The Laboratory and Analytical Device Standard (LADS) Companion Specification provides a comprehensive framework for modelling and managing analytical and laboratory equipment. It does this by defining two primary views: the Hardware View and the Functional View.

The Hardware View focuses on the physical aspects of the devices and their components. This view is essential for various use cases related to asset management, including enhanced serviceability.

Key features of the Hardware View are introduced in the following subsections.

These are modelled with properties such as nameplates, installation dates, condition monitoring, and calibration & validation status.

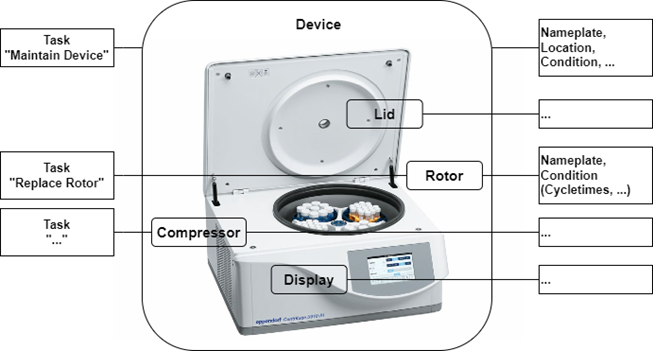

Hardware components like the Lid, Rotor, Drive, and Compressor are modelled in a sub-tree. Each component exposes its individual nameplate and maintenance-related information, similar to the device itself, and can also have components itself.

Recurrent tasks that affect either the entire device or individual components (such as inspection, maintenance, calibration, validation, cleaning, etc.) can be organized via LADS.

Figure 1 shows a centrifuge, including various components and the corresponding component data.

Figure 1 – Hardware View of a centrifuge

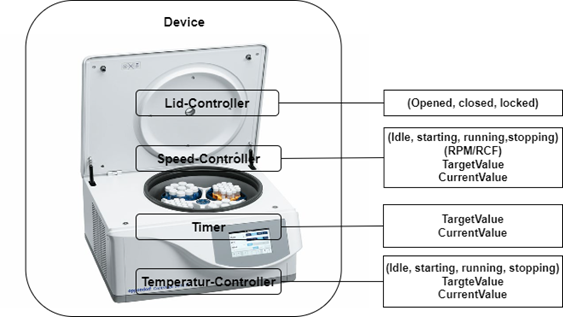

The Functional View deals with data relevant for the operation, automation, and orchestration of an instrument.

Key aspects of the Functional View are introduced in the following subsections.

Actions to achieve a specific outcome. (Typical functions include but are not limited to sensors, controllers, actuators, timers, etc. They may utilize one or more tangible components.)

The complete list of Functions can be found in section 7.4

Figure 2 shows a centrifuge, including various components and the corresponding component data.

Figure 2 – Function View of a centrifuge

Many laboratory and analytical devices allow the user to define and run programs, also called methods. The Program Manager organizes program templates, runs programs, and manages the result data generated during a run, providing device-level orchestration.

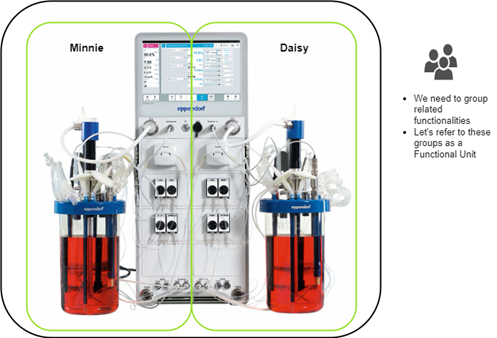

Functional Units are aggregations of functions designed to achieve a specific outcome. Typically, a Functional Unit is utilized by only one user at a time and exposes its current state. It may optionally include a Program Manager. A Functional Unit can be seen as a virtual device within a LADS Device, grouping together several (potentially redundant) functions. This concept is particularly useful when a LADS Device contains multiple functions that can be grouped as virtual devices or behave as separate devices. In such cases, a LADS Device can be divided into multiple Functional Units, with each Functional Unit representing a virtual device.

For instance, consider a bioreactor vessel with two separate interfaces (see Figure 3). Each container has its own functions, such as a temperature sensor and a motor, and its own program. This setup allows the bioreactor to be split into two Functional Units, each representing a separate container with its own program and set of functions.

Figure 3 – Example of a LADS Device with two Functional Units