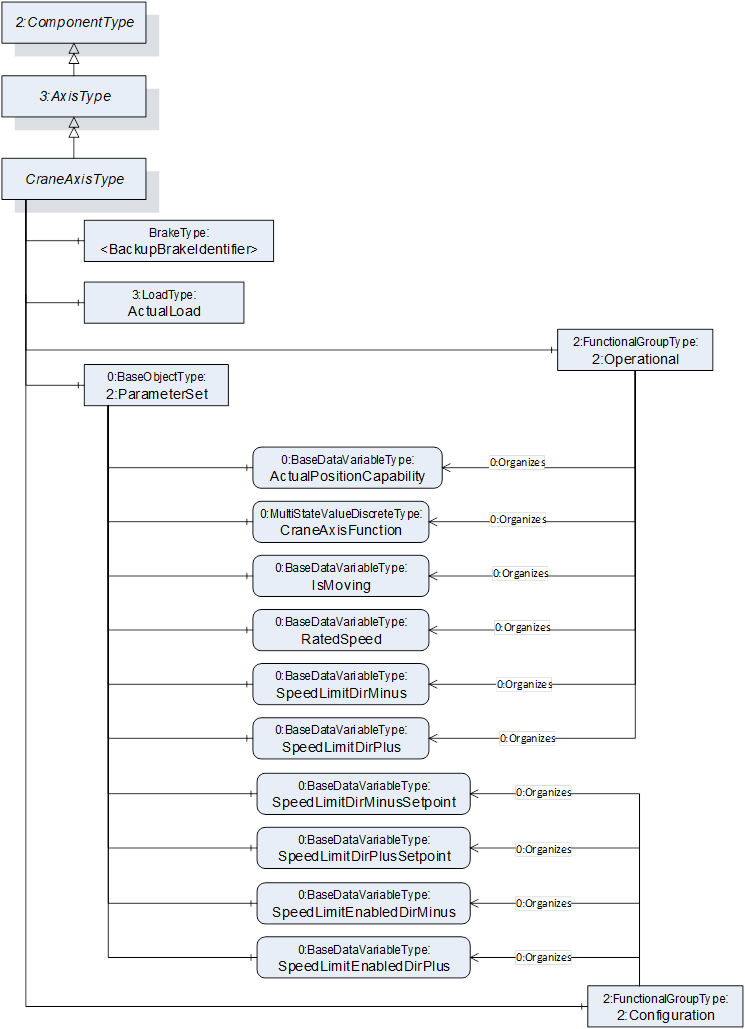

Figure 12 – Overview CraneAxisType

The CraneAxisType represents the crane axis and contains its various components. The type is a subtype of the OPC 40010-1 AxisType (OPC Robotics) and this is intended to provide compatibility with OPC 40010-1 aware clients. The CraneAxisType is formally defined in Table 16.

Table 16 – CraneAxisType Definiton

|

Attribute |

Value |

||||

|

BrowseName |

CraneAxisType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of the 3:AxisType defined in OPC 40010-1, i. e. inheriting the InstanceDeclarations of that Node. |

|||||

|

0:HasComponent |

Object |

ActualLoad |

|

3:LoadType |

O |

|

0:HasComponent |

Object |

<BackupBrakeIdentifier> |

|

BrakeType |

OP |

|

0:HasComponent |

Object |

2:Configuration |

|

2:FunctionalGroupType |

O |

|

0:HasComponent |

Object |

2:Operational |

|

2:FunctionalGroupType |

O |

|

Conformance Units |

|||||

|

Cranes Base Info CraneAxisType |

|||||

The ActualLoad object represents the load lifted by the crane. This object is mostly used in hoisting axis. The type (LoadType) is the one defined by OPC 40010-1 (OPC Robotics) and is used to represent the mass of the load, and optionally also inertia and/or the center of mass.

The <BackupBrakeIdentifier> object indicates that the axis may contain one or more backup brakes represented by BrakeType instances.

The Operational FunctionalGroup contains variables which represent the current state of the axis. These are read-only variables.

The Configuration FunctionalGroup contains variables which can be used to assess and/or affect the control of the axis, such as setting speed limits.

The components of the CraneAxisType have additional subcomponents which are defined in Table 17.

Table 17 – CraneAxisType Additional Subcomponents

|

BrowsePath |

References |

NodeClass |

BrowseName |

DataType |

TypeDefinition |

Others |

|

2:ParameterSet |

0:HasComponent |

Variable |

ActualPositionCapability |

0:Boolean |

0:BaseDataVariableType |

M, RO |

|

2:ParameterSet |

0:HasComponent |

Variable |

CraneAxisFunction |

0:UInt16[] |

0:MultiStateValueDiscreteType |

O, RO |

|

2:ParameterSet |

0:HasComponent |

Variable |

IsMoving |

0:Boolean |

0:BaseDataVariableType |

O, RO |

|

2:ParameterSet |

0:HasComponent |

Variable |

RatedSpeed |

0:Double |

0:AnalogUnitType |

O, RO |

|

2:ParameterSet |

0:HasComponent |

Variable |

SpeedLimitDirMinus |

0:Double |

0:AnalogUnitType |

O, RO |

|

2:ParameterSet |

0:HasComponent |

Variable |

SpeedLimitDirMinusSetpoint |

0:Double |

0:AnalogUnitType |

O, RW |

|

2:ParameterSet |

0:HasComponent |

Variable |

SpeedLimitDirPlus |

0:Double |

0:AnalogUnitType |

O, RO |

|

2:ParameterSet |

0:HasComponent |

Variable |

SpeedLimitDirPlusSetpoint |

0:Double |

0:AnalogUnitType |

O, RW |

|

2:ParameterSet |

0:HasComponent |

Variable |

SpeedLimitEnabledDirMinus |

0:Boolean |

0:BaseDataVariableType |

O, RW |

|

2:ParameterSet |

0:HasComponent |

Variable |

SpeedLimitEnabledDirPlus |

0:Boolean |

0:BaseDataVariableType |

O, RW |

|

2:Operational |

0:Organizes |

Variable |

ActualPositionCapability |

0:Boolean |

0:BaseDataVariableType |

M, RO |

|

2:Operational |

0:Organizes |

Variable |

CraneAxisFunction |

0:UInt16[] |

0:MultiStateValueDiscreteType |

O, RO |

|

2:Operational |

0:Organizes |

Variable |

IsMoving |

0:Boolean |

0:BaseDataVariableType |

O, RO |

|

2:Operational |

0:Organizes |

Variable |

RatedSpeed |

0:Double |

0:AnalogUnitType |

O, RO |

|

2:Operational |

0:Organizes |

Variable |

SpeedLimitDirMinus |

0:Double |

0:AnalogUnitType |

O, RO |

|

2:Operational |

0:Organizes |

Variable |

SpeedLimitDirPlus |

0:Double |

0:AnalogUnitType |

O, RO |

|

2:Configuration |

0:Organizes |

Variable |

SpeedLimitDirMinusSetpoint |

0:Double |

0:AnalogUnitType |

O, RW |

|

2:Configuration |

0:Organizes |

Variable |

SpeedLimitDirPlusSetpoint |

0:Double |

0:AnalogUnitType |

O, RW |

|

2:Configuration |

0:Organizes |

Variable |

SpeedLimitEnabledDirMinus |

0:Boolean |

0:BaseDataVariableType |

O, RW |

|

2:Configuration |

0:Organizes |

Variable |

SpeedLimitEnabledDirPlus |

0:Boolean |

0:BaseDataVariableType |

O, RW |

The ActualPositionCapability describes if the crane is able to give the position of the axis. The crane must be equipped with the necessary devices to provide this type of information. If the variable value is True, the axis position can be obtained from the variable ActualPosition inherited from the OPC 40010-1 (OPC Robotics).

The CraneAxisFunction describes the axis operating mode. The possible values are described in Table 18.

The IsMoving indicates if the axis is moving (TRUE) or not (FALSE).

The RatedSpeed indicates the rated (nominal) speed of the axis.

The SpeedLimitDirMinus indicates the speed limitation value active on the control system, in direction where position value decreases, in percentage of rated speed, range [0%..100%].

The SpeedLimitDirMinusSetpoint indicates the speed limitation request written from client, in direction where position value decreases, in percentage of rated speed, range [0%..100%].

The SpeedLimitEnabledDirMinus indicates a speed limitation request active, written from client, in direction where position value decreases. True if a client requests the speed to be limited in this direction, false if speed doesn't need to be limited.

The SpeedLimitDirPlus indicates the speed limitation value active on the control system, in direction where position value increases, in percentage of rated speed, range [0%..100%].

The SpeedLimitDirPlusSetpoint indicates the speed limitation request written from client, in direction where position value increases, in percentage of rated speed, range [0%..100%].

The SpeedLimitEnabledDirPlus indicates a speed limitation request active, written from client, in direction where position value increases. True if a client requests the speed to be limited in this direction, false if speed doesn't need to be limited.

To be extendable for vendor specific extensions later, the TypeDefinition is MultiStateValueDiscreteType with its mandatory Properties EnumValues and ValueAsText must be filled with the supported values which are defined in Table 18. The EnumValues Property is an array of EnumValueType. Each entry of the array represents one enumeration value with its integer notation, a human-readable representation (DisplayName), and a description. Each instance shall have the values 0 to 8, which are defined in Table 18. Element numbers 9-15 are reserved for future use. If vendors add specific elements, the range 9-15 shall be filled with ‘null’-strings. The variable CraneAxisFunction exposes the current integer notation in their Value Attribute. The ValueAsText Property shall provide the localized text representation of the current enumeration value (Value Attribute of Variable CraneAxisFunction).

Table 18 – Items of EnumValues array of CraneAxisFunction

|

Value |

DisplayName |

Description |

|

0 |

RATED_SPEED |

The axis moves at rated speed. |

|

1 |

EXTENDED_SPEED |

The axis moves above the rated speed when load is under certain percentage of rated load. This function reduces the load cycle time and can be used for hoisting.

|

|

2 |

MICROSPEED |

Microspeed turns large joystick movements on the operator interface into slow and exact load movements. This function assists in very accurate and precise load handling and reduces the risk of collision and can be used for hoisting and travelling.

|

|

3 |

INCHING |

Inching is designed to ensure accurate final load positioning by allowing the crane operator to move the load in small increments. This function assists in very accurate and precise load handling and reduces the risk of collision and can be used for hoisting and travelling.

|

|

4 |

ANTISWAY |

This function limits load swing by controlling the bridge and trolley acceleration and deceleration. Antisway allows faster load handling and more precise positioning. This feature also reduces the risk of damage to the load, crane and surrounding area. |

|

5 |

TANDEM_HOIST |

Two or more hoists are operated from a single control station for handling of a single load. Two or more load lifting attachments’/hooks’ positions are synchronized. This function gives more accuracy when two or more hoists are used at the same time. Hoisting speeds are the same within the tolerances required for the particular application. |

|

6 |

TANDEM_TROLLEY |

Two or more trolleys are operated from a single control station for handling of a single load. Horizontal speeds are the same within the tolerances required for the particular application. |

|

7 |

TANDEM_CRANE |

This function allows the operator to control two cranes at the same time from one control station. The operator controls two cranes as one. This feature is useful when the operator needs to handle a single load with two cranes. |

|

8 |

PRESET_DESTINATION |

This function allows the operator to move the crane to a predefined position without effort. With a single operator input, the crane carries out the sequence to reach the selected destination. |

|

9 - 15 |

null |

null |

|

≥ 16 |

Vendor specific |

Vendor specific description |