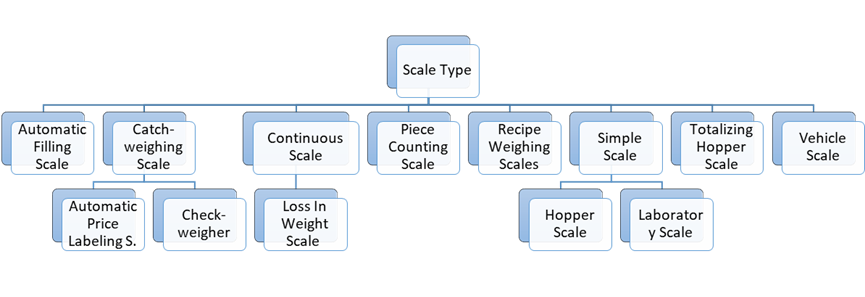

This classification of the scales is based on the aspect of communication via OPC UA. If possible, existing classifications (e.g. from OIML) were used. However, further conflicting classifications may exist. Since the boundaries are partly fluid, some devices can be assigned to several scale types. The resulting classification is shown in Figure 2.

Figure 2 – Scale Types Classification

The definitions of the individual types can be found in Table 10.

Table 10 – Overview of scale types

|

Term |

Definition |

|

Automatic Filling Scale |

Instrument which fills containers with predetermined and virtually constant mass of product from bulk by automatic weighing, and which comprises essentially automatic feeding device(s) associated with weighing unit(s) and the appropriate control and discharge devices. (Definition is based on OIML R61) |

|

Catchweighing Scale (catchweigher) |

Automatic weighing instrument that weighs pre-assembled discrete loads or single loads of loose material. (Definition is based on OIML OIML R51) |

|

Automatic Weight Labeling Scale |

catchweigher that labels individual pre-assembled discrete loads (e.g. prepackages) with the weight value. (Definition is based on OIML OIML R51) |

|

Automatic Price Labeling Scale |

catchweigher that calculates the price to pay on the basis of the indicated mass and the unit price and labels individual pre-assembled discrete loads (e.g. prepackages with the weight value, unit price and price to pay). (Definition is based on OIML OIML R51) |

|

checkweigher |

catchweigher that sub-divides prepackages of different mass into two or more sub-groups according to the value of the difference between their mass and the nominal set point. (Definition is based on OIML OIML R51) |

|

Continuous Scale |

An automatic weighing instrument for continuously weighing a bulk product on a conveyor belt, without systematic subdivision of the mass and without interrupting the movement of the conveyor belt. (Definition is based on OIML OIML R50) |

|

Loss In Weight Scale |

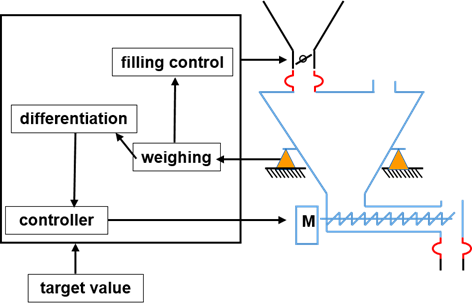

A special type of continuous scale is the loss in weight scale. It works according to the principle of controlled material increase or removal. The weight of the material is weighed by load cells and the change in weight per time unit is determined. The change in weight corresponds to the actual feed rate of the feeder when filling or emptying is stopped. A schematic overview is shown in Figure 3. |

|

Piece Counting Scale |

A scale that can determine the number of parts in the load. A reference weight must first be determined or stored. |

|

Recipe Weighing Scale |

Scale with the capacity to manage and process recipes. Single recipe steps in a recipe can be the weighing of ingredients, the display of user instructions, the monitoring of switching values or the activation of aggregates. |

|

Simple Scale |

Simple scales do not have any major functional extensions and provide only basic weighing functionality, i.e. acting as a sensor. |

|

Hopper Scale |

A scale for weighing a bulk product with a tank, box or hopper mounted on one or more weighing bridges. The primary use case is tank level monitoring.

|

|

Laboratory Scale |

The laboratory scales have a particularly high resolution and represent highly sensitive measuring insturments. For this reason, additional processes and measures are necessary in order to carry out an accurate measurement. For this purpose, e.g. the shielding of the environment with additional signs may be necessary. |

|

Totalizing Hopper Scale

|

An automatic weighing instrument that weighs a bulk product by dividing it into discrete loads, determining the mass of each discrete load in sequence, summing the weighing results and delivering the discrete loads to bulk. (Definition is based on OIML OIML R107) |

|

Vehicle Scale |

Automatic or non-automatic scale having one or more weight bridges that determines the mass of a vehicle. The vehicle is typically a truck with or without a trailer or a rail wagon. A special variant is the automatic rail-weighbridge (see OIML R106), which has one or more load receptors, including rails for the transport of rail vehicles, which determine the mass of the wagons and/or of the entire train by weighing during travel. |