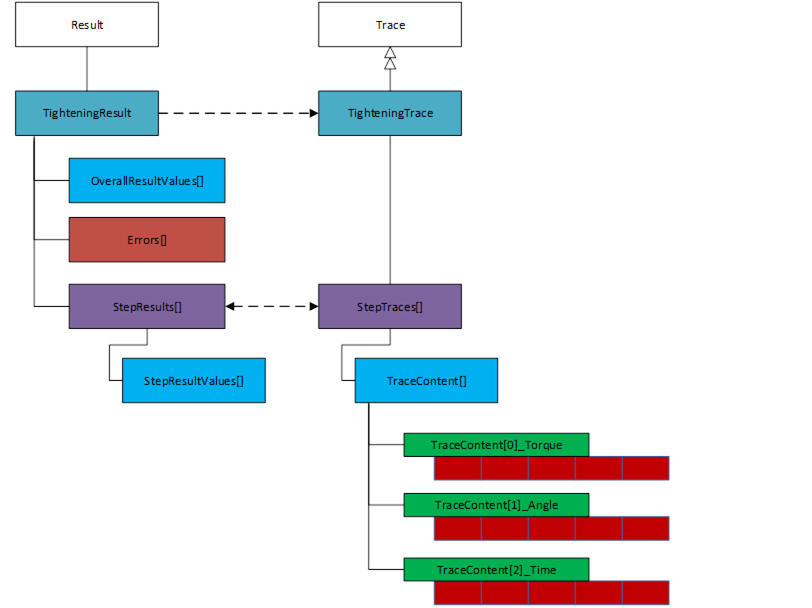

Overview of Tightening Result and Tightening Trace

The following result and trace model are flexible to cover different type of tightening systems.

Result and Trace instances have the required properties and references to link a result, step result and traces.

Figure 22 - Result and Trace Overview Example

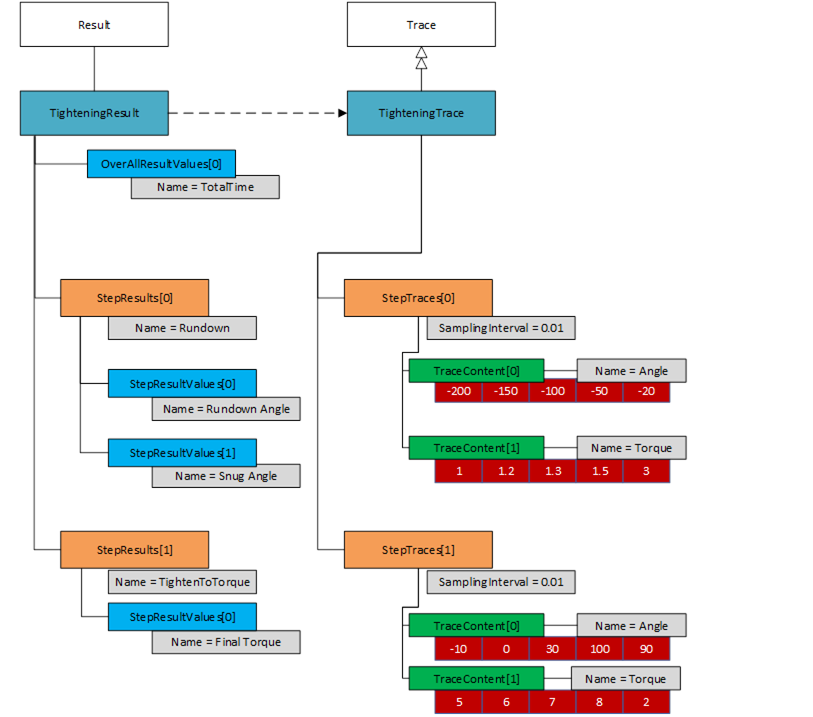

Overview of Result and Traces with Sample Data

The following figure illustrates a simple example of modeling the Result and Trace. For simplicity, only a few parameters are listed in the example.

Figure 23 - Result and Traces Example with Sample Data

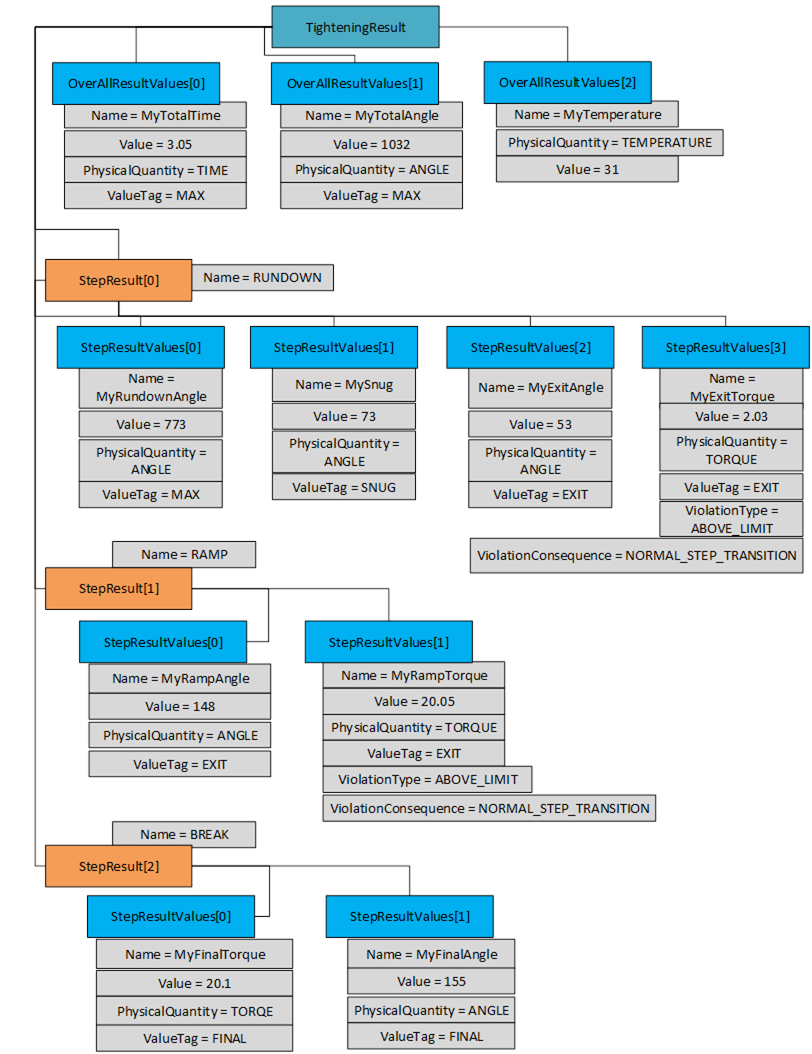

Result with OverallResultValues, Step Result Values and Value Tags

The following figure illustrates an example of OverallResultValues and StepResultValues for a three-step tightening. Please note that most other parameters have been omitted to clarify the use of ResultValues and ValueTags.

This example has three general values that is not tied to a particular step. These are MyTotalTime (the time from start to finish of the entire tightening), MyTotalAngle (the angle from start of rundown to highest achieved angle), and MyTemperature. The first two values have ValueTag = MAX to make it easier to understand that it is global maxima we are reporting. The temperature is tied to a single sampling, so it is included as a reported value without any ValueTag.

The result contains a rundown step, a simple torque step and a break step.

There are four values which contain an EXIT ValueTag, these represent the values as one step transition into the next. Two of them has a ViolationType value, meaning that they are the cause of the transition.

The last step (the break step) contain the angle and torque of the Final Torque point. Both have the FINAL ValueTag. To get hold of the FINAL values, the result consumer needs to loop through the Steps and the StepResultValues and look for the FINAL ValueTag.

Figure 24 - OverallResultValues, StepResultValues and Value Tags Example

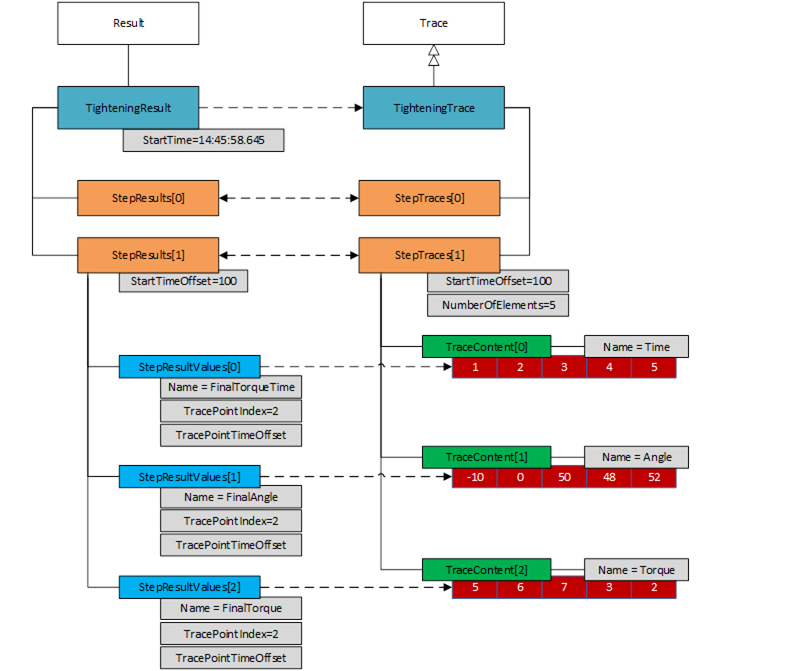

Linking a Tightening Result and Tightening Trace

The following figure illustrates an example to reference a point of interest (such as Final Torque, Final Angle, etc.) to a given trace sample in two different ways based on the use cases.

The Trace model is defined to have same number of trace points for different trace samples for a given Tightening trace.

The following example represents a result generated from a two-step tightening program and the reference of a specific point of interest is mapped from second step result to a second step trace based on TracePointIndex.

In some use cases, a point of interest (e.g. Final Torque point, etc.) could be an available value in the Trace sample array and in that case, the system can provide a specific index value in the ResultValueType structure using the TracePointIndex property.

In some use cases, when a given point of interest (e.g. Final Angle, Final Torque, etc.) is not available in the Trace sample array, an additional property TracePointTimeOffset can be used to map the given sample using the StartTime, StartTimeOffSet (of a given step) and TracePointTimeOffSet.

Figure 25 - Result and Trace Sample Linking Example

Result and Trace Value Evaluation

This section illustrates when a given result or trace value can be positive or negative.

Tightening Programs

Increased torque during a step that rotates in the same direction as the program direction produce increasing positive torque values.

Increasing torque during a step that rotates in the opposite direction to the program direction produce increasing negative torque values.

Angle values increase when we tighten the bolt and decrease when we loosen the bolt.

Loosening Programs

The torque values increase during a step that rotates the tool tap in the loosening direction, i.e. the opposite direction to the tightening program direction.

The torque values decrease during a step that rotates the tool tap in the tightening direction, i.e. same direction as the tightening program direction.

Angle values decrease when the tool tap rotates in the loosening direction, i.e. opposite direction to the tightening program direction.

Angle values increase when the tool tap rotates in the same direction as the tightening program direction.