This section uses two suggestions to show how an exemplary machine could be implemented using this OPC UA Companion Specification. One example is used for low pressure plasma surface treatment machines and one for atmospheric pressure plasma surface treatment machines.

Instantiation of an exemplary low pressure plasma surface treatment machine

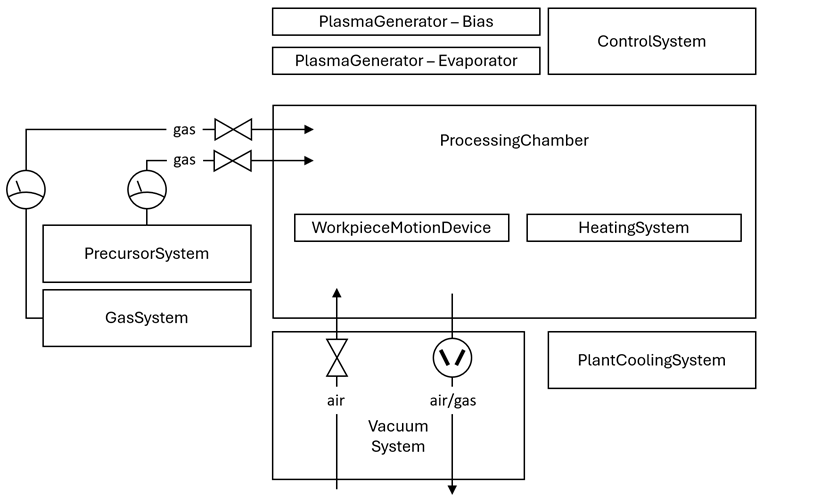

Figure 21 shows an exemplary low pressure plasma surface treatment machine

Figure 21 – Exemplary low pressure plasma surface treatment machine

A low pressure plasma surface treatment machine comprises several essential components to enable the diverse plasma surface treatments.

The processing chamber is the central component where the plasma treatment process takes place. It is a vacuum vessel. As the name of the machine type suggests, the plasma treatment process is carried out at low pressures, meaning below atmospheric pressure, typically in the range of a few hundred millibars to 10-4 mbar.

The major components within the processing chamber are the workpiece motion device and the heating system. Depending on the diverse treatment methods, various evaporation sources may also be present.

The workpiece motion device securely fixes the work pieces to be treated and rotates or moves them inside the processing chamber when it is needed to ensure even treatment. The heating system is designed both to heat the work pieces to a target temperature prior to the actual plasma treatment and to maintain the to be treated parts at a specific temperature level during plasma treatment.

The task of the vacuum system is to evacuate the processing chamber to a certain residual gas pressure, to maintain a predetermined pressure during the plasma treatment process and to ventilate the processing chamber back to atmospheric pressure.

Depending on the application in industrial plasma surface technology, corresponding systems require diverse pumps as part of the vacuum system that can evacuate the vacuum chamber from atmospheric pressure into the rough vacuum range of 300-1mbar up to the high vacuum range of 10-3-10-7mbar.

The gas system comprises the precisely regulated addition of pure or premixed process gases, reactive gases and cooling gases, usually via separate lines and gas flow controllers into the processing chamber. Often various different gases are needed to promote specific effects and reactions during the plasma treatment.

The precursor system is basically the same as the gas system. The main difference is the use of precursor feedstock, which is usually liquid. The precursor fluid must first be converted into a gaseous state via an evaporator system before the vapour / gas is injected into the supply line and fed into the processing chamber via gas flow controller.

The creation of layers in the plasma process occurs either the chemical rout meaning purely from the gas phase or through the physical rout by the evaporation of solids or powders or by combining these or different methods for coating synthesis. Plasma generators of various power levels, modes and frequencies are required to synthesize and grow both layers and crystals from the gas phase or to convert solid or powder source material into the vapour phase using various evaporator systems.

Basically and generally speaking, the plasma generator – bias is necessary for the surface activation of the workpieces. It generates the needed plasma. Devices of various power levels, modes and frequencies are used. The plasma generator – bias is usually connected directly with the workpiece motion device. In simple words, a quasi-neutral plasma is a combination of charged, excited, and neutral species. The bias is used to attract charged and exited gas and/or vapor species to the workpiece surfaces. Depending on the polarization the bias is used for various purposes such as electron heating, ion etching, ion incorporation, coating densification etc. during different process steps. Sometimes the plasma generator – bias is not directly attached to the workpiece motion device, but for instance to a so call plasma screen for indirect activation of the workpiece surface.

The control system is mainly a PLC / computer-based system that monitors and controls all process parameters. It is the brain of each low pressure plasma surface treatment machine. It provides monitoring of all critical parameters, relevant status information, recipe management and data logging features, etc.

For heat dissipation and to prevent overheating most of the components that are not air-cooled need water cooling. The plant cooling system ensures that all components are sufficiently cooled during the process, in general during entire use. This may be necessary for safety reasons (keyword: hot surfaces / contact protection) or to protect the individual components by keeping them within the permissible operating temperature limits. Cooling of air-cooled components as well as electronics can be supported by temperature controlled fan cooling / air conditioning (air/air, air/water heat exchanger).

shows how the example machine described can be implemented in an information model using OPC UA for PlasmaSurfaceTechnology.

The following page shows how the example machine described can be implemented in an information model using OPC UA for PlasmaSurfaceTechnology.

Figure 22 – Instantiation of the sample low pressure machine using the CS for PlasmaSurfaceTechnology

Instantiation of an exemplary atmospheric pressure plasma surface treatment machine

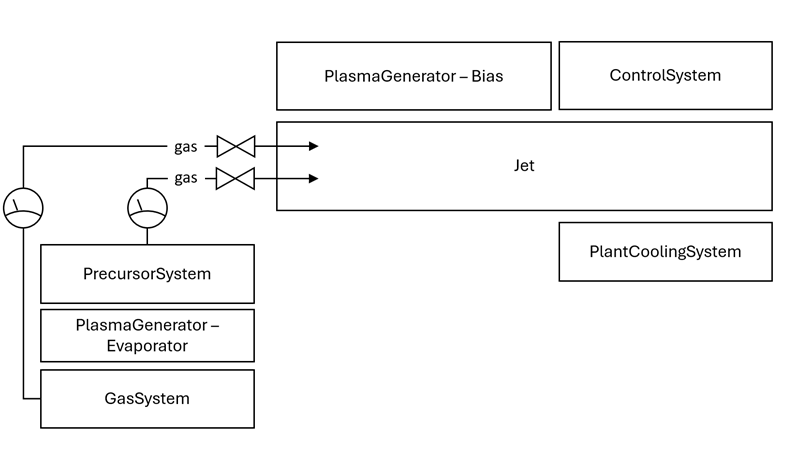

shows an exemplary atmospheric pressure plasma surface treatment machine.

Figure 23 – Exemplary atmospheric pressure plasma surface treatment machine

An atmospheric pressure plasma surface treatment machine comprises several essential components to enable the diverse plasma surface treatments.

The plasma jet is the central component where the plasma treatment process takes place. As the name of the machine type suggests, the plasma treatment process is carried out at atmospheric pressures, instead of below low pressure.

The plasma is generated inside the jet by a high voltage between a stator and a rotor and is blown out through the jet head using working gas that is provided by the gas system.

The atmospheric pressure plasma surface machine directed at the material serve to generate and spread the plasma. Plasma surface treatment is a versatile technique that can be used to improve the performance of materials in a range of applications.

The gas system comprises the precisely regulated addition of pure or premixed process gases, reactive gases, usually via separate lines and gas flow controllers into the processing jet. Often various different gases are needed to promote specific effects and reactions during the plasma treatment.

The precursor system is basically the same as the gas system. The main difference is the use of precursor feedstock, which is usually liquid. The precursor fluid must first be converted into a gaseous state via an evaporator system before the vapour / gas is injected into the supply line and fed into the jet via gas flow controller.

The creation of layers in the plasma process occurs either the chemical rout meaning purely from the gas phase or through the physical rout by the evaporation of solids or powders or by combining these or different methods for coating synthesis. In order to transfer solid or powder source material into the vapour phase plasma generators of various power levels, modes and frequencies are used for the wide range of different evaporator systems.

Basically and generally speaking, the plasma generator – bias is necessary for the surface activation of the workpieces. It generates the needed plasma. Devices of various power levels, modes and frequencies are used. The plasma generator – bias is usually connected directly with the workpiece motion device. In simple words, a quasi-neutral plasma is a combination of charged, excited, and neutral species. The bias is used to attract charged and exited gas and/or vapor species to the workpiece surfaces. Depending on the polarization the bias is used for various purposes such as electron heating, ion etching, ion incorporation, coating densification etc. during different process steps. Sometimes the plasma generator – bias is not directly attached to the workpiece motion device, but for instance to a so call plasma screen for indirect activation of the workpiece surface.

The control system is mainly a PLC / computer-based system that monitors and controls all process parameters. It is the brain of each atmospheric pressure plasma surface treatment machine. It provides monitoring of all critical parameters, relevant status information, recipe management and data logging features, etc.

An additionally plant cooling system cools a special jet to a constant temperature if needed.

The following page shows how the example machine described can be implemented in an information model using OPC UA for PlasmaSurfaceTechnology.

Figure 24 – Instantiation of the sample atmospheric pressure machine using the CS for PlasmaSurfaceTechnology