Automation does not end with equipment control; it also includes higher levels of control that manage personnel, equipment, and materials across production areas. Effectiveness in manufacturing companies is not based solely on equipment control capability. The ISA-95 Enterprise/Control System Integration standard defines 5 levels of activities in a manufacturing organization. Generally, automation and control support Levels 1 and 2, Manufacturing Operations Management (MOM) systems support Level 3, and business Enterprise Resource Planning (ERP) systems support Level 4 activities. ISA-95 defines four primary types of information that often must be exchanged among MOM systems and between ERP systems and MOM systems, these types are;

- Information about material and the properties of materials,

- Information about equipment as it pertains to the operations being performed,

- Information about the physical assets that make up the equipment,

- Information about personnel and their roles and qualifications.

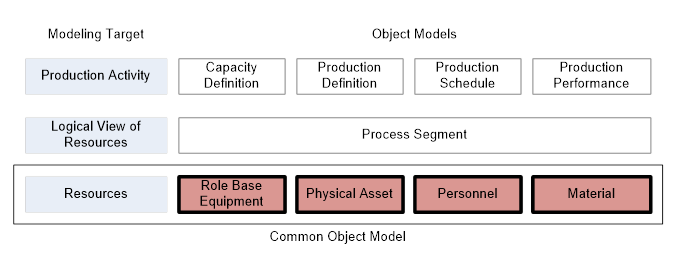

ISA-95 provides a standard manner to uniquely describe this information for exchange, including the interrelationships between the various types of information. The ISA-95 standard is described in multiple parts, where each part describes a portion of the standard. The 2010 versions of Parts 1 and 2 of the ISA-95 standard have been used to define a UA companion standard using OPC UA constructs for the purpose of exposing the ISA-95 objects and attributes in an OPC UA environment. This first release of the UA companion standard supports a subset of the entire ISA-95 standard, covering the role based equipment, physical asset, material and personnel object models in ISA-95 (see Figure 1). Later revisions of the companion standard may include support for the other ISA-95 object models such as process segment, operations definition, operations schedule, operations performance and operations capability object models.