Smart Industry is associated with next generation of manufacturing to increase efficiency, flexibility, and productivity. This also includes the broader interplay between the OT and IT domain as well as the further integration of services from different application areas. Technology domains such as from smart infrastructure and web forecasting services like traffic and weather forecasts are expected to be integrated directly into the manufacturing process as well as in the product lifecycle. To realize cross-domain applications for the Industrie 4.0 context, a frequent exchange with suppliers or local infrastructure providers (e.g., power supplier) is needed and it is necessary to interact with manufacturing systems that usally offers an OPC UA interface. WoT can act as a common and standardized application layer and can be used to support Industry 4.0 use cases. In this context, well-formed bindings for most established industry standards such as OPC UA should be supported.

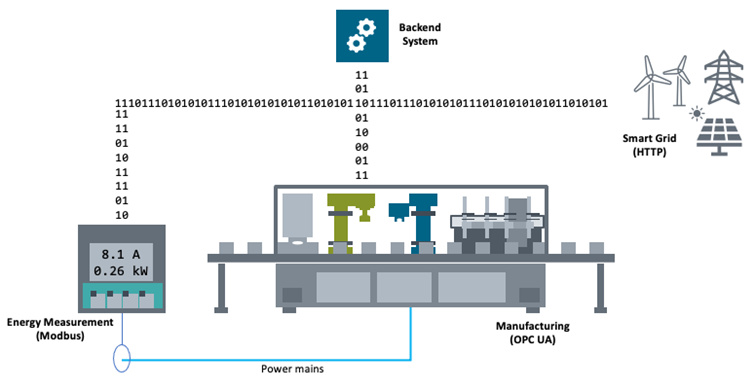

A bottling line consists of a filling module (switchable between 2 fillers and 4 fillers), a capping module, a labeling module, and a transport system. The production line is provided via an OPC UA endpoint for control and monitoring purposes.

In the context of enhancing productivity and sustainability, the goal is to operate the bottling line in such a way that production is further increased when sufficient or surplus renewable energy is available. The backend system checks periodically a Smart Grid endpoint (via HTTP) how the current power production is and how much renewable energy is produced. Based on the bottling line's current power consumption, which is measured via Modbus, the backend system decides to increase productivity when surplus renewable energy is available. In doing so, the backend system interacts via OPC UA to release the 4 fillers of the filling module and increases the speed of the transport system. If the backend system detects that less renewable energy is being produced, it will initiate standard production and reduce the transport speed and return the 2 fillers of the filling module.