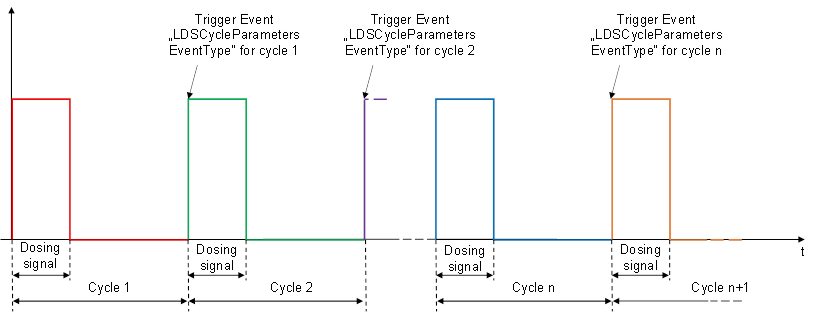

The LDSCycleParametersEventType represents information on a dosing cycle. A complete dosing is defined from the beginning of the dosing signal to the next one, i.e. the event for cycle n is fired, when the dosing signal for cycle n+1 starts.

Figure 2 – Timing of LDSCycleParametersEventTyps

The LDSCycleParametersEventType is formally defined in Table 17.

Table 17 – LDSCycleParametersEventType Definition

|

Attribute |

Value |

||||

|

BrowseName |

LDSCycleParametersEventType |

||||

|

IsAbstract |

True |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of 0:BaseEventType defined in OPC UA Part 5 |

|||||

|

0:HasProperty |

Variable |

CycleNumber |

0:UInt64 |

0:PropertyType |

M |

|

0:HasProperty |

Variable |

DosingTime |

0:Duration |

0:PropertyType |

O |

|

0:HasComponent |

Variable |

MixingRatioTarget |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

MixingRatioActual |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

AdditivesRatioTarget |

0:Double[] |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

AdditivesRatioActual |

0:Double[] |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeA |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeB |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeAB |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeAdditives |

0:Double[] |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

VolumeTotal |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

ResidualAmountA |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

ResidualAmountB |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

MixingPointPressureA |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

MixingPointPressureB |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

MixingPointPressureBlender |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

AdditivesPressure |

0:Double[] |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

FilterPressurePrimary |

0:Double |

0:AnalogItemType |

O |

|

0:HasComponent |

Variable |

FilterPressureSecondary |

0:Double |

0:AnalogItemType |

O |

Number of the dosing cycle. Gets counted up after each dosing cycle.

Example: 900

Duration of the dosing cycle.

Target mixing ratio of the last cycle (includes ratio change when MaterialBalanceSystem is active). The share of component A (in percent) defines the value:

Examples:50 (A 50 : 50 B) without MaterialBalanceSystem

51,25 (A 51,25 : 48,75 B) active MaterialBalanceSystem

Actual mixing ratio of the components. The share of component A defines the value:

Example: 50,9(A 50,9 : 49,1 B)

Target ratios of additives in percentage which are set in AdditiveFraction of AdditiveType.

Actual ratios of additive in percentage.

Example: [ 2,1 % ; 1,2 % ]

Volume of component A that was added to the process in the last cycle.

Unit: cm³ or in³

Volume of component B that was added to the process in the last cycle.

Unit: cm³ or in³

Volume of components A + B that was added to the process in the last cycle.

Unit: cm³ or in³

Volumes of the additives that were added to the process in the last cycle

Unit: cm³ or in³

Volume of all components (A + B + all additives)

Unit: cm³ or in³

Residual weight amount of component A at the end of the dosing cycle.

Unit: kg or lb

Residual weight amount of component B at the end of the dosing cycle.

Unit: kg or lb

Average pressure of component A during the last cycle at the blender.

Unit: bar or psi

Average pressure of component B during the last cycle at the blender.

Unit: bar or psi

Average pressure of components A&B during the last cycle at the blender.

Unit: bar or psi

Average pressure of the additive during the last cycle at the measuring point.

Unit: bar or psi

Average material pressure during the last cycle before and after the filter. The Pressure difference between FilterPressurePrimary & FilterPressureSecondary can be used to check if the filter is blocked/ will be blocked soon/ has to be maintained. Unit: bar or psi