The Weihenstephan Standards were developed within an industrial working group lead by the TUM. The main Use Cases of the WS do not change with the mapping to OPC UA since they are determined by the data points definied within these standards. However, OPC UA will add benefits in realizing these Use Cases as stated in chapter 4.1.

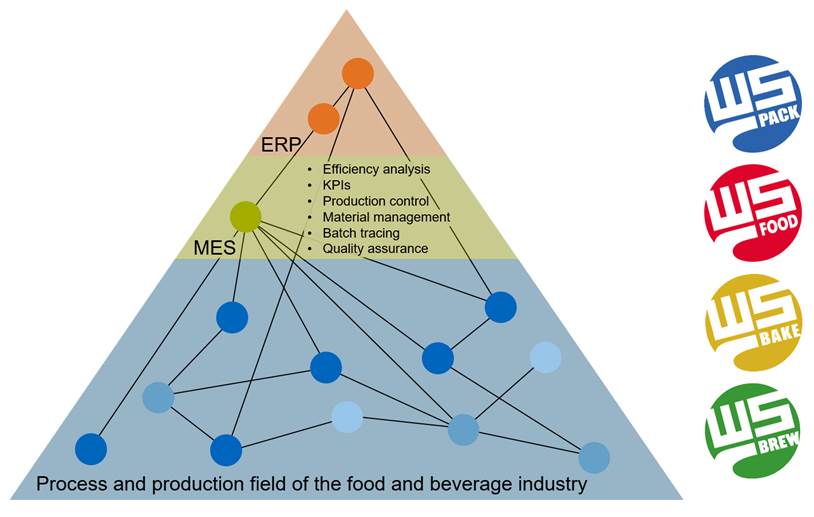

Figure 9 shows the three aspects covered by the Weihenstephan Standards:

- Exemplary definition of MES functionalities:

The WS define a variety of MES functionalities. Among other things, calculations of key figures for efficiency analyses, production control, but also functionalities for batch tracing and quality assurance are defined.

- Definition of the data points:

From the defined MES functionalities it can be derived which machine profiles need which data points for the calculation of the MES functions. These data points are described in detail within the WS.

- Specification of the communication interface:

The WS provides two communication interfaces for the transmission of data to the overlying MES: WS Protocol and WS OPC UA. The WS OPC UA communication interface is described in this document.

Figure 9 – WS connecting production and MES

The WS cover different domains within the field of Food Processing and Packaging Machinery through different specifications like WS Pack or WS Food. The data points are provided on the one hand by machine controllers (e.g. WS Pack) and on the other hand by the process control system (e.g. WS Brew). The deployment of the information model on a controller is possible with OPC UA, but can also be done on one of the supported platforms, e.g. as a Windows server within an IPC. As usual with an OPC UA Companion Specification, the deployment is not predetermined.