The advantages of the Weihenstephan Standards are that they greatly simplify the definition of MES functionalities and the data points required for them during the project planning phase. In the implementation phase, the time required can be greatly reduced by using WS tools, which leads to a considerable reduction in costs.

This is possible because the Weihenstephan Standards take on three tasks (see Figure 1):

- exemplary definition of MES functionalities that are specifically tailored for a WS domain

- definition of data points derived from the MES functions

- definition of the communication protocol and information model between the data sources and the MES

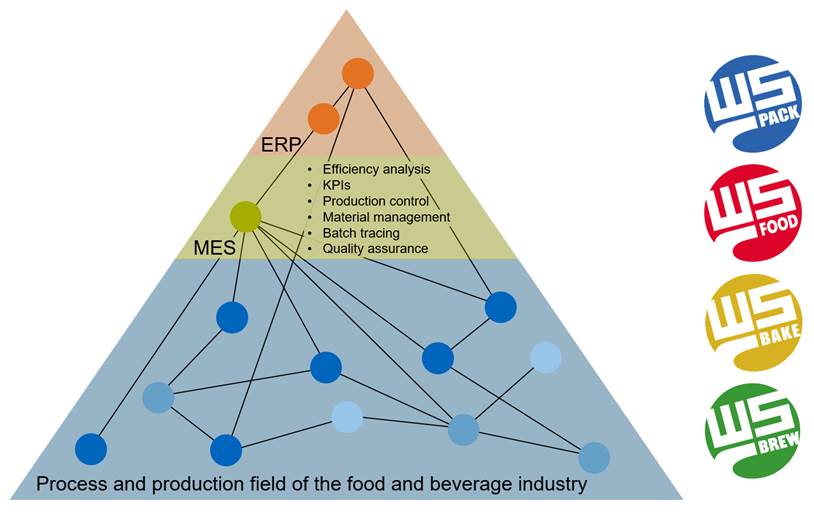

Figure 1 – Communication via Weihenstephan Standards

On the way to Industry 4.0, the hierarchical structures of the automation pyramid are breaking down more and more. This is also reflected in the Weihenstephan Standards, the data points required for the MES functionalities are not only provided directly by machines. Instead, the data is already aggregated and made available by process control systems, for example. Figure 1 illustrates the structured communication between an MES and different communication partners in a heterogeneous system for the provision of data according to the Weihenstephan Standards.