Overview

The intention of Value Tags is to point out reported values of special meaning in a result.

These special values are not present in all types of use cases, so ValueTags should only be added where it makes sense.

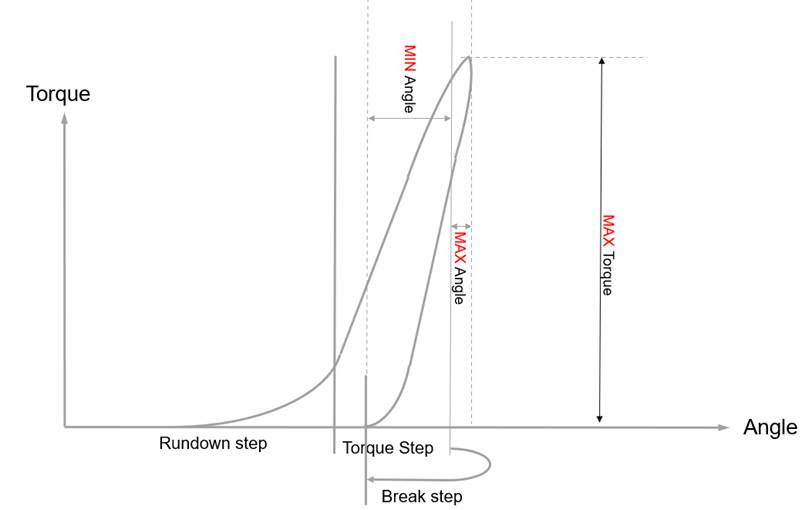

Refer the following figure for example Figure 24.

Regarding ValueTagged angle values

Value Tagged angle value are more complex than for example torque values in the sense that it is a relative angle between the point of interest and a reference point. The reference point will be the origin in the angle coordinate system and every angle value before that point will have negative angle values.

This origin point can be configured differently on different systems and between different tightening programs. Some common cases of defining the origin is to

- tie it to when a configured torque level is reached (in Figure 18) , the dotted horizontal line would represent a configured torque level, and the angle would be just as in the picture), or

- tie it to a step transition (in Figure 18), that would make the FINAL angle denote the angular difference between the solid line between the rundown step and the FINAL point), or

- tie it to the snug point as described in the SNUG paragraph, or

- tie it to the beginning of the tightening, thereby including the full rundown in a reported FINAL angle. (This would mean every reported angle would be positive unless it is a loosening)

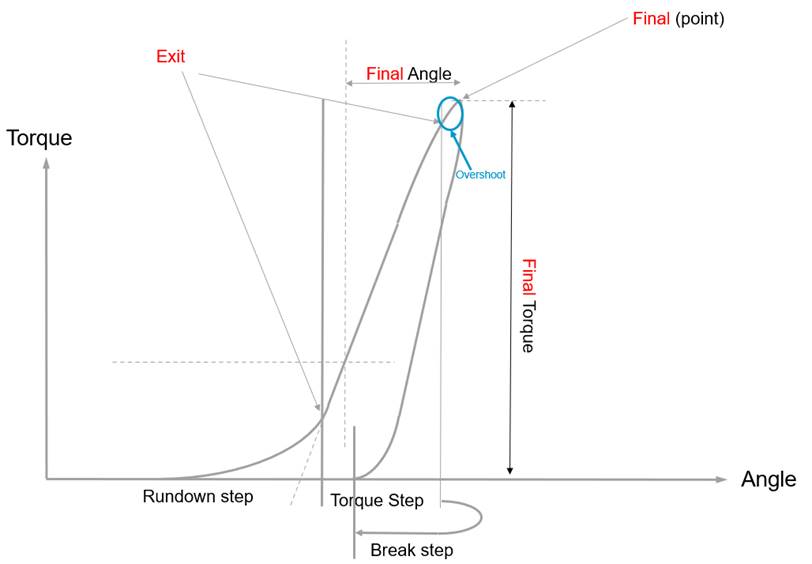

FINAL

The FINAL ValueTag is most common in handheld systems, and is intended to mark the point where the torque generated the clamp force that is left in the joint, after the tightening is completed.

There will often be up to three values associated to the final point: an angle value, a torque value, and a time value. All having the FINAL ValueTag.

The torque value is straightforward, denoting the torque left in the joint, from the tightening systems perspective.

The FINAL angle value is a naturally relative to the defined origin as discussed above.

Note 1: The FINAL torque value is intended to represent what the tightening tool perceives as the torque applied to the joint. There are at least two physical phenomena that interact to make the result of a residual torque check report a different torque value. The first is the seating of the joint. Over time the material of the bolt settles causing the clamp force and torque resistance in the bolt getting lower. The second is the difference between static and dynamic friction. When the bolt is being tightened, the (dynamic) friction is lower than the (static) friction that should be overcome to start the bolt rotating. These two phenomena work against each other and are dependent on such things as temperature, material, lubrication, passed time, etc.

The seating of the joint takes place over time after the tightening. This often means that when a residual torque check is performed, the value will be lower that the reported FINAL torque of the tightening.

Note 2: Sometimes (according to configuration) the prevailing torque (the torque at the SNUG point) will be subtracted from the value before it is reported as FINAL torque. This is done to separate the torque needed overcome the friction/deformation of the joint from the torque used to create clamp force. In these cases, it is recommended to also include both the prevailing torque and the actual absolute max torque as reported values in the result.

Figure 18 - Final and Exit Example

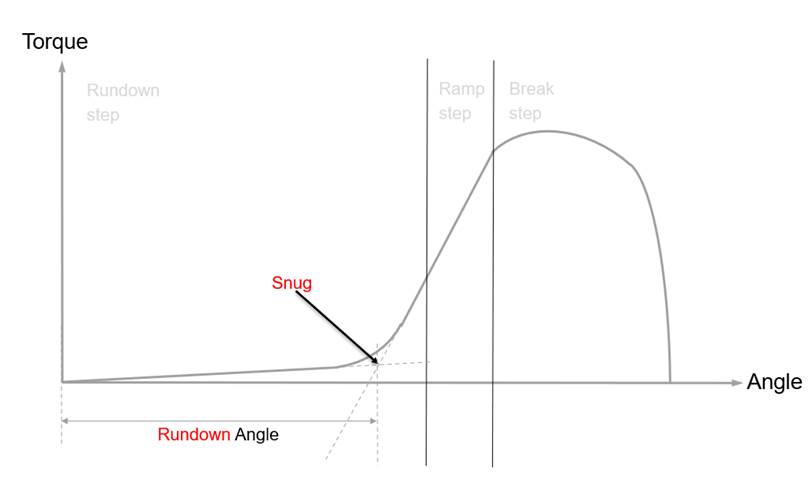

SNUG

The SNUG ValueTag is the reported point where screw head touches the surface and all parts have mated.

There is no common agreed definition of snug today in the industry. Until one is decided, this specification will use the SNUG ValueTag to denote the intersection of the linear approximation of the rundown and the tightening ramp. Most often the reported SNUG value is a rough approximation of this since the disturbance in the signal combined with the nature of the bended part of the curve makes it difficult to calculate exactly.

Figure 19 - Rundown and Snug Example

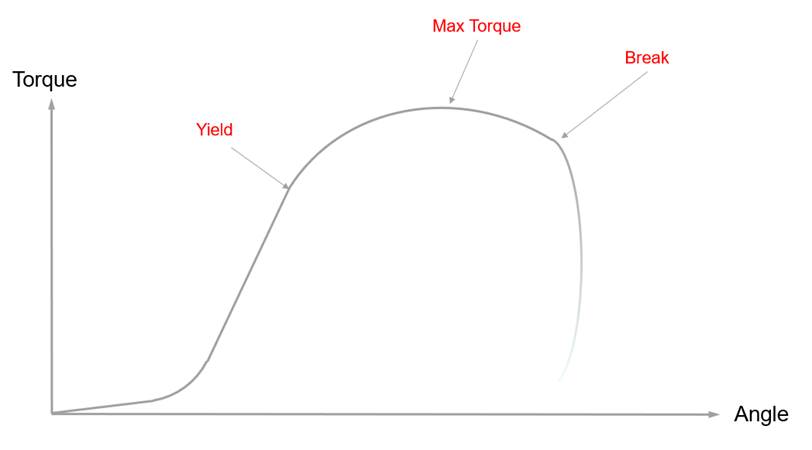

YIELD

The YIELD ValueTag is intended to denote the point where the material in the bolt goes beyond the state of elasticity and therefore undergoes plastic deformation, causing it to become permanently elongated.

The yield point is usually the area where the linear growth of torque versus angle is dropping.

Example: The picture below represents a tightening until the bolt breaks.

Just like SNUG, a YIELD point is difficult to calculate exactly and the tightening system will report an approximation.

EXIT

A value with an EXIT ValueTag signifies that it is measured when the step ends.

Example: If the EXIT value contains

- ViolationType = ABOVE_LIMIT_0 or BELOW_LIMIT_1, and

- ViolationConsequence = NORMAL_STEP_TRANSITION

you know that this variable is what actually caused the step transition

MAX and MIN

A value can be tagged with MAX if it represents the highest occurrence within that step.

A MIN value consequently is used to denote the lowest occurrence within a step.

Note: MAX and MIN values are evaluated including the boundary values of the step.

Example: In the picture below, the origin has been set to the transition point between the torque and the break step.

MAX angle is reached shortly after the FINAL torque point.

And the value containing a MIN angle ValueTag would likely also contain the EXIT ValueTag.