The DriveAxisType ObjectType contains the Variables and Properties common for all Axis Objects. This ObjectType is specified as abstract and cannot be used directly.

Table 14 – DriveAxisType Definition

|

Attribute |

Value |

||||

|

BrowseName |

DriveAxisType |

||||

|

IsAbstract |

True |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the 0:BaseObjectType defined in OPC 10000-5. |

|||||

|

0:HasProperty |

Variable |

ApplicationTag |

0:String |

0:PropertyType |

O, RO |

|

0:HasComponent |

Method |

SetApplicationTag |

|

|

O |

|

0:HasComponent |

Object |

Lock |

|

2:LockingServicesType |

O |

|

0:HasProperty |

Variable |

AxisType |

0:Byte |

AxisTypeVariableType |

M, RO |

|

0:HasComponent |

Object |

Monitoring |

|

0:FolderType |

M |

|

0:HasComponent |

Object |

PNSignals |

|

0:FolderType |

O |

|

0:HasComponent |

Object |

LimitSupervision |

|

0:FolderType |

O |

|

0:HasComponent |

Object |

Safety |

|

SafetyType |

O |

|

0:HasComponent |

Object |

CharacteristicsConverter |

|

0:FolderType |

M |

|

0:HasComponent |

Object |

CharacteristicsMotorAndControl |

|

0:FolderType |

O |

|

0:HasComponent |

Object |

VelocityProfile |

|

0:FolderType |

M |

|

0:HasComponent |

Object |

Maintenance |

|

0:FolderType |

M |

|

0:GeneratesEvent |

ObjectType |

DiagnosisAlarmType |

|

|

|

|

0:HasComponent |

Object |

Logbook |

|

3:LogbookType |

O |

|

Conformance Units |

|||||

|

PDRV Measurement |

|||||

|

PDRV Diagnosis Events |

|||||

|

PDRV Signals |

|||||

General Properties

The ApplicationTag Variable contains information given by the overall application. The purpose is to provide additional semantic information about the represented Axis/DO role or labelling in the context of the specific overall application context (machine, site or plant). Therefore, plant operators and/or application engineers are responsible to set the content of the ApplicationTag with information used for site management, asset management or other administrative purposes, e.g. “Production Line <m>/Machine <n>/x-Axis”. Furthermore, information like “tag-function” out of the PROFINET I&M-1 record or the “descriptor” out of the I&M-3 record may be used as content of the ApplicationTag Variable.

However, as a default, vendors might generate the ApplicationTag string out of the PROFINET device structure given by standard PROFINET configuration data as initial content of the Variable. The generic default string is “<NameOfStation >/Drive Axis Nr. <axis number>”, where the <NameOfStation > is the NameOfStation of the PROFINET Drive device and the <axis number> is the PROFINET device module number representing the related PROFIdrive axis DO.

The Client can change the Value of this Variable by invoking the SetApplicationTag Method.

Before invoking a Method of the DriveAxisType Object, Clients must gain exclusive write access (“lock” the DriveAxisType Object) using the Lock Object.

The Lock Object ensures exclusive Method call for one Client. The Client locks the DriveAxisType Object by invoking the InitLock Method of the Lock Object. The Client invokes ExitLock to release the lock. The scope of the lock comprises all components of the DriveAxisType Object.

SetApplicationTag Method

This Method sets the Value of the ApplicationTag Variable. The security constraints defined in chapter 6.2 apply.

Signature

SetApplicationTag (

[in] 0:String ApplicationTag

);

|

Argument |

Description |

|

ApplicationTag |

String containing the desired content of the ApplicationTag Variable. |

The Method Result Codes (defined in Call Service) are defined in Table 15.

Table 15 – Possible Method Result Codes

|

Result Code |

Description |

|

Good |

The Method execution was successful. |

|

Bad_UserAccessDenied |

The user has not the authorization to execute the Method. |

|

Bad_InvalidArgument |

The Server is not able to apply the name. The ApplicationTag string may be too long or may contain invalid characters. The Server may also reject duplicates. |

|

Bad_Locked |

The DriveAxisType Object is locked by a different Client’s Session. |

|

Bad_RequiresLock |

The DriveAxisType Object is not locked. Clients must lock the DriveAxisType Object before invoking a Method. |

|

Bad_UnexpectedError |

The Server is not able to execute the function because an unexpected error occurred. The Device might be temporarily unavailable or unreachable due to network failure. |

The AxisType Property contains the mechanical drive type of the represented Axis/DO modelled as AxisTypeVariableType (see 9.1).

The Value shall be 0 (reference “LINEAR_MOTION”) for linear axis drives and 1 (reference “ROTATORY_MOTION”) for rotatory axis drives.

Some components of the DriveAxisType have additional subcomponents which are defined in Table 16. For detailed descriptions of the Variables see Table 33.

Table 16 – DriveAxisType additional Subcomponents

|

BrowsePath |

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

||

|

PNSignals |

0:HasComponent |

Variable |

<SignalName> |

0:Number |

0:BaseDataVariableType |

MP, RO |

||

|

0:HasProperty |

Variable |

SignalNumber |

0:UInt16 |

0:PropertyType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

AxisState |

0:UInt16 |

0:MultiStateDiscreteType |

M, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

ControlPriority |

0:UInt16 |

0:MultiStateDiscreteType |

M, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

ControlMode |

0:UInt16 |

0:MultiStateDiscreteType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

OutputCurrent |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

Torque |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

Force |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

Power |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

MotorTemperature |

0:Float |

TemperatureVariableType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

ConverterTemperature |

0:Float |

TemperatureVariableType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

DeviceTemperature |

0:Float |

TemperatureVariableType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

FeedbackSensor1Temperature |

0:Float |

TemperatureVariableType |

O, RO |

||

|

Monitoring |

0:HasComponent

|

Variable |

FeedbackSensor2Temperature |

0:Float |

TemperatureVariableType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

FeedbackSensor3Temperature |

0:Float |

TemperatureVariableType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

BrakeResistorTemperature |

0:Float |

TemperatureVariableType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

DcBusVoltage |

0:UInt16 |

0:AnalogUnitType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

PositionFollowingError |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

VelocityFollowingError |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

Monitoring |

0:HasComponent |

Variable |

BrakeStatus |

0:Byte |

0:MultiStateDiscreteType |

O, RO |

||

|

Applied from 2:IOperationCounterType Interface: |

||||||||

|

Maintenance |

0:HasProperty |

Variable |

2:PowerOnDuration |

0:Duration |

0:PropertyType |

O, RO |

||

|

Maintenance |

0:HasProperty |

Variable |

2:OperationDuration |

0:Duration |

0:PropertyType |

O, RO |

||

|

Maintenance |

0:HasProperty |

Variable |

2:OperationCycleCounter |

0:UInteger |

0:PropertyType |

O, RO |

||

|

|

||||||||

|

Maintenance |

0:HasComponent |

Variable |

MotorCapacityUtilization |

0:UInt16 |

0:BaseDataVariableType |

O, RO |

||

|

Maintenance |

0:HasComponent |

Variable |

ConverterCapacityUtilization |

0:UInt16 |

0:BaseDataVariableType |

O, RO |

||

|

CharacteristicsConverter |

0:HasComponent |

Variable |

InputConverterAcInputVoltage |

0:UInt16 |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsConverter |

0:HasComponent |

Variable |

OutputConverterPulseFrequency |

0:UInt16 |

0:AnalogUnitType |

M, RO |

||

|

CharacteristicsConverter |

0:HasComponent |

Variable |

IntermediateCircuitVoltageConfigured |

0:UInt16 |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsConverter |

0:HasComponent |

Variable |

ConverterThermalLoadLimitConfigured |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsConverter |

0:HasComponent |

Variable |

ConverterExcessCurrentConfigured |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsConverter |

0:HasComponent |

Variable |

BrakeResistorExcessCurrentLimit |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

PowerRated |

0:Float |

0:AnalogUnitType |

M, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

SpeedRated |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

TorqueRated |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

ForceRated |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

MaxCurrent |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasProperty |

Variable |

UfRatio |

0:Float |

0:PropertyType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

RunUpVoltage |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

DcBrakingCurrent |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

DcBrakingTime |

0:UInt16 |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

FeedbackMode |

0:UInt16 |

0:MultiStateDiscreteType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

SpeedMaxConfigured |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

TorqueMaxConfigured |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

MotorThermalLoadLimitConfigured |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

MotorExcessCurrentConfigured |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

MotorType |

0:Byte |

0:MultiStateDiscreteType |

M, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

PositionFollowingErrorLimit |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

CharacteristicsMotorAndControl |

0:HasComponent |

Variable |

VelocityFollowingErrorLimit |

0:Float |

0:AnalogUnitType |

O, RO |

||

|

VelocityProfile |

0:HasComponent |

Variable |

RfgRampDownTime |

0:Float |

0:BaseAnalogType |

M, RO |

||

|

VelocityProfile |

0:HasComponent |

Variable |

QuickStopRampDownTime |

0:Float |

0:BaseAnalogType |

M, RO |

||

|

VelocityProfile |

0:HasComponent |

Variable |

NominalSpeed |

0:Float |

0:BaseAnalogType |

M, RO |

||

|

VelocityProfile |

0:HasComponent |

Variable |

RampDeceleration |

0:Float |

0:AnalogUnitType |

M, RO |

||

|

VelocityProfile |

0:HasComponent |

Variable |

QuickStopRampDeceleration |

0:Float |

0:AnalogUnitType |

M, RO |

||

The child Nodes of the DriveAxisType have additional Attribute values defined in Table 17.

Table 17 – DriveAxisType Attribute values for child Nodes

|

BrowsePath |

Value Attribute |

|||

|

S1_SWITCHING_ON_INHIBITED S2_READY_FOR_SWITCHING_ON S3_SWITCHED_ON S4_OPERATION S51_RAMP_STOP S52_QUICK_STOP S41_POS_BASIC_STATE S42_POS_JOGGING S43_POS_BRAKING_WITH_RAMP S44_POS_HOMING_PROCEDURE S451_POS_TRAVERSING_TASK_ACTIVE S452_POS_BRAKING_WITH_RAMP S453_POS_INTERMEDIATE_STOP |

|||

|

NONE PROFIBUS_PRIORITY PROFIBUS_CONTROL PROFINET_PRIORITY PROFINET_CONTROL LOCAL_CONTROL SETUP_TOOL_CONTROL |

|||

|

TORQUE_CONTROL FORCE_CONTROL SPEED_CONTROL SPEED_CONTROL_DSC POSITION_CONTROL |

|||

|

FEEDBACK_SENSOR_1 FEEDBACK_SENSOR_2 FEEDBACK_SENSOR_3 SENSORLESS |

|||

|

PM_SYNCHRONOUS_ROTARY PM_SYNCHRONOUS_LINEAR STEPPER_ROTARY STEPPER_LINEAR INDUCTION_ROTATORY INDUCTION_LINEAR HYDRAULIC_MOTOR_ROTARY HYDRAULIC_CYLINDER_LINEAR PNEUMATIC_MOTOR_ROTARY PNEUMATIC_CYLINDER_LINEAR |

PNSignals folder in Signals sub-aspect

The PNSignals folder contains Signal Variables representing the Signals as defined in [PI 3172 PDP], chapter 6.3.4.2, Table 86. The supported Standard Signals are determined by the configured Standard Telegram modular telegram configuration and may also be freely configured (see [PI 3172 PDP], chapter 6.3.4.4). The Axis/DO IO Data configuration may also contain profile- or vendor-specific Signals with signal No. 100 and greater.

The Server shall provide as many <SignalName> Variables as are needed to represent the configured Signals. The placeholder template string shall be replaced with the Signal’s abbreviation as specified in [PI 3172 PDP], Table 86. For profile- and vendor specific Signals the abbreviations specified by the profile or vendor apply. For vendor specific Signals, the SignalNumber Property shall always be provided for the representing Signal Variable.

The DataType provided for the Signal Variables shall be provided according to the length of the Signal as specified in [PI 3172 PDP], chapter 6.3.4.2, Table 86: For 16-bit Signals, the DataType shall be 0:UInt16. For 32-bit Signals, the DataType shall be 0:UInt32. For Signals with sign, the corresponding signed DataTypes 0:Int16 and 0:Int32 shall be provided.

Monitoring folder in Actual and Command Values sub-aspect

The Monitoring folder contains Monitoring Variables describing measurements of the Axis/DO which are of interest for monitoring (see derived Axis/DO ObjectTypes and Table 33) encoded as numeric data type. If the corresponding Standard Signal is configured and its representation is provided in the PNSignals folder, the Monitoring Variable shall be linked to the Signal Variable using a 0:RepresentsSameEntityAs ReferenceType.

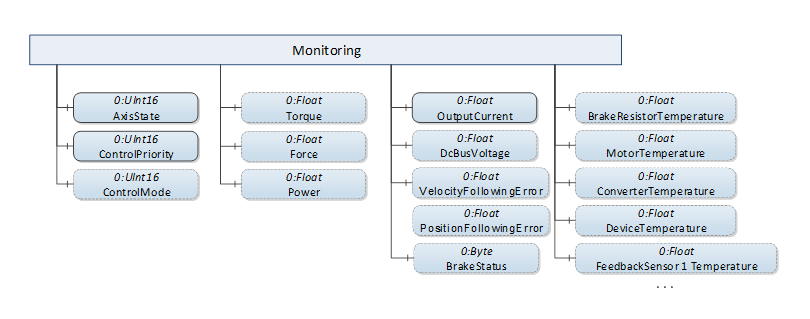

Figure 13 Shows the possible components of the “Monitoring” folder common for all derived Axis Object types, as described in Table 16.

Figure 13 – Monitoring folder components

The AxisState Variable contains the actual state of the Axis/DO internal state machine modelled as 0:MultiStateDiscreteType defined in [OPC 10000-8].

The ControlPriority Variable contains the leading control context (PROFIBUS, PROFINET, setup tool, …) of the Axis/DO also modelled as 0:MultiStateDiscreteType.

The ControlMode Variable contains the currently active control function in the overall control cascade modelled as 0:MultiStateDiscreteType.

The content of the EnumStrings lookup table Property is defined in Table 17 for all these 0:MultiStateDiscreteType Variables. The “Locale” field of the 0:LocalizedText structures is Server specific.

For a description of all Variables and Properties in the “Monitoring” folder see Table 33.

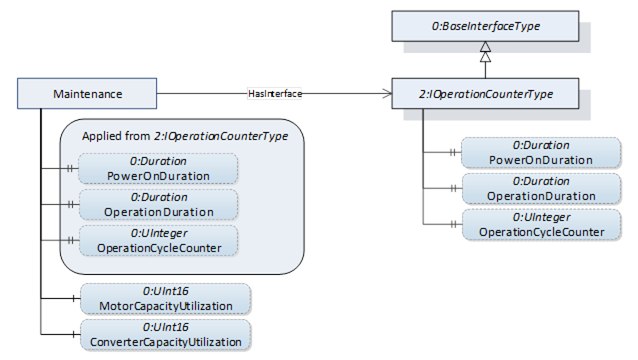

Maintenance folder in Axis Properties sub-aspect

The Maintenance folder contains optional properties defined by the 2:IOperationCounterType Interface specified in [OPC 10000-100] as well as parameters yielding capacity related information. Figure 14 shows the possible components of the “Maintenance” folder common for all derived Axis Object types, as described in Table 16.

Figure 14 – Maintenance folder components

For a description of the Variables and Properties in the “Maintenance” folder see Table 33.

LimitSupervision folder in Axis Properties sub-aspect

The LimitSupervision folder contains Variables with Values describing limit values for motor current, torque, and the like. These limit Variables differ between concrete derived Axis ObjectTypes and are specified separately for each derived Axis ObjectType.

For a description of the Variables in the “LimitSupervision” folder see Table 33.

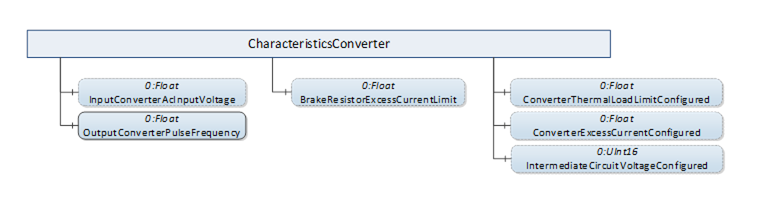

CharacteristicsConverter folder in Axis Properties sub-aspect

The CharacteristicsConverter folder contains Variables with Values describing key data of the Drive’s converter. Figure 15 shows the possible components of the “CharacteristicsConverter” folder common for all derived Axis Object types, as described in Table 16.

Figure 15 – CharacteristicsConverter folder components

For a description of the Variables in the “CharacteristicsConverter” folder see Table 33.

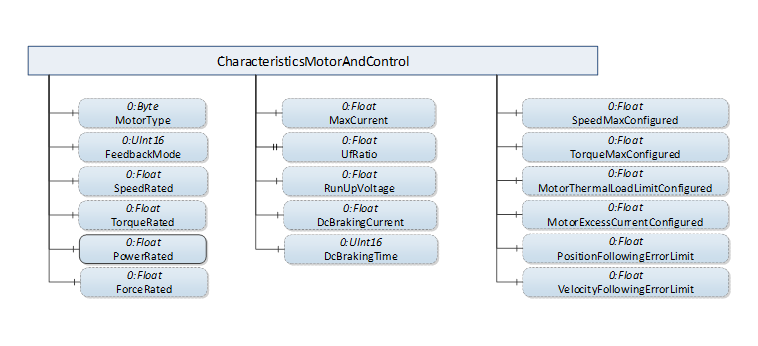

CharacteristicsMotorAndControl folder in Axis Properties sub-aspect

The CharacteristicsMotorAndControl folder contains Variables with Values describing key data of the Drive’s motor and its key control features. Figure 16 shows the possible components of the “CharacteristicsMotorAndControl” folder common for all derived Axis Object types, as described in Table 16.

Figure 16 – CharacteristicsMotorAndControl folder components

The FeedbackMode Variable shall contain the Value “FEEDBACK_SENSOR_1” if only one sensing device is present, which is the motor sensor in this case.

For a description of the Variables in the “CharacteristicsMotorAndControl” folder see Table 33.

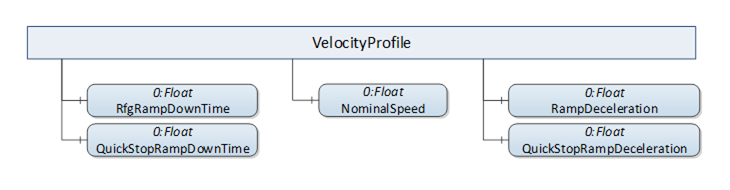

VelocityProfile folder in Axis Properties sub-aspect

The VelocityProfile folder contains Variables describing key properties of brake ramps. The folder contains the properties mandatory for each derived Axis Object types. Figure 17 shows the components of the “VelocityProfile” folder common for all derived Axis Object types, as described in Table 16.

Figure 17 – VelocityProfile folder components

Diagnosis sub-aspect

The 3:LogbookType Object defined in [OPC 30143 ENC] provides Methods for accessing the Drive’s fault buffer (see [PI 3172 PDP] Fault Buffer Mechanism). These Methods can be used by Clients to obtain the active diagnosis entries (that is, get all fault entries without “Event going” timestamp) or apply custom filter criteria (see [OPC 30143 ENC] chapter 7.5 LogbookType for details). In conjunction with establishing a Subscription for one of the supported EventTypes of the 3:LogbookType Object Clients can synchronize themselves with the current diagnosis status and will receive Notifications for each change of the diagnosis status subsequently, such as coming, going and the like. The possible values for the EventCode are defined in [PI 3172 PDP], see Table 57.

The Server might provide DiagnosisAlarmType Events and / or 3:LogbookEventType Events.

Safety Object in Actual and Command Values sub-aspect

The optional SafetyType Object has SafetyFunctionType Object components describing safety functions. For each available safety function, basic settings regarding selection and activation status are provided (see 7.8 and 7.9).