDiscreteType, so the Properties EnumValues and ValueAsText must be filled with the supported values out of Table 10.

Table 10 – Values for DeliveryType

|

EnumValue |

ValueAsText |

Description |

|

0 |

PRESSURE |

Dosing system with delivery pressure |

|

1 |

VOLUMETRIC_FLOWRATE |

Dosing system with volumetric flow |

A server can provide manufacturer specific values with EnumValues ≥ 100.

With the objects DeliveryPressure and DeliverPressureMeasuringPoint the client can set (and monitor) the delivery pressure of the LDS. Both are optional, but the two elements shall always be used together.

For systems with DeliveryPressure the components ActualValue, SetValue, UpperTolerance and LowerTolerance defined in the ControlledParameterType are mandatory. If the upper or lower tolerance band is passed it is documented in the ErrorStatus.

Unit: bar or psi (=lbf/in²)

The variable DeliveryPressureMeasuringPoint represents the position of the pressure sensor used for the DeliveryPressure. As some LSR dosing systems support the selection of the position, the Property can be writeable. Therefore, the TypeDefinition is MultiStateValueDiscreteType, so the Properties EnumValues and ValueAsText must be filled with the supported values out of Table 11.

Table 11 – Values for PressureMeasuringPoint

|

EnumValue |

ValueAsText |

Description |

|

0 |

PUMP_A |

Pressure sensor position pump A |

|

1 |

PUMP_B |

Pressure sensor position pump B |

|

2 |

BLENDER |

Pressure sensor position blender |

|

3 |

MANUAL |

Pressure is manually adjusted |

A server can provide manufacturer specific values with EnumValues ≥ 100.

NOTE: The actual pressure for each component (for monitoring) is included in the ComponentType and the cyclic events.

For system with delivery volumetric flow rate the components ActualValue, SetValue, UpperTolerance and LowerTolerance are mandatory. If the upper or lower tolerance band is passed it is documented in the ErrorStatus.

Unit: l/h or gal/h

Specifies the value determined by the feeder as the shot weight.

Unit: g or lb

Reference value determined by the IMM or defined by the user on the IMM side.

Unit: g or lb

The composite set point of density.

Unit: g/cm³ or lb/in³

Target of the mixing ratio (includes ratio change when MaterialBalanceSystem is active). The share of component A (in percent) defines the value:

Examples:50 (A 50 : 50 B) without MaterialBalanceSystem

51,25 (A 51,25 : 48,75 B) active MaterialBalanceSystem

If a material balance system is used these variables are used to set and monitor the deviation from the set mixing ration of component A and B.

MaxDeviationMixingRatio is writeable by the client and used to limit the maximum deviation in percent.

TargetDeviationMixingRatio: This deviation (in percent) is set/used by the material balance system

ActualDeviationMixingRatio: Actual deviation (in percent)

The values are given related to the mixing ration of component A. If the maximum allowed mixing ration is 51% component A and 49% component B MaxDeviationMixingRatio is 1%.

Remaining time until first material is empty.

Depending on this preselected PurgeMode, various purge function can be activated via the dosing signal of the IMM.

Table 12 – Values for PurgeMode

|

EnumValue |

ValueAsText |

Description |

|

0 |

OFF |

No purge function. Normal dosing via dosing signal. |

|

1 |

WITH_COMPONENT_A |

Purge A |

|

2 |

WITH_COMPONENT_B |

Purge B |

|

3 |

WITH_COMPONENT_A_B |

Venting |

|

4 |

WITH_COMPONENT_A_OR_B |

System choose the component which is used for purging (usually the component with the larger remaining quantity) |

|

5 |

CYCLIC_COMPONENT_A_B |

Purge A and B cyclic |

Actual status of the purge function. PurgeStatus must show OFF if no purge function is active.

Purge functions can be activated by the operator or via dosing signal of the IMM depending on the PurgeMode.

Table 13 – PurgeStatusEnumeration

|

Name |

Value |

Description |

|

OFF |

0 |

No purge function is active. |

|

COMPONENT_A |

1 |

Purge component A is active. |

|

COMPONENT_B |

2 |

Purge component B is active. |

|

COMPONENT_A_AND_B |

3 |

Venting |

|

COMPONENT_A_AND_B_CYCLIC |

4 |

Cyclic purge component A and B is active. |

It is necessary to synchronize the dosing between IMM and LSR dosing systems. This can be done via a separate interfaces e.g. via hardwired signals or also via OPC UA (if the process is robust against small time delays that can be caused by the client/server-connection)

With ActivateRemoteControl the client selects the method of remote control. If the server provides only on method for remote control, the other one is not listed in the possible values of the MultiStateValueDiscreteType.

Table 14 – Values for ActivateRemoteControl and RemoteControlActivated

|

EnumValue |

ValueAsText |

Description |

|

0 |

OFF |

Remote control / automatic mode switched off. |

|

1 |

SEPARATE_INTERFACE |

Activating automatic mode on LDS and using a separate interface from the injection moulding machine for remote control |

|

2 |

OPC_UA |

Activating automatic mode on LDS and using this OPC UA connection with the method StartDosing for remote control |

A server can provide manufacturer specific values with EnumValues ≥ 100.

With this signal, the LDS signalizes, if it is ready to be controlled via this or a separate interface. See Table 14 for possible values.

Description:If RemoteControlActivated = 2, these Methods (without arguments) are used to start and stop the dosing.

NOTE: The dosing can also be stopped by the LDS itself (e.g. when SetShotWeight has been reached) to avoid evelasting dosing when the client does not call the method StopDosing.

Signatures:

StartDosing();

StopDosing();

The methods have no Input- or OutputArguments.

Table 15 – StartDosing Method AddressSpace Definition

|

Attribute |

Value |

||||

|

BrowseName |

StartDosing |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Modelling Rule |

Table 16 – StopDosing Method AddressSpace Definition

|

Attribute |

Value |

||||

|

BrowseName |

StopDosing |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Modelling Rule |

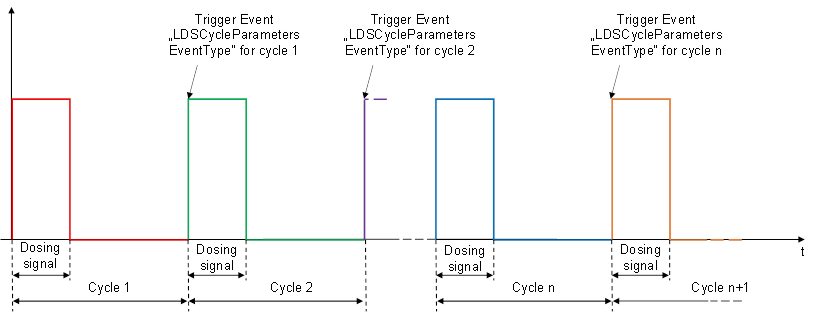

The LDSCycleParametersEventType represents information on a dosing cycle. A complete dosing is defined from the beginning of the dosing signal to the next one, i.e. the event for cycle n is fired, when the dosing signal for cycle n+1 starts.

Figure 2 – Timing of LDSCycleParametersEventTyps

The LDSCycleParametersEventType is formally defined in Table 17.

Table 17 – LDSCycleParametersEventType Definition

|

Attribute |

Value |

||||

|

BrowseName |

LDSCycleParametersEventType |

||||

|

IsAbstract |

True |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of 0:BaseEventType defined in OPC UA Part 5 |

|||||

|

0:HasProperty |

Variable |

CycleNumber |

0:UInt64 |

0:PropertyType |

M |

|

0:HasProperty |

Variable |

DosingTime |

0:Duration |

0:PropertyType |

O |

|

0:HasComponent |

Variable |

MixingRatioTarget |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

MixingRatioActual |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

AdditivesRatioTarget |

0:Double[] |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

AdditivesRatioActual |

0:Double[] |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeA |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeB |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeAB |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeAdditives |

0:Double[] |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeTotal |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

ResidualAmountA |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

ResidualAmountB |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

MixingPointPressureA |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

MixingPointPressureB |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

MixingPointPressureBlender |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

AdditivesPressure |

0:Double[] |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

FilterPressurePrimary |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

FilterPressureSecondary |

0:Double |

0:AnalogItemType |

O |

Number of the dosing cycle. Gets counted up after each dosing cycle.

Example: 900

Duration of the dosing cycle.

Target mixing ratio of the last cycle (includes ratio change when MaterialBalanceSystem is active). The share of component A (in percent) defines the value:

Examples:50 (A 50 : 50 B) without MaterialBalanceSystem

51,25 (A 51,25 : 48,75 B) active MaterialBalanceSystem

Actual mixing ratio of the components. The share of component A defines the value:

Example: 50,9(A 50,9 : 49,1 B)

Target ratios of additives in percentage which are set in AdditiveFraction of AdditiveType.

Actual ratios of additive in percentage.

Example: [ 2,1 % ; 1,2 % ]

Volume of component A that was added to the process in the last cycle.

Unit: cm³ or in³

Volume of component B that was added to the process in the last cycle.

Unit: cm³ or in³

Volume of components A + B that was added to the process in the last cycle.

Unit: cm³ or in³

Volumes of the additives that were added to the process in the last cycle

Unit: cm³ or in³

Volume of all components (A + B + all additives)

Unit: cm³ or in³

Residual weight amount of component A at the end of the dosing cycle.

Unit: kg or lb

Residual weight amount of component B at the end of the dosing cycle.

Unit: kg or lb

Average pressure of component A during the last cycle at the blender.

Unit: bar or psi

Average pressure of component B during the last cycle at the blender.

Unit: bar or psi

Average pressure of components A&B during the last cycle at the blender.

Unit: bar or psi

Average pressure of the additive during the last cycle at the measuring point.

Unit: bar or psi

Average material pressure during the last cycle before and after the filter. The Pressure difference between FilterPressurePrimary & FilterPressureSecondary can be used to check if the filter is blocked/ will be blocked soon/ has to be maintained. Unit: bar or psi