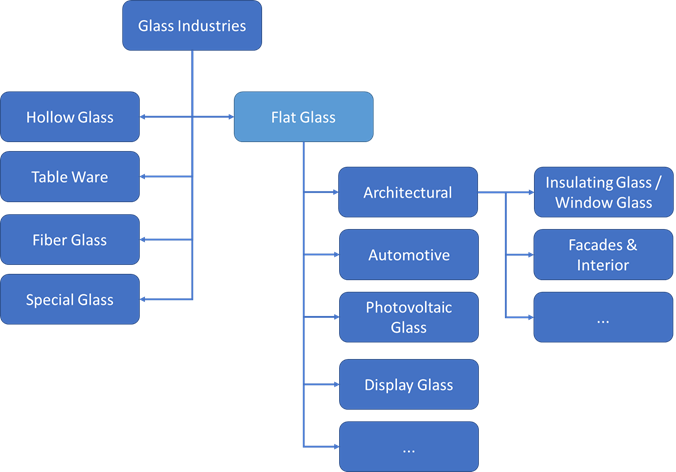

The glass industry is one of the base material industries that, on the one hand has a long tradition, and, on the other hand, is crucial for all modern applications. It ranges from, table ware, bottles for beverages and to perfume up to flat and bended glass for facades, windows, cars and technological applications such as for televisions and mobile devices. Figure 2 gives an overview of the glass domain. This specification only describes the flat glass domain. Other part will be defined OPC UA information models for other domains.

Figure 2 – Overview glass industries domains

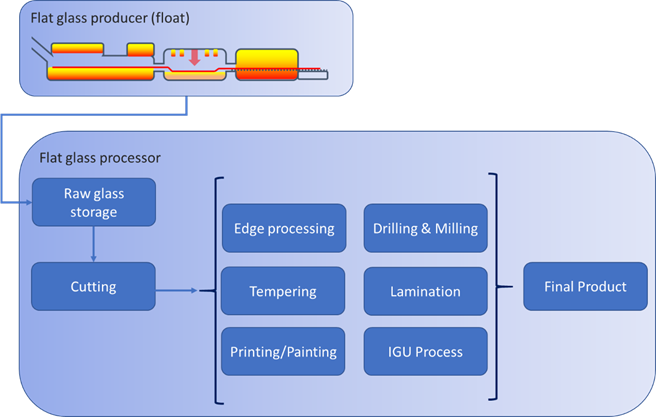

Focusing on flat glass, the principal process steps for flat glass products are shown in simplified form in Figure 3.

Figure 3 – Typical processing steps in flat glass production

Flat glass can be produced in two ways. The first is by the use of the float process, a second possibility is the rolled glass process. Float glass producers hold large glass tanks to melt and pull glass in the desired thickness and application of required coating. Such glass with a thickness between 2 and 20 mm, typically cut to size of 6000 x 3210 mm and stocked on racks for transport, is typically the raw material for the flat glass processors. The flat glass processor transforms the raw glass into divers glass products of various sizes and shapes such as window glass, splash backs, shopfronts, stairs, tables etc. In any case, the cutting process is the most universal process that is required for basically all raw glass processings and therefore the example of flat glass cutting is used in the subsequent chapters as reference object. The most important processes are described in more detail below:

- Cutting: mechanical flat glass cutting is a sequenced process in which:

- a raw glass pane is transported from storage to the cutting table

- the cutting pattern is inscribed onto the glass surface, e.g., by means of a very small sharpened stainless-steel wheel

- the glass is broken along the prescribed lines by applicating a bending force, either manual or automatic

- optional, there may be a grinding head mounted, allowing to eliminate existing glass coating on prescribed areas

- special cutting for previously laminated glass, where as an additional process after the glass breaking the foil attaching the 2 glass panes is separated mostly by a thermomechanical process.

- Processing: Flat glass processing can include :

- Edge works, such as edge seaming, grinding and or polishing

- Surface works, such as drilling holes or generating cut outs, required e.g. for inserting of hinges and handles as required for shower doors.

- Heat treatment, like tempering to change tension and behaviour of glass, as e.g. required for car side windows (tempered glass which in case of break dissipates in small cullets)

- Bending (heating plus application of gravity or pressing force) to change the glass shape into curved glass

- Assembly: multiple glass panes may be assembled to (semi-) products

- Lamination, in which multiple glass panes are glued together by means of interlaying thermoplastic foils. For this process the glass is first cleaned, then stacked with the interlayers and further processed in a thermopressure process to initiate the robustness of the product and the required transparency.

- Insulating Glass production: for windows and facade elements in which two or more glass panes are assembled holding glass spacers between the glass elements. The resulting volume is in general filled with inert gas such as Argon to ensure high insulation values.

For OPC UA modelling it is required to respect main characteristics of flat glass processing:

- Glass processing is very individual and a good example of industrial batch size of a production.

- As a result, all machinery must be able to receive information on single glass element base in contrast to mass production.

- Glass processing is very often based on intensive co-working between machine and human. Thus, processes with non-digitized interfaces shall be possible.

As the OPC UA model shall be universal for flat glass processing, resulting major requirements are deducted.

One of them is that we have different types of transformation processes:

- One to many: Cutting, where raw glass panes are cut into multiple glass elements

- One to one: Mainly single glass element transformation processes such as edge and surface works, heat treatment, painting

- Many to one: Classical assembly processes such as lamination and insulating glass fabrication

- In order to establish an OPC UA Model suitable to the different processes, the main requirements of information transport and modelling, established over years in the glass industry, shall be integrated. A job is defined as concrete work order for one or more glass elements. For the transformation, the job may reference to preadjusted work recipes in the respective machines or production lines recipes by means

- Jobs can be grouped in a job group (as a set of job in a fix order)

- The order of jobs and of job groups may be changed

- Each job group and job have a status (see ProductionStateMachine)

- Each transformation process is one job, e.g.,

- Cutting 100 raw glass panes requires 100 jobs as each pane will be cut in an individual pattern.

- IGU Line production of a lot requires an individual setting for each glass element produced.