To establish communication between the higher-level controller and an IO device, the communication paths must be established. These are set up by the IO controller during system startup based on the configuration data received from the engineering system. This specifies the data exchange explicitly.

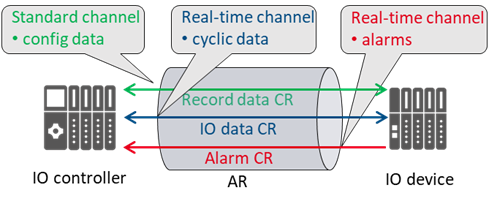

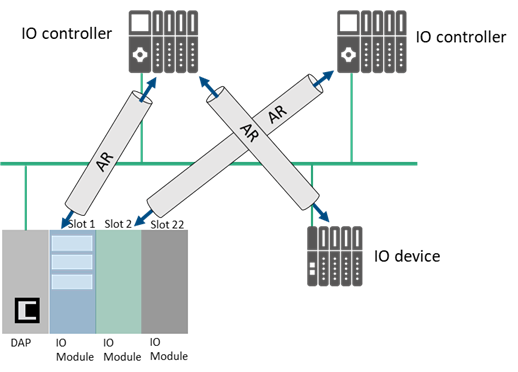

All data exchange is embedded into an AR (Application Relationship) (Figure 3). Within the AR, CRs (Communication Relationships) specify the data explicitly. As a result, all data for device modelling, including the general communication parameters, are downloaded to the IO device. An IO device can have multiple ARs established from different IO controllers, for example, for shared devices.

Figure 3 – Addressing of IO data in PROFINET based on slots and subslots

The communication channels for cyclic data exchange (IO data CR), acyclic data exchange (record data CR) and alarms (alarm CR) are set up simultaneously. Multiple IO controllers can be used in a PROFINET system (Figure 4). If these IO controllers can access the same data in the IO devices, this must be specified during parameter configuration (shared devices and shared inputs).

Figure 4 – Application and communication relationships

An IO controller can establish one AR each with multiple IO devices. Within an AR, several IO CRs on different APIs can be used for data exchange. This can be useful, for example, if more than one user profile (PROFIdrive, ENCODER etc.) is involved in communication and different submodules are required.