Due to the climate and energy crisis, industrial companies are faced with the challenge of taking appropriate steps to efficiently manage their own energy requirements. The introduction of an energy management system according to the ISO 50001 standard [1] has proven to be a promising approach in the past. The introduction of such an energy management system provides the organizational framework for deriving energy efficiency actions based on recorded energy data, implementing them, and monitoring their effects. In this context, the procedure is continuously monitored and optimized through the application of a so-called Plan-Do-Check-Act cycle, so that energy inputs are constantly made more energy-efficient. In addition to the organizational part, an energy management system also needs a technical part that can be used to measure, provide, store, display and evaluate energy data. Furthermore, energy demands can be directly influenced by a load management system. With standby management functions, devices or entire plant sections can be ramped down to an energy-saving mode during production pauses, e.g. when cleaning of the production plant is required. The components of the required technical part can be termed as technical energy management system [2].

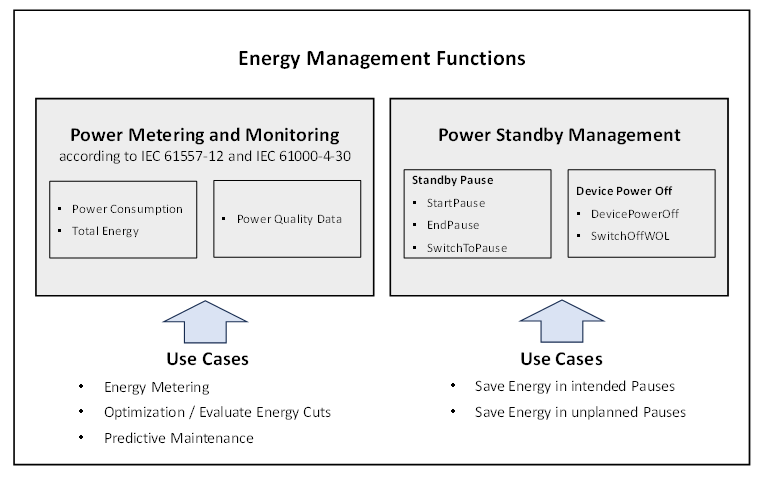

The functions of such a technical energy management system are clustered according to Figure 2 and show the basic functional submodels scoped by this specification. The cluster “Power Metering and Monitoring” functions provides energy related measurement values to cover the use case for energy consumption monitoring and metering and energy related measurement values to cover the use case power quality monitoring. The electrical measurement values in this cluster are based on the standards IEC 61557-12 [4] and IEC 61000-4-30 [6].

The cluster “Power Standby Management” addresses the switch down of components and devices to a power standby or power off mode in cases the component or device is temporarily not needed in the production process. This can be the case for planned pauses like lunchtime or maintenance or because of unplanned pauses caused by defects in the production line and temporary interruptions in the supply chain. The power standby management cluster contains basically two different modes for standby. The standby pause management assumes that the ethernet or fieldbus interface at the device is still operative and the device is able to receive commands for management of the standby pause states of the device. The device power off management causes a complete power down of the device, leaving only the ethernet MAC functionality operative in order to be able to receive an ethernet WOL magic package to conduct the standard ethernet wake on LAN functionality.

Figure 2 – Energy Management Functions scoped by the specification