For an OPC UA user that may not be familiar with ISA-95, the following section provides a brief overview of key features that ISA-95 provides along with a little background related to ISA-95 and the concepts behind it.

Typically in a manufacturing world plants optimize their control systems to maximize production and profits. Manufacturing companies must also be efficient at coordinating and controlling personnel, materials, and equipment across different control systems in order to reach their maximum potential. This coordination and control must occur in at least four different parts of an organization; production, quality tests and test labs, warehousing and inventory management, and maintenance.

This coordination and control is often supported by Manufacturing Execution Systems (MES) for management of production operations, Laboratory Information Management Systems (LIMS) for quality tests and test lab management, Warehouse Management Systems (WMS) or Tank Farm Management systems for management of inventory operations, and Asset Management or Computerized Maintenance Management Systems (CMMS) for maintenance operations. These systems together are collectively called Manufacturing Operations Management (MOM) systems. MOM defines a diverse set of functions that operate above automation control systems, reside below the level of enterprise business systems and are local to a site or area.

ISA-95 was created to allow efficient sharing and coordination of information between the various levels. The following subsections summarize the information that needs to be exchanged.

Sharing Material Information: Manufacturing requires materials. It is not surprising that manufacturing systems have a requirement to identify and track materials because the main purpose of manufacturing is to convert materials in one form into materials of another form. An important part of MOM integration is maintaining and exchanging material identification and information.

- MES identify materials and their suitability for use, batch management systems confirm that the correct materials are used as specified in the recipes,

- Tracking and tracing systems (bar-code scanners and RFID readers),

- LIMS confirm that the correct materials are tested and the correct materials are used in testing,

- WMS identify materials in their storage locations.

- Shared material information can be divided into three main categories;

Sharing Equipment Information: One important element of managed information is the correct identification of the equipment used for manufacturing. Equipment identification is used for:

- scheduling,

- tracking and tracing,

- maintenance,

- troubleshooting,

- visualization (HMI),

- capacity tracking,

- OEE (Overall Equipment Effectiveness) calculations.

Unfortunately, it is not uncommon for a manufacturing company to have multiple identifications for a single piece of equipment. Therefore, a critical aspect of equipment information management is managing different equipment ID’s across multiple vendor systems and applications.

Sharing Physical Asset Information: Identification of a unique physical asset, irrespective of the role the equipment is performing is vital for:

- maintenance,

- equipment qualification and regulatory compliance,

- financial asset tracking

While equipment is typically identified by a tag, such as TT-101 for a temperature transmitter, that identifies the role, or current function, of a specific asset physical asset information this is not sufficient for tracking individual assets for maintenance and financial purposes. To manage assets a company must have a unique identifier for the physical asset that is independent of the role it serves at a specific point in time. For example temperature transmitter TT-101 may have a serial number of X2 on a specific day, the next day the transmitter may be swapped out with a replacement transmitter with the same specifications but with the serial number X3. X3 would then be configured to have the tag TT-101 and X2 would no longer be known as TT-101. In order to track the transmitters X2 and X3 the physical asset information model would be used, while for operations purposes it is only important that TT-101 is in use and providing a temperature reading, the operators and control systems do not generally need to know the asset tag of TT-101, they just need the tag.

Tracking of individual physical assets allows companies to monitor individual asset’s health records, ensure they are qualified for production and track them in financial systems.

Sharing Personnel Information: Multiple regulatory rules, laws, and internal procedures require that personnel who perform shop floor actions are unequivocally identified, are authorized to perform the actions, and have valid training or qualifications to perform the actions. Because personnel information is usually maintained in multiple IT systems and control systems, it is a key area of exchanged information. Specific uses in different systems that require coordination and sharing include:

- MES Personnel qualification to be checked before someone is allowed to take an action

- LIMS Identification of approved personnel to perform tests and handle materials, often based on their training qualifications,

- AM Certification information about personnel performing maintenance activities to ensure that they have the proper training required by the activity,

- WMS Certification that personnel are trained and qualified to handle material movement systems, such as fork trucks or crane systems.

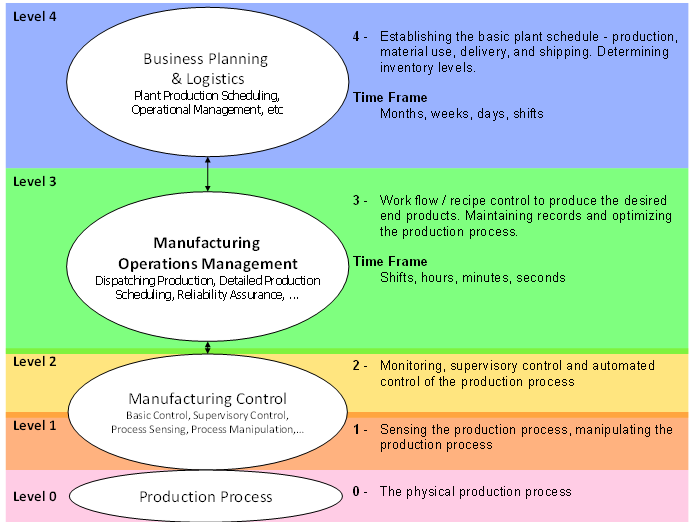

The ISA-95 Enterprise/Control System Integration standard defines five levels of activities in a manufacturing organization. Generally, automation and control support Levels 1 and 2, MOM systems support Level 3, and business Enterprise Resource Planning (ERP) systems support Level 4 activities. The ISA-95 levels are shown in Figure 1.

- Level 0 defines the actual physical processes.

- Level 1 elements are the sensors and actuators attached to the control functions in automation systems.

- Level 2 automation and control systems have real-time responses measured in sub-seconds and are typically implemented on Programmable Logic Controllers (PLC), Distributed Control Systems (DCS), and Open Control Systems (OCS).

- Level 3 typically operates on time frames of days, shifts, hours, minutes, and seconds. Level 3 functions also include maintenance functions, quality assurance and laboratory functions, and inventory movement functions, and are collectively called Manufacturing Operations Management. A wide variety of systems support the activities, including SCADA (Supervisory Control and Data Acquisition) systems for monitoring the process and providing operator control, batch control systems for execution of recipes, data historians for the collection and preservation of time based data from Level 2 systems, recipe and document management systems for managing recipes and workflow instructions, detailed scheduling, campaign management or work dispatching, and work or product tracking.

- Level 4 typically operates on time frames of months, weeks, and days. Enterprise Resource Planning (ERP) logistics systems are used to automate Level 4 functions. Level 4 is called Business Planning and Logistics.

Figure 2 - Five Activity Levels in Business

It is important to remember that each level has some form of control and each level has its own definition for real-time. Level 3 systems consider real-time to mean information available a few seconds after shop floor events occur. Level 4 systems consider real-time to mean that logistics and material information is available daily or within a few hours after the end of a shift.

ISA-95 typically deals with information exchange across Level 3 systems or between Level 3 and Level 4 systems. Specifically this would involve information exchange between ERP, EAM, CMMS, MES, WMS, LIMS, PLC and DCS systems. This information exchange in real-time is often required in order to allow workflows and recipes to execute in a timely manner. ISA-95 defines four primary types of information that often must be exchanged among MOM systems and between ERP systems and MOM systems, these types are; information about material and the properties of materials, information about equipment as it pertains to the operations being performed, information about the physical assets that make up the equipment, and information about personnel and their roles and qualifications.

The ISA-95 modelling approach to information is based on a “Property” model. [Note this is an ISA Property not a Property as defined by OPC UA] The ISA-95 models define a minimum set of industry-independent information as attributes. Industry specific, application specific, and company specific information are represented as property objects. For example, the personnel class property would be used to define application or industry specific attributes for personnel classes, and person property would be used to contain instance values for the properties.

In the ISA-95 resource models there are “Classes” and “Instances”. The word “Class” used as part of an object definition name should be considered as a classification, not as a “Class” in the official UML Modelling definition. For example: “Personnel Class” should be considered a “Personnel Classification”, because it is used to distinguish between the kinds of personnel in the real world and to define properties that would be common to personnel within the same classification. The UML description of each of the ISA Information models is described. The ISA-95 Model also includes definitions of common attributes. These definitions are not part of the UML figures, but are included as text in the ISA-95 specification.

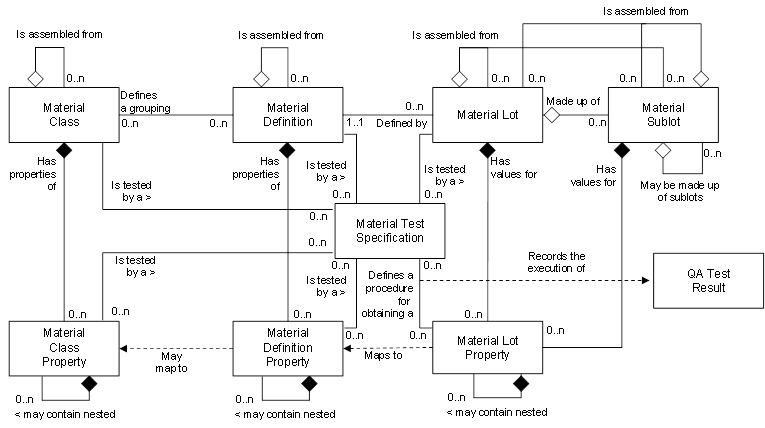

Material: is from ISA-95.00.02, it is the ISA-95 material object model. This is the definition of the lots, sublots, material definitions, and material classes involved in production. This information allows Level 3 and Level 4 systems to unambiguously identify material specified in production schedules and consumed or produced in actual production. A prime business driver for using the material model is to provide the ability to trace all materials used in the manufacture of a product to aide in quality analysis and product recalls.

Each Material Definition instance defines a type of material, such as Acetic Acid, grade 4. Each Material Definition may have specific properties, such as pH. These properties can be nested, in that a property can have its own properties. Material Definitions may be assembled from other Material Definitions, as in the case of a sub-assembly in car manufacturing, such as a transaxle which is identified as a Material Definition but is pre-assembled from multiple other Material Definitions. The sub-assembly record keeping is important to maintain traceability.

Material Definitions may belong to a Material Class. Material Classes are used as logical groups to manage Material definitions. Material Classes also have properties that can be nested and may also use the same assembly construct as used by Material Definitions.

Each Material Lot is an instance of a Material Definition that is uniquely identified. Material Lots also have properties that can be nested and may also use an assembly construct similar to that used by Material Definitions, the difference is that a Material Lot may be assembled from other Material Lots and/or Material Sublots. Material Lot instance properties are typically used to track specific shipments or orders of material.

Each Material Sublot is an instance of a Material Definition that is uniquely identified. Material Sublots do not have properties since each sublot instance must have the same properties as the Material Lot it is part of. Material Sublots may also use the same assembly construct as used by Material Lots. Material Sublot instances are typically used to provide tracking resolution within Material Lots, for example a Material Lot may have been received from a vendor in ten barrels, each barrel may be identified as a separate Material Sublot in order to track its movements and environmental conditions during storage and production.

The Material Test Specification identifies a test that may be associated with determining the value for a property of a Material Class, Material Definition or Material Lot instance. The information obtained from running the test can be modelled in the QA Test Result.

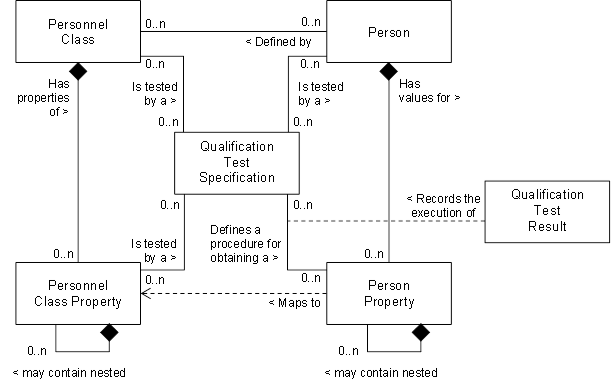

Personnel: Figure 2 is from ISA-95.00.02, it is the ISA-95 personnel object model. This is the definition of the persons and personnel classes (roles) involved in production. This information may be used to associate production with specific persons as part of a production record, or with personnel classes to allocate production costs.

Each instance of the Personnel Class from ANSI/ISA-95.00.02, is the Personnel object model. Each instance of the Personnel Class defines a role that a person can perform, such as a Draftsman. Each role may have specific properties, such as a Drafting License Number and a License Expiration Date. These Properties can also have their own nested properties. Each Person can be associated to one or more Personnel Class Roles. If the person is a Draftsman, then the Person Properties define the values for the Drafting License Number and License Expiration Date for that person. The Qualification Test Specification identifies a test that may be associated with determining the value for a property (such as a test for Draftsman used to obtain a Drafting License Number.) The information obtained from taking the test can be modelled in the Qualification Test Result.

This modelling approach for ISA-95 means that properties must be able to be dynamically queried and browsed. The properties available for individual objects will be different, for example in Figure 22 - Personnel Overview, Joe Smith has a Drafting License Number, but Sally Jones does not.

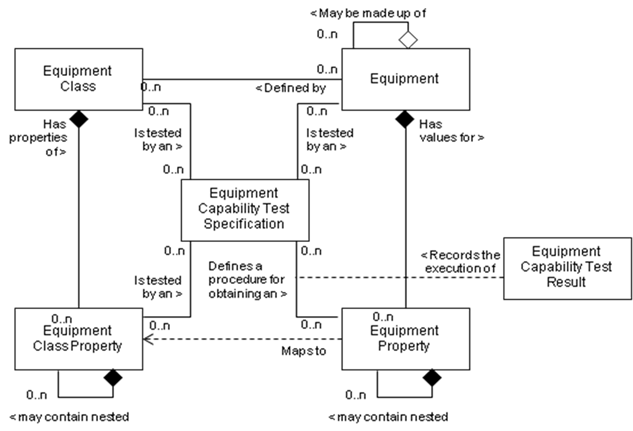

Equipment: Figure 5 is, from ISA-95.00.02, it is the equipment object model. This is the definition of the roles that equipment and equipment classes perform in production, inventory management, and quality test labs. This information may be used to associate production with specific equipment as part of a production record, or with equipment classes to schedule production and allocate costs

Each instance of the Equipment Class defines a classification of equipment, such as a tank. Each Equipment Class may have specific properties, such as a volume. These properties can be nested, in that a property can have its own properties. Each piece of Equipment can be associated to one or more Equipment Classes. If the Equipment is a tank, then the Equipment Properties define the values for the volume of the tank. Equipment can also be nested, in that they can contain other Equipment. The tank may also include several sensors such as temperature. The modeller can choose between extra properties or next properties and nest equipment depending on their own criteria. The Equipment Capability Test Specification identifies a test that may be associated with determining the value for a property. The information obtained from running the test can be modelled in the Equipment Capability Test Result.

The Modelling approach for ISA-95 results in multiple levels of Equipment and Equipment Classes. By definition if an Equipment is defined by an Equipment Class then it will have Equipment Properties that correspond to the Equipment Class Properties in the defining Equipment Class.

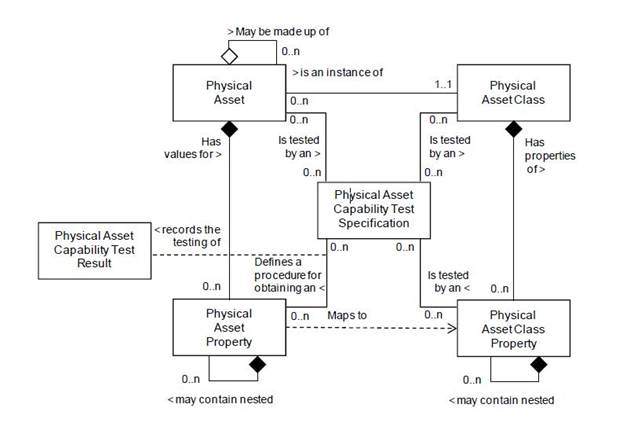

Physical Assets: Figure 6 is from ISA-95.00.02, it is the physical asset object model. This is an identification of the specific physical asset (by serial number or asset ID) used in manufacturing operations. It also includes the make and model information that identifies the type of physical asset and its properties.

Each instance of the Physical Asset Class defines a classification of Physical Asset, such as a valve. Each class may have specific properties, such as a percent open. These properties can be nested, in that a property can have its own properties. Each Physical Asset is associated to one Physical Asset Classes. This relationship is more like a type of, for example a car would be a Porsche 911 Carrera S, and it could not also be any other model. If the Physical Asset is a car, then the Physical Asset Properties define the values for the colour of the car and maybe the option package associated with the car. The option package would have its own properties such as leather interior, sun roof etc.. Physical Assets can also be nested, in that they can contain other Physical Assets. For example a Car would contain four tires that have their own Physical Asset Class. The Physical Asset Capability Test Specification identifies a test that may be associated with determining the value for a property. The information obtained from running the test can be modelled in the Physical Asset Capability Test Result.

Figure 6 - Physical Asset Model

The Modelling approach for ISA-95 results in multiple levels of Physical Assets. By definition if a Physical Asset is defined by a Physical Asset Class then it will have Physical Asset Properties that correspond to the Physical Asset Class Properties in the defining Physical Asset Class.

ISA-95 is an abstract specification in that it does not provide any implementation. Other organizations, such as MESA, have created an implementation (B2MML) of the ISA-95 standard. B2MML generated a mapping of the ISA-95 standard that is appropriate for the technology used in the mapping, but the mapping used does not in all cases map well to OPC UA. This specification generates a mapping based on the ISA-95 specification, and where possible it follows the B2MML mapping to allow an easier translation of a B2MML model to an OPC UA Model.

The ISA-95 Model also expects end users to generate a custom model that is based on the defined constructs. The resulting model contains a large amount of information and can require considerable time to develop. The ability to translate a B2MML model to an OPC UA model is an attempt to allow reuse of the extended effort to define a B2MML model.