When the ANSI/ISA–88.01–1995: standard was applied to applications across a plant, there was a need to align the terminologies, models and key definitions between different process types: continuous, batch, and discrete processes. Discrete processes involve machines found in the packaging, converting, and material handling applications. The operation of these machines is typically defined by the OEM, system integrator, end user, or is industry specific.

OMAC (Organization for Machine Automation and Control) created a task group with members from technology providers, OEMs, system integrators, and end users to generate the PackML guidelines as a method to show how the ANSI/ISA–88.01–1995: concepts could be extended into packaging machinery and other types of machines typically used in assembly lines, filling lines, and other production lines.

The purpose of PackML is to:

- Define a standard state-based model for automated machines.

- Identify definitions for common terminology.

- Explain to practitioners how to use state programming for automated machines.

- Provide references to actual implementation examples and templates from automation and control vendors.

- Identify a common tag structure for automated machines in order to:

- Provide for “connect & pack” functionality

- Provide functional interoperability and a consistent look and feel across the plant floor.

- Provide consistent tag structure for connection to plant MES and enterprise systems.

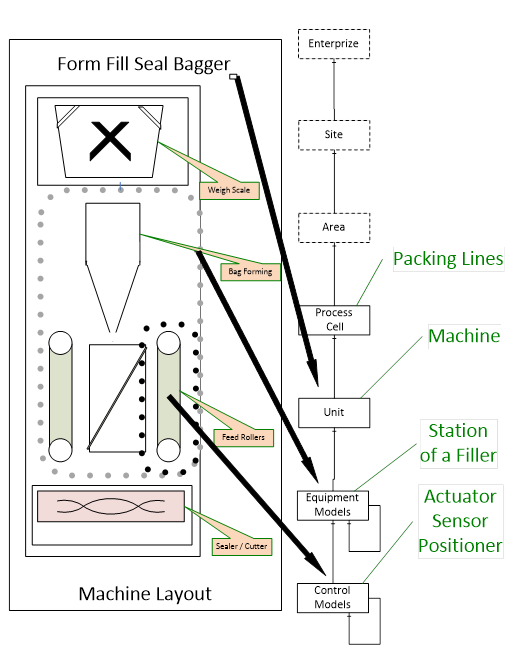

If automated machinery is modelled in an ANSI/ISA–88.01–1995: physical hierarchy, the example mapping shown in Figure 1 is possible, from ISA-TR88.00.02-2015. The example in this document will assume that a machine can represent the unit level in the ISA88 hierarchy.

Figure 1 – Automated Machines using the ISA 88 Models

In the figure, the OPC UA interface and the PackML model might exist at the machine level. The communication and interactions below this level are machine specific. Some machines might have multiple Units which communicate using OPC UA / PackML, but they might also only expose the Machine using the OPC UA PackML interface to other Machines in packaging line or to the Packaging line controller.