The FeederType represents a device that transports material in an uncontrolled or controlled way. In the second case, the Feeder acts as a dosing unit. A feeder transports the material to a defined destination. This can be directly a barrel zone, but also another feeder which collects materials from several feeders above.

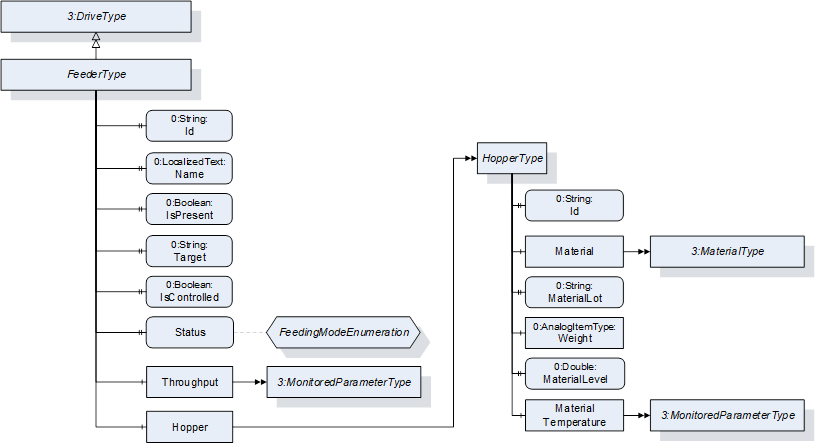

Figure 2 – FeederType Overview

Table 3 – FeederType Definition

|

Attribute |

Value |

||||

|

BrowseName |

FeederType |

||||

|

IsAbstract |

False |

||||

|

References |

Node Class |

BrowseName |

DataType |

TypeDefinition |

Other |

|

Subtype of 3:DriveType defined in OPC 40083 |

|||||

|

0:HasProperty |

Variable |

Id |

0:String |

0:PropertyType |

M, RO |

|

0:HasProperty |

Variable |

Name |

0:LocalizedText |

0:PropertyType |

M, RO |

|

0:HasProperty |

Variable |

IsPresent |

0:Boolean |

0:PropertyType |

M, RO |

|

0:HasProperty |

Variable |

Target |

0:String |

0:PropertyType |

M, RO |

|

0:HasProperty |

Variable |

IsControlled |

0:Boolean |

0:PropertyType |

O, RO |

|

0:HasProperty |

Variable |

Mode |

FeedingModeEnumeration |

0:PropertyType |

M, RO |

|

0:HasComponent |

Object |

Throughput |

|

3:MonitoredParameterType |

O, RO |

|

0:HasComponent |

Object |

Hopper |

|

HopperType |

O |

The Name Property gives the name of the feeder/dosing unit and is used as reference in the Target. Unique within the extruder

The Description Property gives a description of the feeder/dosing unit.

The IsPresent Property provides information if the feeder/dosing unit is physically installed and connected.

The IsActive Property provides information if the fedder/dosing unit is active in the current production.

The Target Property provides information to where the feeder brings the material. This can be a barrel zone (ExtrusionTemperatureZone) but also another feeder. The value of the Target Property shall be equal to the value of the Id Property of the relevant ExtrusionTemperatureZone or feeder.

NOTE: The Id Property is modelled inside the MeasuringDeviceType which is the basis for all zones.

The IsControlled Property provides information, if the feeder is controlled (by a valve, screw, …) or not (material just falls through by gravity).

The Mode Property provides information, how the throughput of the feeder is controlled.

Table 4 – FeedingModeEnumeration Definition

|

Name |

Value |

Description |

|

ONLY_CONVEYING |

0 |

The throughput is not controlled. The feeder only transports the material (e.g. by screw, conveyor belt) or the material is only falling through a feed opening |

|

OTHER |

1 |

Throughput is controlled, but in another mode than these below |

|

GRAVIMETRIC |

2 |

The throughput is controlled by a gravimetric dosing system. |

|

VOLUMETRIC |

3 |

The throughput is controlled by a volumetric dosing system. |

|

LIQUID |

4 |

The throughput of liquid material is controlled by a pump. |

|

BATCH |

5 |

The throughput is controlled by a batch dosing system. Note In this case, each material has an own feeder although there is only one physical system. |

Current throughput of the feeder/dosing unit in mass per time (e.g. kg/h). Although the modelling rule for this node is optional to cover also pure feeders, it is mandatory for dosing units. The MonitoredParameterType is defined in OPC 40083.