The standardization and depiction of the wire harness machinery rely on several fundamental building blocks, namely:

- Identification

- ItemState

- ApplicationMode

- Job Management

- Result Management

In this sector-specific adaptation, both Job Management and Result Management are extended to meet unique industry needs, while the other building blocks are incorporated unchanged.

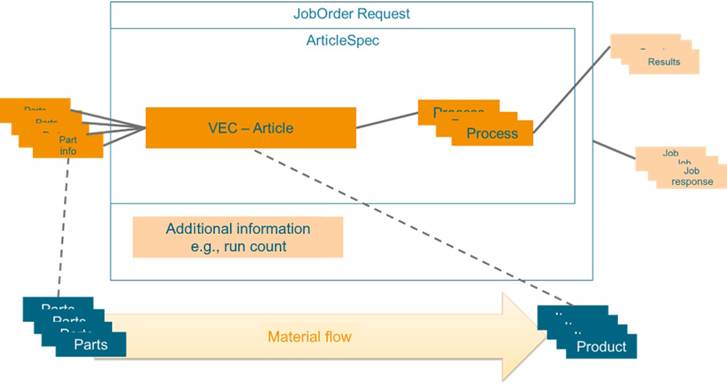

Figure 1 illustrates the schematic structure of a job in the wire harness domain and its interplay with the results and the actual assets involved.

Figure 1 – Abstract overview of a Wire Harness Job

To execute, or run a job, multiple parts are supplied to the machine and processed into products. A product aligns with a specification, referred to as 'ArticleSpec.' An ArticleSpec contains process information, article information, and a reference to the parts used (“Part info“ in the above image). Additionally, measurement results may be captured by the machine or the machine operator during setup and production. During setup, a set of verification measurements may be gathered that apply to the entire production lot. During production, a set of monitoring measurements may be collected for each item produced. The set of validation and monitoring processes are part of the article specification. These are understood within this specification to be processed on an instance-dependent basis. Each job can also have additional status information, which is stored in the Job Response (see OPC UA 40001-1).