This specification was created by a joint working group of the OPC Foundation and PLCopen. It defines a set of IEC 61131-3 based function blocks for mapping the OPC UA Client functionalities. With this functionality implemented on a controller it becomes possible to initiate a communication session to any other available OPC UA Server.

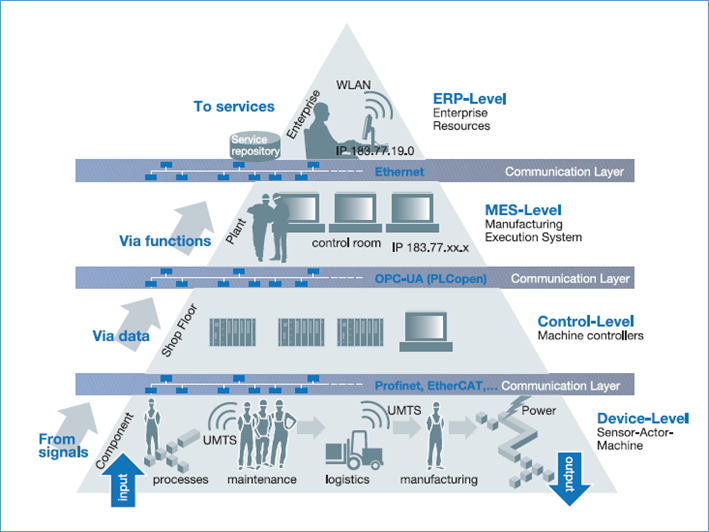

The interaction between IT and the world of automation is certainly not revolutionary, but corresponds with the established model of the automation pyramid:

This model is fundamentally based on the assumption that, in terms of communication, a controller as a main component of the automation system is “dumb”, and always merely responds to requests “from above”. The higher level is always the client and initiates data requests – the lower layer is always the server and courteously responds. In the modern world the strict separation of levels and the top-down approach of the information flow soften and mix. In a smart network, every device or service must be able to initiate independent communication with all other services.

This document is about OPC-UA client functionality out of the IEC 61131-3 controller: A controller can exchange complex data structures horizontally with other controllers independently from fieldbus system or vertically with other devices using an OPC-UA server call in an MES/ERP system in order to collect data or write new production orders to the cloud. It allows a production line to be independently active in combination with integrated OPC UA Security features.

OPC-UA client functionality in a controller does not provide hard deterministic real time and so it’s not a deterministic fieldbus – but UA provides fast, secured communication providing modelling mechanism for information models.

Note: The FUNCTION BLOCKS are based on the second Edition of IEC 61131-3.

The OPC Foundation defines standards for online data exchange between automation systems. They address access to current data (OPC DA), alarms and events (OPC A&E) and historical data (OPC HDA). Those standards are successfully applied in industrial automation.

The new OPC Unified Architecture (OPC-UA) unifies the existing standards and brings them to state-of-the-art technology using service-oriented architecture (SOA). Platform-independent technology allows the deployment of OPC-UA beyond current OPC applications only running on Windows-based PC systems. OPC-UA can also run on embedded systems as well as Linux / UNIX based enterprise systems. The provided information can be generically modelled and therefore arbitrary information models can be provided using OPC-UA.

PLCopen, as an organization active in industrial control, is creating a higher efficiency in your application software development: in one-off projects as well as in higher volume products. As such it is based on standard available tools to which extensions are and will be defined.

With results like Motion Control Library, Safety, XML specification, Reusability Level and Conformity Level, PLCopen made solid contributions to the community, extending the hardware independence from the software code, as well as reusability of the code and coupling to external software tools. One of the core activities of PLCopen is focused around IEC 61131-3, the only global standard for industrial control programming. It harmonizes the way people design and operate industrial controls by standardizing the programming interface. This allows people with different backgrounds and skills to create different elements of a program during different stages of the software lifecycle: specification, design, implementation, testing, installation and maintenance. Yet all pieces adhere to a common structure and work together harmoniously.