The import of a Descriptor with configuration information arises in the sharing of work between Controls Engineers: one Controls Engineer exports a Descriptor and sends it to another Controls Engineer for further usage.

The import could be for adding or changing the configuration of a Descriptor in a subsequent engineering step for the same AutomationComponent or using the information of the exported Descriptor for the configuration of another AutomationComponent, e.g., for configuring InputData from the OutputData information in a Controller-to-Controller communication scenario.

In both cases, the exported Descriptor with configuration information will be imported into an engineering tool. For the import, the same rules as in 8.3.2 apply.

In the case of subsequent engineering on the same AutomationComponent, data that was configured in a previous step may need to be changed.

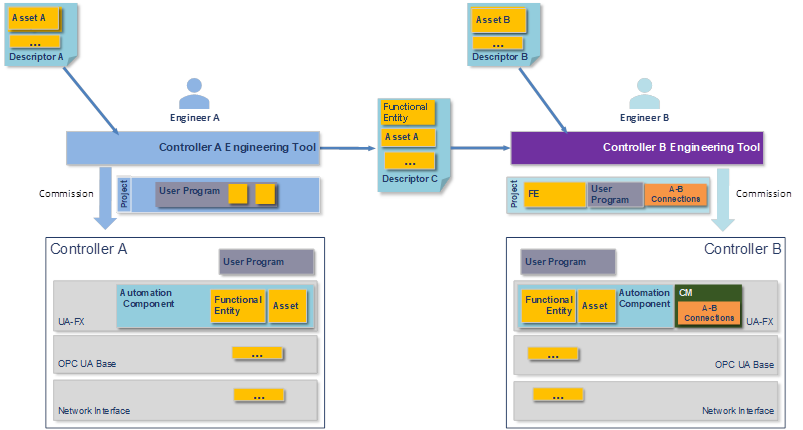

The OPC UA FX Connection Configuration workflow for a Controller-to-Controller application is illustrated in Figure 23.

Figure 23 – Engineering workflow for C2C Connection configuration

Figure 21 shows an engineering workflow where the task is to create a shared application where data is exchanged between Controller A and Controller B. It is assumed that the Controllers may be from different vendors or the same vendor.

In Figure 23, Descriptors are shared between the engineering tools in an export/import manner. The engineering tools consume the Descriptors. Descriptor C contains configuration information that shares the information it can provide to an AutomationComponent to allow meaningful communication. The yellow and orange boxes represent the information taken from the Descriptors by the engineering tools and downloaded together with the user programs into the Controllers.

The yellow FunctionalEntity and Asset boxes represent the Information Model of the AutomationComponent(s) in the Controllers. The FunctionalEntities contain input groups, output groups, data types, names, capabilities and other information (see OPC 10000-81 for full details). This information could contain the ranges and communication options available in the FunctionalEntities. The data types used in the communication must match between the Controllers.

The yellow boxes with the three dots contain additional information to be shared, e.g., information on network interfaces.

Engineer A creates a Descriptor with configuration information from Controller A's configuration data. This is done to share data with Engineer B to design the exchange of data between the AutomationComponents (e.g., Controller-to-Controller communication). Engineering tools are expected to support the engineer in this task. Engineer B can also share Descriptor information with Engineer A. This can be an iterative step that Controls Engineers can repeat several times as more information is added or changed during the creation process.