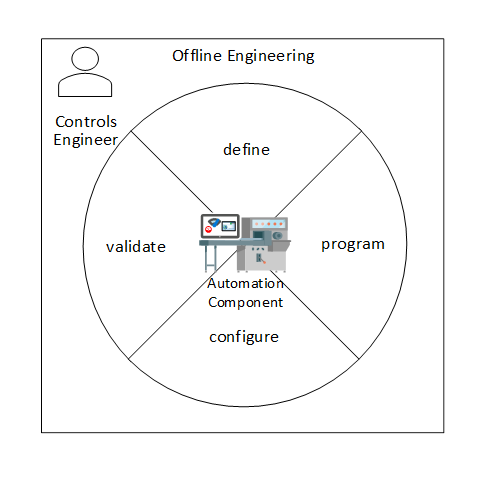

OfflineEngineering is an essential phase in the lifecycle of an AutomationComponent. By allowing the Controls Engineer to define, program, configure and partially validate the operation of an AutomationComponent before deploying the AutomationComponent in physical hardware, the Controls Engineer will be more confident that the AutomationComponent performs the automation functions reliably and correctly once the physical AutomationComponent is in place. This can be seen in Figure 1.

Figure 1 – OfflineEngineering for an AutomationComponent

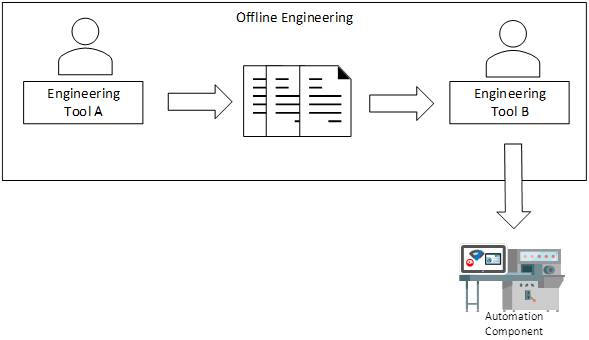

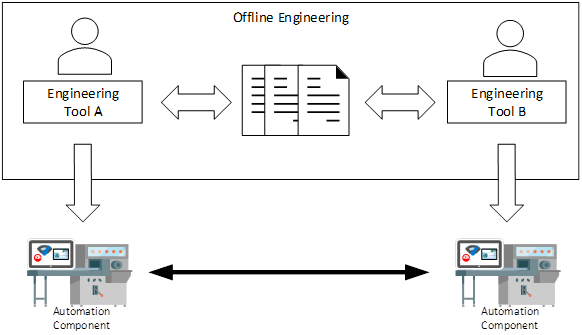

An important task of the OfflineEngineering phase is the definition of the Information Model of an AutomationComponent. In this task, Controls Engineers design, edit, share, store, and provision Information Models of an AutomationComponent. This task can take several steps, where Controls Engineers design the Information Model of an AutomationComponent in iterations and pass it from one engineering tool to another (Figure 2). They also share Information Models of AutomationComponents (Figure 3).

Figure 2 – Engineers work in sequence on the Information Model of one AutomationComponent

Figure 3 – Engineers mutually exchange Information Models of AutomationComponents

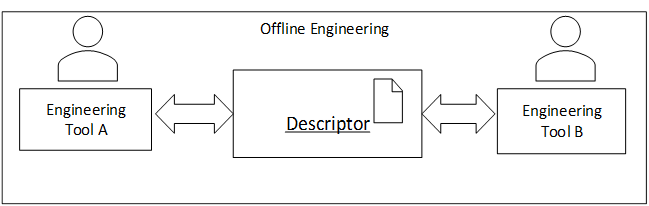

In order to facilitate the exchange and storage of Information Models and data between Controls Engineers, the concept of “Descriptor” is introduced, as shown in Figure 4. The Descriptor takes the shared information and organizes the information in a formal electronic format with defined properties. The Descriptor allows for standardized exchange of data between Controls Engineers and engineering tools.

Figure 4 – Engineers and Engineering Tools exchange a Descriptor during OfflineEngineering