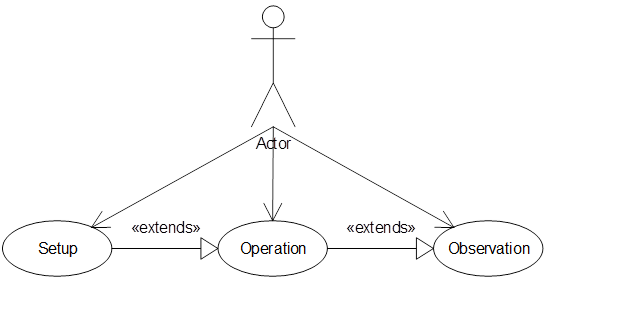

This companion standard is meant to be used for CNC data interfaces. It allows to access data provided by a CNC system, namely parameters, state data, process and command data, alarm notifications and files. Access covers both read and write access. Thus, the following use cases may be covered:

- Setup: The CNC data interface provides data that can be used for setting up a production system controlled by a CNC. This refers first of all to production commissioning data (e.g. job description, tool data etc.) but implies to a certain extent as well CNC configuration data (e.g. axis parameters, cycle time etc.), as needed for engineering.

- Operation: The CNC data interface may be used for operating a production system controlled by a CNC and therefore serves as a connection point for user interfaces.

- Observation: The CNC data interface may be used for observing a production system controlled by a CNC and therefore serves as a connection point for monitoring and diagnosis applications and for user interfaces.

Figure 5 shows the use case diagram.