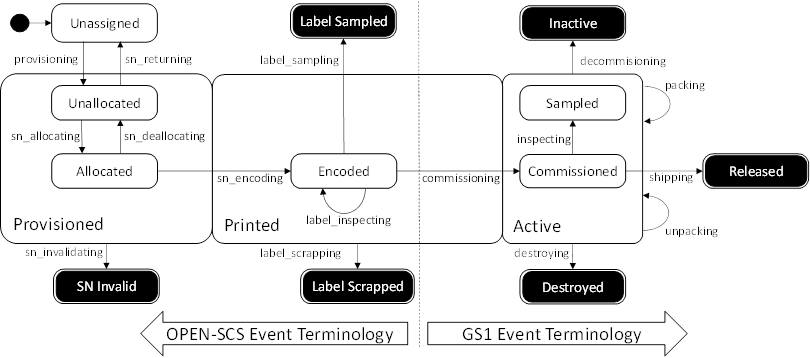

The state and event model for a Serial Number shall follow the model displayed in Figure 4.

Note 1The state is managed is a distributed manner, no single system provides the state of the serial numbers. The events and methods defined in this document provide the means for applications to manage their internal state representation.

Note 2All Serial Numbers in a Serial Number Collection only contain Serial Numbers with the same state.

Note 3All Serial Numbers in a Label Collection only contain Serial Numbers with the same state and ancillary information.

Note 4Generally the events that record a transition can come from any state or substate.

Figure 4 – Serial Number State and Event Model

Each Serial Number state is defined in Table 1.

Table 1 – Serial Number State Definitions

|

SID State |

Description |

Examples |

|

Unassigned |

The Serial Number has not been assigned to production or a packaging run. The unassigned state is used for communication to systems that assign serial numbers. |

A request is sent to an agent or serial number management system that creates serial numbers, along with possible information such as product codes. |

|

Unallocated |

As Serial Number has been assigned to production or a packaging run, but it has not yet been allocated for use a specific production run of a product or aggregation. |

A local serial number management system maintains a set of unallocated serial numbers. |

|

Allocated |

The Serial Number has been assigned to a specific product or aggregation production run. |

Serial Numbers are available and maintained in a local printer for printing on a label. |

|

SN Invalid |

The Serial Number is no longer viable, and the related serial number is no longer defined. The Serial Number will not be the subject of subsequent events. |

A process order using the Serial Numbers was cancelled, the provisioned Serial Number are not associated with a physical product and will not be further used. |

|

Encoded |

The Serial Number has been written to a barcode or RFID tag, but not yet commissioned. |

An industrial printer prints a label. |

|

Label Sampled |

The printed label has been retained and is not associated with a physical product or aggregation. |

A printed label is attached to a batch record. |

|

Label Scrapped |

A label was encoded with a Serial Number but was made unusable before being applied to a product or aggregation. |

A vision system detects that a label was misapplied or ripped on a product or aggregation and the label was removed from the product or aggregation. |

|

Commissioned |

The Serial Number has been associated with a physical product or aggregation but has not yet left the responsibility of production. The Serial Number can now be identified as a SID. |

A label is attached to a package, and the package is being placed into a case, and the case is being placed on a pallet. |

|

Sampled |

The product or aggregation is to be used as a sample for testing or other use, not to be made active. |

Product was pulled from the end of the packaging line and stored in a facility for later stability testing. |

|

Inactive |

The product or aggregation is no longer active but may not have been destroyed. GS1 defines this disposition as a decommissioned object that may be reintroduced to the supply chain, however any status change after decommissioning is not in scope of the PSS. |

Product over its expiration date is send to a facility for destruction or for testing to determine its viability. |

|

Destroyed |

The product or aggregation has been fully rendered non-usable. |

A production error was detected, and all packaged product was pulled from the line and destroyed. |

|

Released |

The Serial Number has been associated with a physical product or aggregation and has left the responsibility of production. |

A pallet of products/packages is delivered to the warehouse and the transfer of control is sent to the ERP system. |

Each Serial Number event is defined in Table 2. The events occur as a result of a business or process step.

Table 2 – Serial Number Events

|

Event |

Description |

|

provisioning |

Unassigned Serial Numbers were made available for use in eventual encoding and commissioning. |

|

sn_returning |

Unallocated Serial Numbers may be returned to the Unassigned state |

|

sn_allocating |

Unallocated Serial Numbers are to be assigned for use in a packaging run |

|

sn_deallocating |

Unused allocated Serial Numbers may be returned to the unallocated state. |

|

sn_invalidating |

Provisioned Serial Numbers are no longer available for use |

|

sn_encoding |

Serial Numbers and other associated information are written to a barcode or RFID tag but are not yet associated with a product or aggregation. (Derived from the GS1 “encoding” business step.) |

|

label_inspecting |

Written barcode or RFID was read to address potential physical or documentation defects. |

|

label_sampling |

Written barcode or RFID is pulled from production and retained as a sample for later testing or inspection. |

|

label_scrapping |

Written barcode or RFID was made unusable in production and the serial number if no longer associated with a packaging run |

|

commissioning |

A Serial Numbers is associated with a specific product or aggregation. (Derived from the GS1 “commissioning” business step.) |

|

inspecting |

Product or aggregation is pulled from production and retained as a sample for later testing or inspection. |

|

shipping |

Indicates the overall process of staging, outbound, loading and departing the responsibility of production. (Derived from the GS1 “shipping” business step.) |

|

decommissioning |

Process of disassociating an instance-level identifier (Serial Number) with an object. For example, either time or an event has caused to the serial number to be disassociated with a product or aggregation. (Derived from the GS1 “decommissioning” business step.) |

|

destroying |

Process of terminating a physical object. For an instance-level identifier, the object will not be the subject of subsequent events; subsequent events are likely indicative of error (such as a stray read of a tag inside an incinerator). (Derived from the GS1 “destroying” business step.) |

|

packing |

Denotes a specific activity within a business process that includes putting objects into a larger container. For example, adding labeled bottles into a case or adding cases into a pallet. (Derived from the GS1 “packing” business step.) |

|

unpacking |

Denotes a specific activity within a business process that includes removing products (individuals, inners, cases, pallets) from a larger container. For example, removing labeled bottles from a case or removing cases from a pallet. (Derived from the GS1 “unpacking” business step.) |