The EquipmentType is used to structure elements for machine equipment.

The EquipmentType is formally defined in Table 56.

Table 56 – EquipmentType Definition

|

Attribute |

Value |

||||

|

BrowseName |

EquipmentType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the 0:BaseObjectType defined in OPC 10000-5 i.e. inheriting the InstanceDeclarations of that Node. |

|||||

|

0:HasComponent |

Object |

Tools |

|

ToolListType |

O |

|

Conformance Units |

|||||

|

MachineTool MachineToolType Mandatory Nodes |

|||||

|

MachineTool Equipment ToolIdentification |

|||||

Tools is the entry point to the list of BaseToolType subtype instances in the machine. The list of tools provided here shall contain the tools that are present in the machine and the magazines the machine has automated access to.

The ToolListType is a list of tools, where a tool may be a single tool or a multitool.

The ToolListType is formally defined in Table 57.

Table 57 – ToolListType Definition

|

Attribute |

Value |

||||

|

BrowseName |

ToolListType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the 0:BaseObjectType defined in OPC 10000-5 i.e. inheriting the InstanceDeclarations of that Node. |

|||||

|

0:HasComponent |

Object |

<Tool> |

|

BaseToolType |

OP |

|

0:HasProperty |

Variable |

0:NodeVersion |

0:String |

0:PropertyType |

O, RO |

|

0:GeneratesEvent |

ObjectType |

0:GeneralModelChangeEventType |

|

|

|

|

Conformance Units |

|||||

|

MachineTool Equipment ToolIdentification |

|||||

|

MachineTool Equipment Dynamic Tool List |

|||||

<Tool > is an OptionalPlaceholder for nodes of BaseToolType. The tool list can thus contain any number of tools, including none. For the DisplayName of the <Tool >, it is recommended to use the value of the Name Property of the respective BaseToolType instance.

The contents of the ToolListType instance can change during the Server runtime (e.g. if tools are inserted into the machine or removed from it). A change in the list can be indicated using the NodeVersion Property and the GeneralModelChangeEventType. The NodeVersion and the GeneralModelChangeEventType are intended to be used in the way defined in OPC 10000-3 and 7.3.

The BaseToolType serves as a supertype to the ToolType and the MultiToolType. It is an abstract type, meaning it is not instantiated, only the subtypes are.

The BaseToolType is formally defined in Table 58.

Table 58 – BaseToolType Definition

|

Attribute |

Value |

|||||

|

BrowseName |

BaseToolType |

|||||

|

IsAbstract |

True |

|||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

|

Subtype of the 0:BaseObjectType defined in OPC 10000-5 i.e. inheriting the InstanceDeclarations of that Node. |

||||||

|

0:HasProperty |

Variable |

Identifier |

0:String |

0:PropertyType |

O, RO |

|

|

0:HasComponent |

Object |

Location |

|

0:BaseObjectType |

O |

|

|

0:HasProperty |

Variable |

Name |

0:String |

0:PropertyType |

O, RO |

|

|

Conformance Units |

||||||

|

MachineTool Equipment ToolIdentification |

||||||

|

MachineTool Equipment Dynamic Tool List |

||||||

Table 59 – BaseToolType Additional Subcomponents

|

BrowsePath |

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

|

Location |

0:HasProperty |

Variable |

Name |

0:String |

0:PropertyType |

M, RO |

|

Location |

0:HasProperty |

Variable |

PlaceNumber |

0:UInt16 |

0:PropertyType |

M, RO |

Identifier is a unique identifier for a tool. The Identifier can be used to provide a unique ID given by a superordinated management system. This ID can’t be generated on the machine, it has to be transferred to the machine by a global tool management system.

The Location indicates where the tool is located, represented by Name, a name for the tool’s location (e.g. the tool magazine) and PlaceNumber, the place number at this location (refer to Table 59). If there is a shared magazine for multiple machines, a tool will be shown in the tool list (see 8.5.1 and 8.5.2) of all machines for which the tool is available.

The Name is used to name a tool to ease recognition. This name can be specific to the tool (e.g. “special_formpress_part294”), to the type of tool (e.g. “8mm drill”) or to the program (e.g. “T3”).

The ToolType is the representation of a tool. Tools are exchangeable components used in a machine to execute the production process and may for example be drills, ball milling heads, cutting inserts, pinching tools and so forth. It may also be a non-contact tool, for example a processing laser.

The ToolType is formally defined in Table 60.

Table 60 – ToolType Definition

|

Attribute |

Value |

||||

|

BrowseName |

ToolType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseToolType defined in 8.5.3 i.e. inheriting the InstanceDeclarations of that Node. |

|||||

|

0:HasComponent |

Variable |

ControlIdentifier1 |

0:UInt32 |

0:BaseDataVariableType |

M, RO |

|

0:HasComponent |

Variable |

ControlIdentifier2 |

0:UInt32 |

0:BaseDataVariableType |

O, RO |

|

0:HasComponent |

Variable |

ControlIdentifierInterpretation |

ToolManagement |

0:BaseDataVariableType |

M, RO |

|

0:HasComponent |

Variable |

LastUsage |

0:UtcTime |

0:BaseDataVariableType |

O, RO |

|

0:HasComponent |

Variable |

Locked |

0:Boolean |

0:BaseDataVariableType |

M, RO |

|

0:HasComponent |

Variable |

PlannedForOperating |

0:Boolean |

0:BaseDataVariableType |

O, RO |

|

0:HasComponent |

Object |

ToolLife |

|

0:BaseObjectType |

O |

|

Conformance Units |

|||||

|

MachineTool Equipment ToolIdentification |

|||||

|

MachineTool Equipment Dynamic Tool List |

|||||

|

MachineTool Equipment ToolLife |

|||||

The components of the ToolType have additional references which are defined in Table 61.

Table 61 – ToolType Additional Subcomponents

|

BrowsePath |

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

|

Locked |

0:HasProperty |

Variable |

ReasonForLocking |

ToolLocked |

0:PropertyType |

M, RO |

|

ToolLife |

0:HasComponent |

Variable |

<ToolLifeEntry> |

0:Number |

ToolLifeType |

MP, RO |

The two components ControlIdentifier1, ControlIdentifier2 are to be interpreted depending on ControlIdentifierInterpretation (refer to 12.10). This reflects the main methods which CNC-based tool management approaches use. In a ToolNumberBased approach, only ControlIdentifier1 is provided and sufficient to identify the tool. In a system with a ToolGroupBasedManagemet, tools are identified by a group and an indexing number inside this group, which are provided as ControlIdentifier1 and ControlIdentifier2 respectively. Should yet another approach be present in a given system, this is indicated by the ControlIdentifierInterpretation being reported as custom. It shall be noted that this identification data is used to identify the tool in the reference frame of the tool management system inside the machine. In many applications the machine control system uses these identifiers to handle multiple tools which are equivalent and present in the machine as spares. For an identification of the tool inside the NC program or globally, independent of the machine management view, the properties Name and Identifier are provided by the BaseToolType.

LastUsage is the time, were the specific tool was the active tool on a tool carrier for the last time, while the machine was operating in an automatic mode (e.g. for CNC controllers: in Mdi- or Automatic-mode).

The property Locked represents whether the tool was locked from use in processing. If True, the tool was locked. It has an additional property as seen in Table 61, ReasonForLocking. ReasonForLocking is defined in 12.9.

The component PlannedForOperating marks tools which the machine control can already mark as being needed for the running NC program or process when being True.

The ToolLife reports on how the tool use and tool life is being currently managed and how far the use of the tool has progressed. If more than one measurement is provided as <ToolLifeEntry >, they shall show the same value as if only one entry was provided, so they shall not be accumulated by a Client.

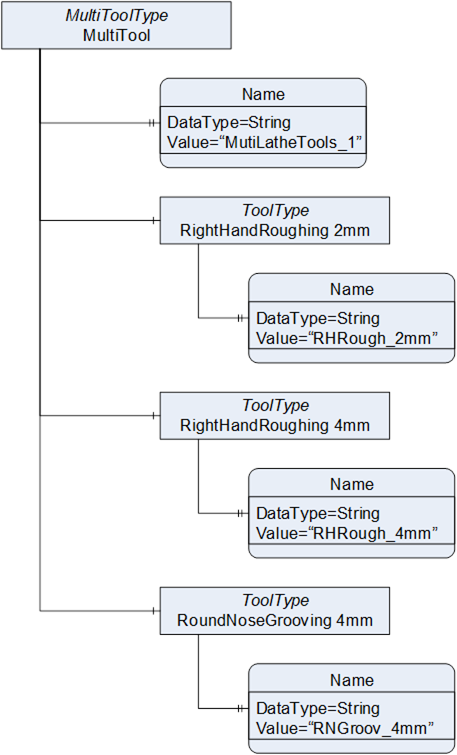

Figure 16 – Instance Example of a MultiToolType Object

The MultiToolType represents a unit of different tools, usually used in order to have several tools available in-process without requiring explicit tool-changes. Multitools carry several tools on one tool magazine socket or one revolver index position and will be mounted into the machine as one prepared unit.

Typical applications are in turning, when one indexed position of the tool revolver holds several outer-diameter cutting inserts and boring tools, such that a tool change process can quickly complete by merely readjusting the CNC setpoint position tool compensation.

An instance example on how to instantiate the MultiToolType is shown in Figure 16.

The MultiToolType is formally defined in Table 62.

Table 62 – MultiToolType Definition

|

Attribute |

Value |

||||

|

BrowseName |

MultiToolType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the BaseToolType defined in 8.5.3 i.e. inheriting the InstanceDeclarations of that Node. |

|||||

|

0:HasComponent |

Object |

<Tool> |

|

ToolType |

OP |

|

Conformance Units |

|||||

|

MachineTool Equipment ToolIdentification |

|||||

|

MachineTool Equipment Dynamic Tool List |

|||||

<Tool > is a placeholder for instances of ToolType. Using this placeholder, the individual ToolType instances making up the MultiTool can be represented in the information model. For individual tools within the MultiTool, use of the Location object is not recommended.