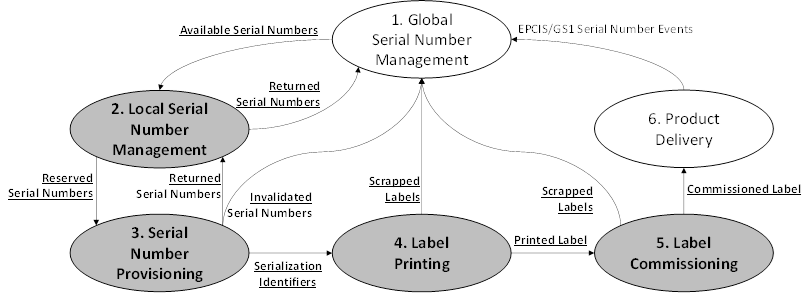

The activities of serialization are illustrated in Figure 2. Each of the activities may be performed for each level of a packaging aggregation hierarchy, such as separate serial number management, provisioning, printing, and commissioning for pallet labels, and similar activities for cases and cartons. The scope of the OPC UA OPEN-SCS implementation are information exchanges between the activities. Not all communication exchanges are shown in Figure 2.

Figure 2 – Activities in Serialization

- Global Serial Number Management – This is the activity of creating, allocating, registering, and general management of Serial Numbers. This activity may be local (within a company) or remote in a regulatory agency or a third party. Generally, this activity is global in scope, even within a company, in order to ensure that uniqueness of Serial Numbers. Global serial number management may deal with any Serial Number state, but generally deal with unassigned, invalid, scrapped, destroyed, commissioned, sampled, or inactive states.

- Local Serial Number Management – This is the activity of managing available Serial Numbers, assigning Serial Numbers to production of specific products, packages, or aggregations. Generally, this is local in scope (within a company, a site within the company, or area within the site) in order to meet performance requirements in obtaining Serial Numbers for provisioning. If locally managed Serial Numbers which have not been commissioned and will not be used, they are generally returned to global serial number management for possible reuse.

- Serial Number Provisioning – This is the activity of associating a Serial Numbers with a specific production run. This activity is generally performed locally (within a company, a site within the company, or area within the site), but may be done by a third party that is pre-printing labels. This activity may be done some time before the label is printed, because of limitations in the printing system, or just-in-time if available on the printing system. If Serial Numbers cannot be used (such as more are provisioned than are needed for the production run), then the unused numbers are either returned to local or global serial management for possible reuse or reported as invalid for tracking purposes.

- Label Printing – This is the activity of printing the Serial Numbers and related information on a label. This is usually in the form of a 1D barcode, QR (2D), DataMatrix or RFID tag. If the printed labels are scrapped before they are commissioned, then the Serial Numbers associated with the labels are usually returned to local or global serial number management indicating that labels with the serial numbers were printed, but the labels were scrapped.

- Label Commissioning – This is the activity of associating a label with a product or package. Typically this involves attachment of the label to the product or package. If the association is later removed and the label scrapped, such as the label being removed from the product/package because of rework of the product, then the Serial Numbers on the scrapped label are reported to local or global serial number management for tracking. Once the Serial Number is associated with a product, package, or aggregation it is known as a SID.

- Product Delivery – This is the activity of shipping the product/package out of the custody of production to other parts of the business or the supply chain. If the product is destroyed or otherwise made non-usable, then the destroyed Serial Numbers are usually returned to global serial number management for tracking. Often the transfer of custody is to local warehouses or shipping departments.

Each of the activities may be performed for each level of a packaging aggregation hierarchy, such as separate serial number management, provisioning, printing, and commissioning for pallet labels, and similar activities for cases and cartons.