The following examples describe possible topologies based on different systems. There is no obligation to build the systems based on the following examples.

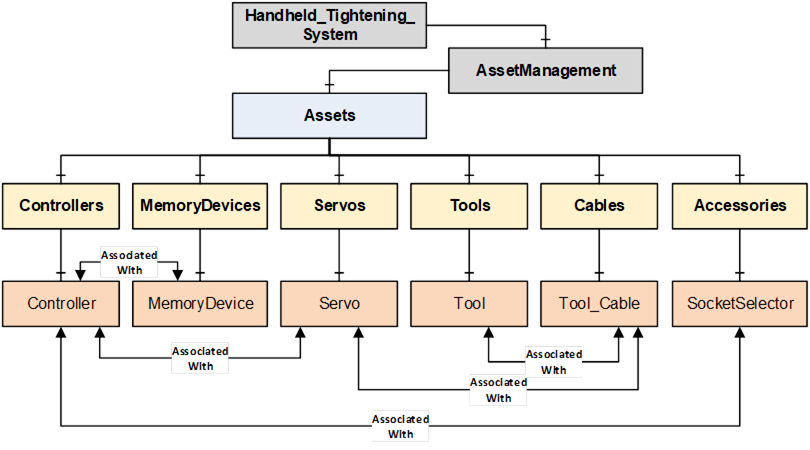

Handheld Tightening System Example

The following figure describes a basic Handheld Tightening System which consists of a handheld controller connected to a cable tool via a servo and cable. The controller has an attached memory device and it is also connected to a socket selector.

Figure 13 - Handheld Tightening System Example

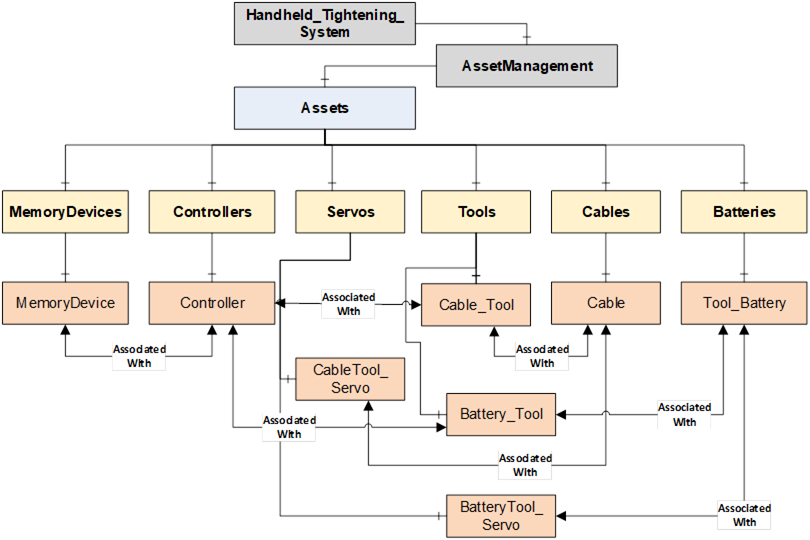

Handheld Tightening System with Battery Tool Example

The following figure describes a basic Handheld Tightening System which consists of a handheld controller connected to a cable tool via a servo and cable and a battery tool. The controller has an attached memory device and it is also connected to a socket selector.

Figure 14 - Handheld Tightening System with Battery Tool Example

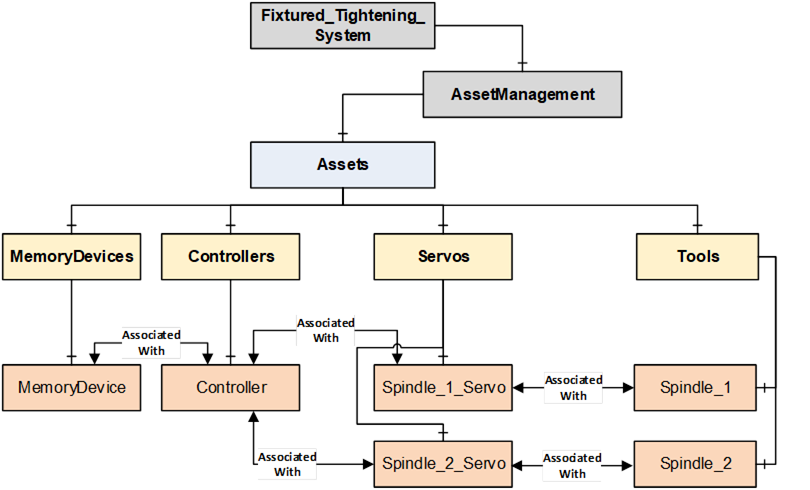

Fixtured Tightening System Example

The following figure describes a Fixtured Tightening System with two tightening spindles. Both the spindles are managed by one controller and it needs two servos to drive the two spindles. The controller has an attached memory device.

Note: This example does not model cables connected to spindles. There is no restriction in modeling a cable in the Fixtured Tightening System.

Figure 15 - Fixtured Tightening System Example

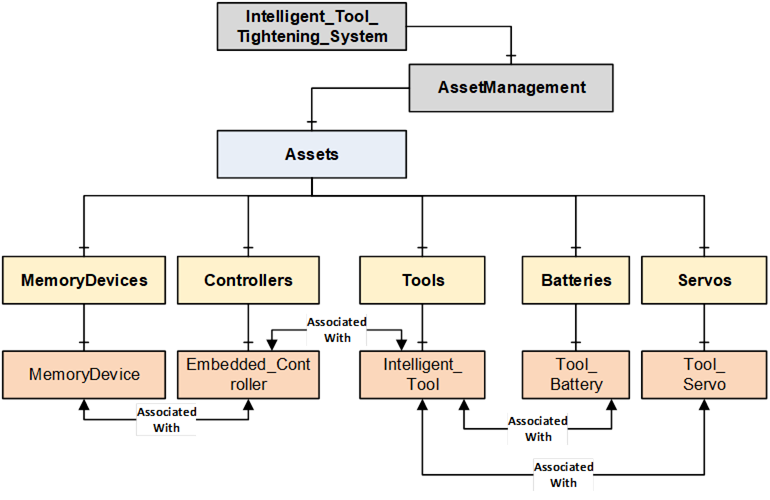

Intelligent Tool Tightening System Example

The following figure describes an Intelligent Tool Tightening System which consists of a Tool that has an embedded controller, servo and an attached memory device.

Figure 16 - Intelligent Tool Tightening System Example

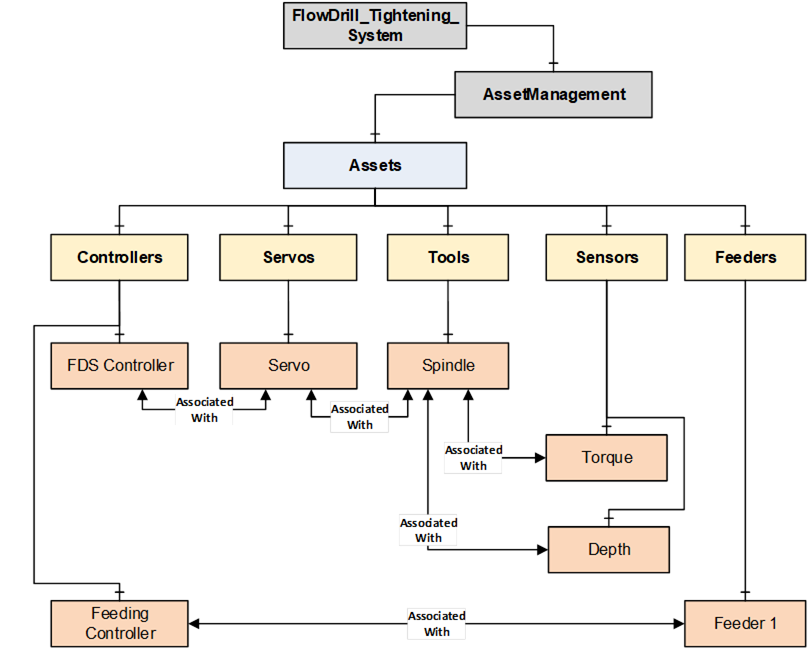

Flow Drill Tightening System Example

The following figure describes a Flow Drill Tightening System which consists of one spindle with one servo to drive in the screw. In the spindle there is a torque sensor to measure the torque at the screw and a depth sensor to measure the advancement of the screw into the part. Additionally, there is a feeding controller which ensures that the parts are available at the tightening location. The feeder stocks the fasteners and separates them.

Figure 17 - Flow Drill Tightening System Example

OPC UA References for Assets

An asset defined in the Tightening System can reference other assets in multiple ways such as Logical Connection, Network Connection, Physical Connection, Component (Attached Component, Built-in Component, Sub-Part, etc.), ConnectsTo, IsConnectedTo, etc.

For this version of the specification, only a generic reference AssociatedWith is used to enable the topological infrastructure which will be used by the client applications to build required tree view or hierarchies or a mesh of inter-linked nodes. There is no restriction on adding additional references.

Note: The assets model defined in Tightening System is flexible to cover various type of systems. For example, a Controller and MemoryDevice can have HasAttachedComponent or HasBuiltInComponent reference.

OPC UA base specifications may standardize different set of references which might be reused in the future versions of this specification.

Note: Table 109 provides few examples as general information which may be standardized in future versions of this specification or other common specifications.

Table 109 - OPC UA Reference Examples

|

Source Object |

Possible Reference Types |

Target Object |

|

Controller |

ConnectsTo IsConnectedTo IsPhysicallyConnectedTo |

Tool |

|

Controller |

ConnectsTo IsConnectedTo IsPhysicallyConnectedTo Controls |

Servo |

|

Controller |

ConnectsTo IsConnectedTo IsPhysicallyConnectedTo Controls |

Controller |

|

Controller |

HasAttachedComponent HasContainedComponent HasBuiltInComponent |

MemoryDevice |

|

Controller |

ConnectsTo IsConnectedTo IsPhysicallyConnectedTo Controls |

Feeder |

|

Controller |

HasAttachedComponent HasContainedComponent HasBuiltInComponent |

Sensor |

|

Controller |

ConnectsTo IsConnectedTo IsPhysicallyConnectedTo Controls |

Accessory |

|

Controller |

HasAttachedComponent HasContainedComponent HasBuiltInComponent |

SubComponent |

|

Tool |

ConnectsTo IsConnectedTo IsPhysicallyConnectedTo Controls |

Controller |

|

Tool |

HasAttachedComponent HasContainedComponent HasBuiltInComponent HasLogicalConnection |

Battery |

|

Tool |

HasAttachedComponent HasContainedComponent HasBuiltInComponent HasLogicalConnection |

Sensor |

|

Tool |

ConnectsTo IsConnectedTo IsPhysicallyConnectedTo Controls |

Accessory |

|

Tool |

HasAttachedComponent HasContainedComponent HasBuiltInComponent |

SubComponent |

|

Servo |

ConnectsTo IsConnectedTo IsPhysicallyConnectedTo |

Tool |

|

PowerSupply |

ConnectsTo IsConnectedTo IsPhysicallyConnectedTo |

Servo |

|

Battery |

ConnectsTo IsConnectedTo |

PowerSupply |

|

Battery |

ConnectsTo IsConnectedTo |

Servo |

|

Cable |

IsPhysicallyConnectedTo CommLinkTo |

Controller |

|

Cable |

IsPhysicallyConnectedTo CommLinkTo |

Servo |

|

Cable |

IsPhysicallyConnectedTo CommLinkTo |

Tool |

|

Cable |

IsPhysicallyConnectedTo CommLinkTo |

Feeder |

|

Cable |

IsPhysicallyConnectedTo CommLinkTo |

PowerSupply |

|

Cable |

IsPhysicallyConnectedTo CommLinkTo |

Sensor |

|

Cable |

IsPhysicallyConnectedTo CommLinkTo |

Accessory |

|

Cable |

IsPhysicallyConnectedTo CommLinkTo |

SubComponent |