|

Term |

Definition |

|

Actual scale interval,d |

Value expressed in units of mass of: the difference between the values corresponding to two consecutive scale marks, for analog indication; or the difference between two consecutive indicated values, for digital indication. (OIML R51) |

|

Automatic scale |

An instrument that weighs without the intervention of an operator and follows a predetermined program of automatic processes, which are characteristic of the instrument. |

|

Current weight |

Defines the current value that is measured at the sensor at the concurrent timestamp. Might be a highly fluctuating value. |

|

Division |

Value of the smallest increment. See also (atual scale interval, verification scale interval) |

|

Feeder |

Devices for conveying the product to or from the weighing module |

|

Flow rate |

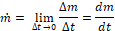

The flow rate is a measured value passes per unit of time. The flow rate can be defined as mass flow rate (flow of mass m through a surface per unit time t)

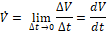

or as volumetric flow rate (flow of volume of fluid V through a surface per unit time t)

|

|

Gross value |

Indication of the weight value of a load on an instrument, with no tare or preset tare device in operation. (see OIML R 76) Weight of an objective or sample (net weight) including its container or packaging (tare weight) |

|

Height |

In direction of global gravity. |

|

Item |

A physical product in scales that process a set of physical products like catchweigher. In case a “productType” represented a set of physical products the single physical product is called item. |

|

Length |

In direction of travel. |

|

Load |

Amount of product that is currently introducing the force on the load receptor. (OIML R61) A general term for any Object when it is intended to convey the meaning that this Object is exerting a weight force |

|

Measurement result |

Set of quantity values being attributed to a measurand together with any other available relevant information (see VIM 2.9) |

|

Net value |

Indication of the weight value of a load placed on an instrument after operation of a tare device. (see OIML R 76) The weight of a material or sample after deducting the weight of its packaging or of the transport instrument (tare weight) |

|

PackML |

“PackML stands for Packaging Machine Language and is an interface standard originally used inbatch manufacturing in the packaging industry but which is now used in multiple different types of production and assembly lines.” (see OPC UA for PackML) |

|

Preset tare value |

Numerical value, representing a weight value, that is introduced into the instrument. It is a predetermined tare value that is used for one or several weighings. (see OIML R 76) |

|

Product |

For the purposes of this Companion Specification, a product is a physical good that is processed by a weighing system. Depending on the type of scale and type of good, the result may be a single weighing and/or a statistical evaluation of many weighing operations. Additional process steps (e.g. metal detection) can also be performed. A OPC UA Object of type "productType" represented a physical product or a set of physical products and contain additional (meta-)informations like a target value or some identifier. |

|

Proportional tare |

Tare value that is determined by the scale automatically and that is proportional to the gross weight. |

|

Recipe |

See Annex B |

|

RegisteredWeight |

Defines the last valid measurement that was recorded and will be used for further processing.. |

|

Scale |

Synonym: weighing instrument Measuring instrument that serves to determine the mass of an amount of material by using the action of gravity on this material.

NOTE: In this Recommendation “mass” (or “weight value”) is preferably used in the sense of “conventional mass” or “conventional value of the result of weighing in air” according to OIML R 111 and OIML D 28, whereas “weight” is preferably used for an embodiment (= material measure) of mass that is regulated in regard to its physical and metrological characteristics. The instrument may also be used to determine other quantities, magnitudes, parameters or characteristics related to mass. According to its method of operation, a weighing instrument is classified as automatic or non-automatic. (See OIML R 76) |

|

Scale division |

See division |

|

Scale system |

A scale system is the combination of several scales that are addressed by a common interface. A scale system can have additional functions, such as a state machine or a production preset. |

|

Setpoint |

Time at which an action is triggered |

|

Standard deviation |

A quantity expressing by how much the members of a group differ from the mean value for the group. |

|

Tare value,T |

Weight value of a load, determined by a tare weighing device. (see OIML R 76) The mass of packaging or transport container of the material that ist beeing weighed |

|

Target value |

Requested value of a variable size at a given time and under specified conditions. (see IEC 60050) |

|

Tolerable Negative Error (TU1) for prepackages |

Only a small number of prepackages may have a content below the nominal quantity minus the maximum permissible error (TU1-limit) (not more than 2.5%). These prepackages are known and referred to as ‘defectives’ (see Welmec 6.4) |

|

TU2-limit |

No prepackage with a quantity of product less than the nominal quantity minus twice the tolerable negative error (TU2-limit) may be ℮-marked. (see Welmec 6.4) |

|

Verification scale interval, e |

Value, expressed in units of mass, used for the classification and verification of an instrument. (OIML R51) |

|

Weighing |

Process of determining the mass of a load using the effect of gravity on that load (OIML R61) |

|

Weighing bridge |

Mechanical component of the scale that carry the load. One or more load cells are integrated into the WeighingBridge as an element of mass determination. |

|

Weighing good id |

Defines the identifier of an Object that is to be weighed (load) |

|

Weighing instrument |

Synonym: scale |

|

Weighing module |

Part of the weighing instrument that comprises all mechanical and electronic devices (i.e. load receptor, load-transmitting device, load cell, and analog data processing device or digital data processing device) but not having the means to display the weighing result. It may optionally have devices for further processing (digital) data and operating the instrument. (OIML R76) |

|

Weighing range |

The range of a scale can measure a mass. A scale can have several weighing ranges with different scale divisions |

|

Width |

In third possible orthogonal direction to height and length |