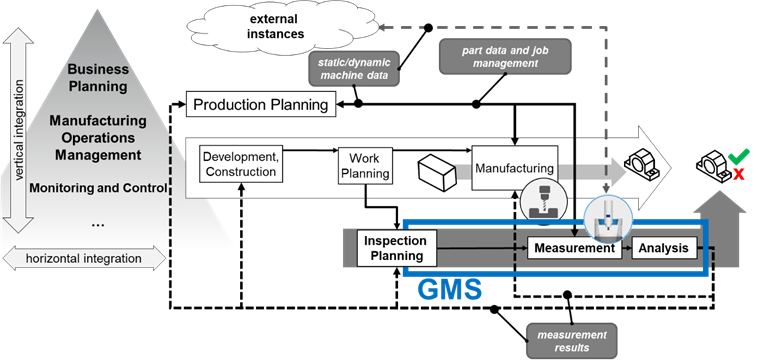

This companion specification describes how a GMS is addressed via OPC UA. For this purpose, the following primary use cases for the communication with a GMS are considered in sections 6.1 to 6.56.5. These use cases are located in the overview figure of a Geometric Measurement System (GMS) in Figure 9.

Further use cases can also be covered or specified in other standards (vendor or Companion Specification).

Figure 9 – Overview of a GMS and the Production Environment with the Primary Use Cases (in grey boxes)

In each chapter for the use cases, a simple sequence diagram demonstrates a typical communication example between GMS and other instances like operator, high-level system in the automation pyramid, data bases or other systems.

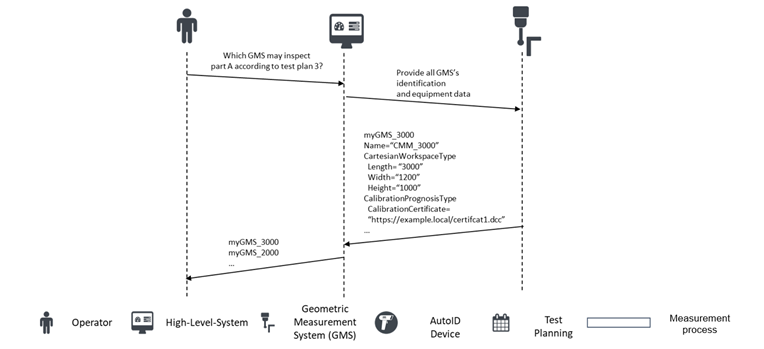

A higher-level system requests from a GMS which (measurement) functions/parameters (measuring space) are available, how the machine is identified if the measuring system is calibrated, retrieves additional information from machine components and, to receive an overview of the sensor system, respectively in order to

- provide an overview of GMS's capabilities

- validate measurement jobs addressed to a certain GMS

- plan measuring tasks for GMSs

- be able to locate all GMSs

- assign the appropriate GMS to the part to be measured, if several different GMSs are available

Figure 10 shows a typical communication between GMS, operator and high-level system to retrieve static machine data as a sequence diagram.

Figure 10 – Typical communication to retrieve static machine data

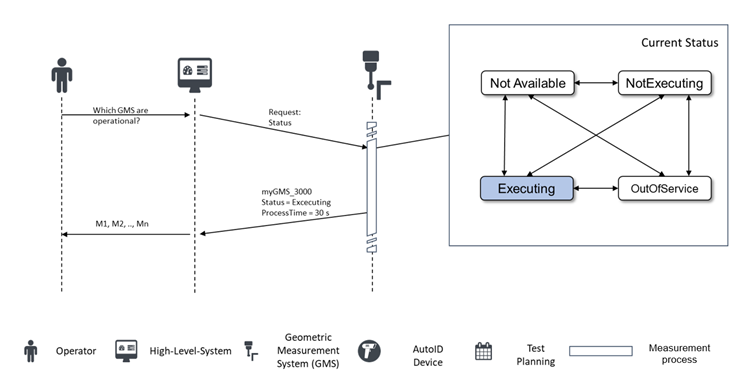

A higher-level system would like to know the status/state/condition (e.g., collision) of the GMS, when manual intervention is required, the current error message, what measures have to be taken in case of intervention to

- plan the next jobs

- keep usage statistics

- plan maintenance

- assign service

- calculate key performance indicators (e.g., OEE [ISO 22400-2])

- archive data

- verify the reliability of the measurements

- send warnings, if necessary.

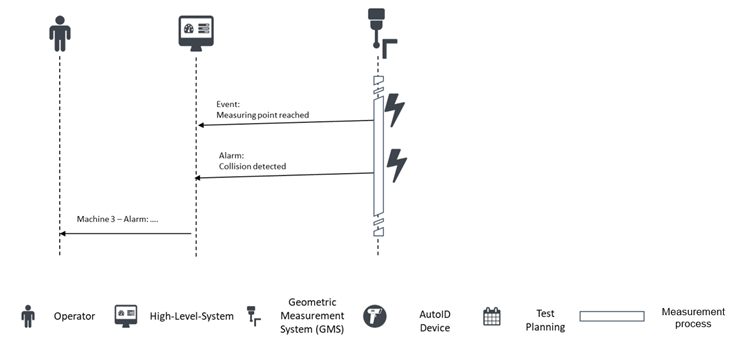

Figure 11 and Figure 12 show a typical communication between GMS, operator, and high-level system to retrieve dynamic machine data as a sequence diagram.

Figure 11 – Typical communication to retrieve dynamic machine data

Figure 12 – Typical communication to retrieve events or alarms

A higher-level system may manage/schedule/start/stop measurement routines, be able to assign part to a job/measurement routine/batch, want to know the remaining time till the job is finished, know what the current status of the job is and include dynamic part data in the measurement result (e.g., material no., part no., comments, operator) in order to

- be able to distribute the execution processes automatically

- (automatically) start/enable the measurement routine

- create an overview of the current job status

- ensure traceability

NOTE: In version 1.0 only the monitoring of jobs is implemented. The other aspects will be implemented in further versions as soon as the necessary concepts (e.g., in OPC UA for Machinery) are harmonized.

Figure 13 shows a typical communication between GMS, operator and high-level system to manage jobs as a sequence diagram.

Figure 13 – Typical communication to manage jobs

A higher-level system/handling system would like to identify a part on the GMS, know whether the measuring procedure was error-free, know when a measurement is finished as well as read and write meta-data (e.g., batch, temperature) in order to

- decide whether the part requires further processing, has to be sorted out, or the measurement has to be repeated

- annotate measured values with the meta-data and save them

- transmit these to the next production process

- request the GMS to load proper data to measure (e.g., measurement routine) a part

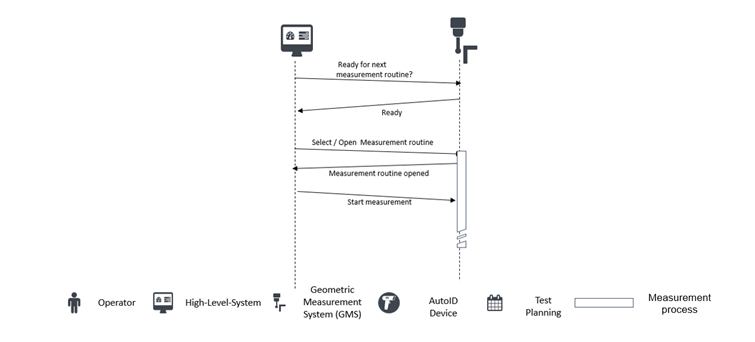

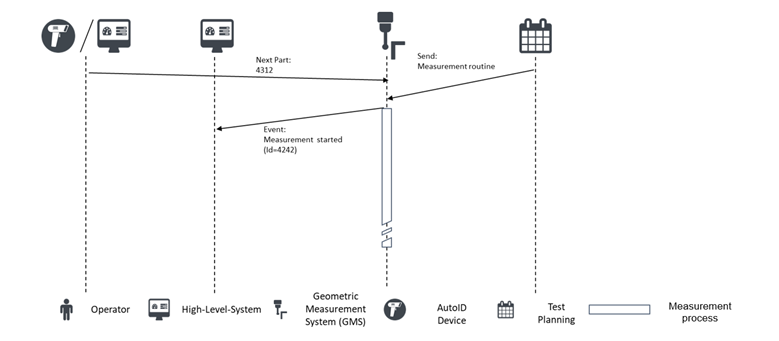

Figure 14 shows a typical communication between GMS, operator, and high-level system to manage part data as a sequence diagram.

Figure 14 – Typical communication to manage part data

A higher-level system would like to receive the measurement results (incl. meta-data) for a part in order to

- correct/adjust the program in the machine tool

- be able to guarantee complete traceability of the workpiece

- reject or rework the workpiece, if necessary

- release the products

- optimize the product

- interpret the product (e.g., statistical analyses)

- check the product quality

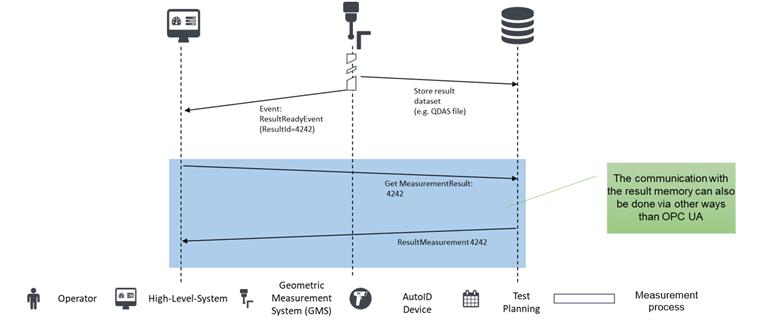

Figure 15 shows a typical communication between GMS, operator, and high-level system to retrieve measurement results as a sequence diagram.

Figure 15 – Typical communication to retrieve measurement results