Details of the PROFINET diagnosis concepts are contained in [PN Diag]. The main ideas are summarized in this chapter:

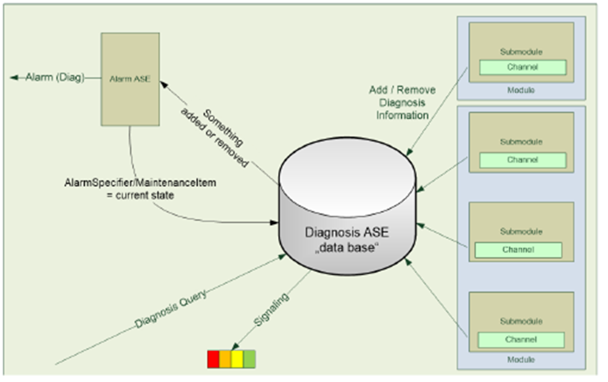

Figure 13 – Diagnosis base model from [PN Diag]

Each IO device maintains a global list of active diagnosis in a database called Diagnosis ASE.

All diagnosis entries are related to a channel of a submodule. The channel can represent a connected sensor or actor as well as the whole submodule. Submodule related diagnosis is marked with the channel number 0x8000.

If some relevant diagnosis or maintenance appears or disappears on a channel, an entry in the diagnosis ASE is added or removed. In this case, the IO controller is informed with diagnosis alarm to have event driven diagnosis information available in the PLC.

A supervisor like an Edge gateway or diagnosis tool can query the diagnosis ASE with a defined PROFINET record. If the ASE contains entries, the query is answered with a list of diagnosis entries. Otherwise the answer is empty to reduce the network load.

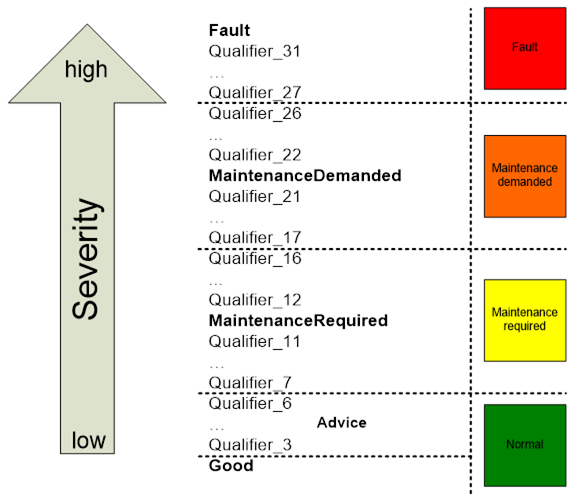

Figure 14 – Severity classification of diagnosis from [PN Diag]

Each channel diagnosis entry contains a severity and a combination of error codes (see Figure 14). Some of these codes are system defined and can be decoded with the help of a general XML file available via PI. Vendor specific and profile specific error codes can be contained in the GSD file of the device.