The specification “Energy Consumption Management” defines a standardized information model on OPC UA for the purpose of defining interoperable interfaces and a standardized semantic for energy management systems in industrial automation and process automation industries. The purpose of an energy management system is to save overall energy consumption and energy costs, as well as the fulfilment of regulatory standards like ISO 50001 [1] and the protection of the climate.

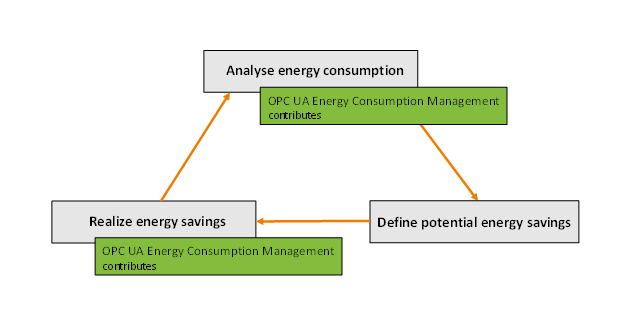

As Figure 1 shows, the general approach to cut down overall energy consumption and energy costs is a step-by-step circular approach. Starting point is the analysis of today energy consumption. With awareness about energy consumption of sections, machines and devices in the production plant, in a next step potential energy savings are identified. After the definition of potential energy savings, the next step is the realization of the identified savings.

The specification Energy Consumption Management is on the communication of energy related measurement data, which is to be used in the task of “analyse energy consumption” and in the advertisement and control of energy savings in the task of “realize energy savings”. Existing OPC UA models for Energy Management (OPC 30141) together with other fieldbus energy profiles serve as the basis for this companion specification. Also, the universal energy information model out of the project results of the IGF research project 21329 N “Development of energy management interfaces for IoT technologies (IoT_EnRG) ” [3] was used here.

Figure 1 – General Approach and Contribution of Specification for Energy Management

It will allow management of energy consumption by automated equipment in manufacturing and processing applications for discrete and continuous productions. The model is intended to be scalable from small stand-alone devices to complete machines to production cells or entire factories and plants.