The OPC 40084 series provides OPC UA information models for extrusion. The different parts describe the extrusion line as a whole, and the different components. This part provides general types that are used for extrusion. Together with OPC 40083, which defines general type definitions for the complete sector plastics and rubber machinery, it is the basis for all other parts.

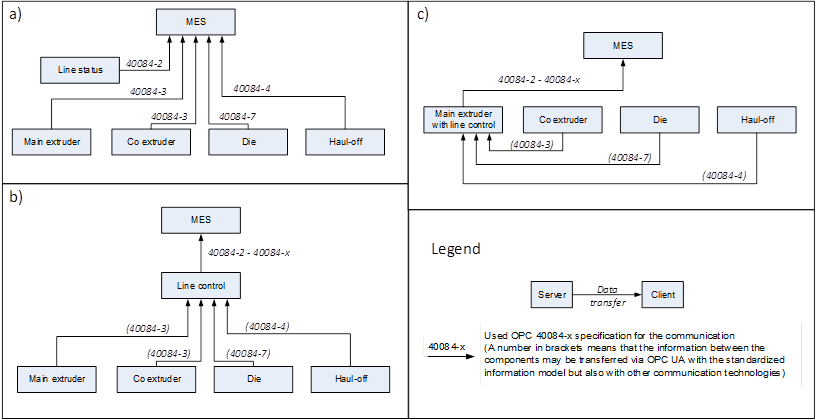

Different architectures are possible for the information flow between the components of an extrusion line and towards an MES. With the separated information models for the different components of an extrusion line three scenarios (and combinations of them) are possible:

- Each component has an own OPC server and is connected directly to an MES

- A line control collects all data from the components and forward these to the MES. The exchange between the line control and the components can be realised by OPC UA, but also by other technologies (e.g. field bus, EUROMAP 27)

- The line control is included in an extruder

Figure 1 – Different possibilities for the data flow

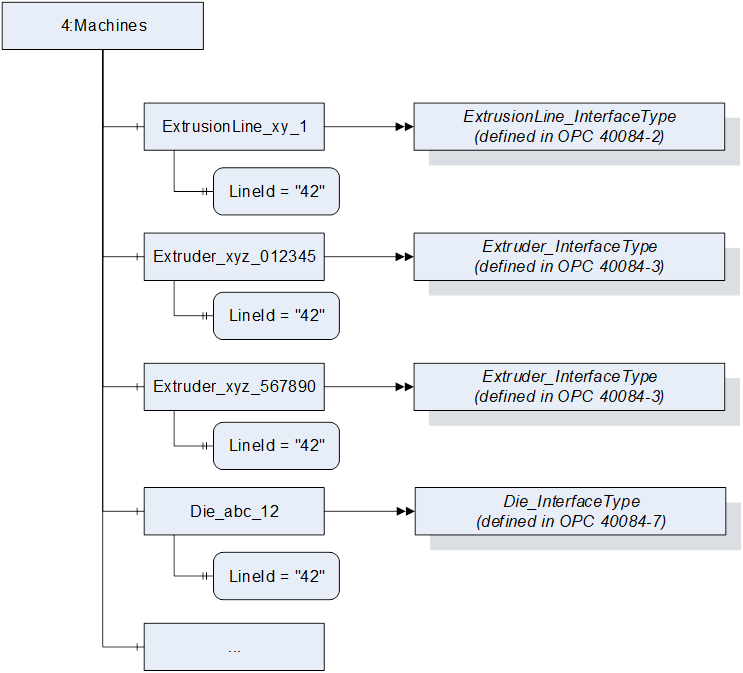

A server providing information for several components inside one extrusion line (here with the LineId “42”) would have the following structure (example):

Figure 2 – Example structure of a server representing several components of an extrusion line