A higher-level system may manage/schedule/start/stop measurement routines, be able to assign part to a job/measurement routine/batch, want to know the remaining time till the job is finished, know what the current status of the job is and include dynamic part data in the measurement result (e.g., material no., part no., comments, operator) in order to

- be able to distribute the execution processes automatically

- (automatically) start/enable the measurement routine

- create an overview of the current job status

- ensure traceability

NOTE: In version 1.0 only the monitoring of jobs is implemented. The other aspects will be implemented in further versions as soon as the necessary concepts (e.g., in OPC UA for Machinery) are harmonized.

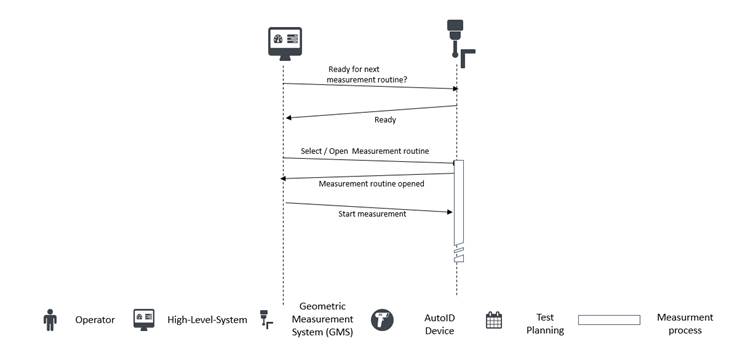

Figure 13 shows a typical communication between GMS, operator and high-level system to manage jobs as a sequence diagram.