Most PROFINET Drives still support the PROFIdrive profile. PROFIdrive offers an interoperable interface for the access to standard parameters and vendor specific parameters. This offers the possibility for an edge device to use the PROFIdrive profile as a standardized interface for the access to drive data via PROFINET and PROFIBUS.

Nevertheless, the OPC UA information model of this specification is not limited to PROFIdrive devices, because the mandatory parts of the information model are independent from PROFIdrive and quite common to all drives, independent on their communication interface. Therefore, all drives with PROFINET interface and their own OPC UA Server on board can use the Information Model out of this specification. Additional benefit for drives with PROFIdrive (using PROFINET or PROFIBUS) is, that brownfield Devices can be represented by an OPC UA Server in an edge or proxy Device (like a PLC cell Controller) by using a generic mapping based on the PROFIdrive application model and using the PROFIdrive parameter channel as generic transport interface.

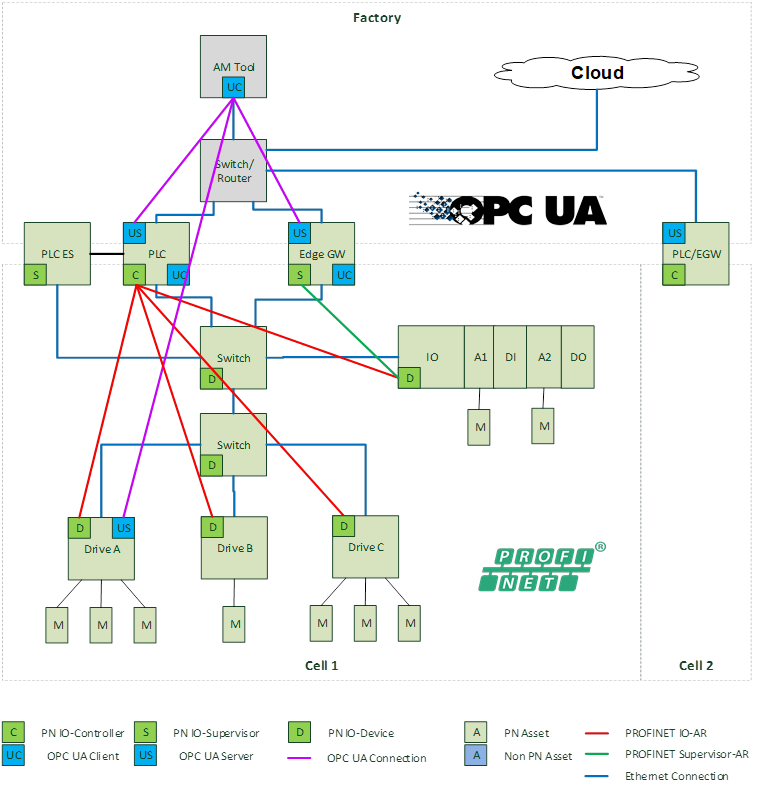

Figure 4 shows different possibilities for Vertical Communication and IT integration of PROFINET Drives in a typical automation scenario. Drive A in Figure 4 has it’s own OPC UA server on board. The onboard OPC UA Server of Drive A contains the standardized information model out of this companion specification and may contain in addition vendor specific extensions to the standardized Information Model as well as additional independent vendor specific Information Models. Because of PROFINET being real switched Ethernet, the PROFINET network in the OT areas is used to access the local OPC UA Servers in the OT area independent from the PROFNET communication.

Drives B, C and the Drive Axis modules in the IO-Station are brownfield Devices or cost sensitive Devices, offering only a PROFINET PROFIdrive interface without having an own OPC UA Server. For Vertical Communication and IT integration of these Drive Devices, they have to be proxied by an edge Device or the cell Controller PLC acting as proxy for the Information Model of the PROFINET Devices under its control. The proxy Devices use PROFINET communication and the PROFIdrive parameter channel to access data on the PROFIdrive Drive Devices in the OT level. With PROFIdrive Devices, the proxies can use a generic mapping of standardized PROFIdrive data into the standardized Information Model defined in this companion specification. In addition, also for these PROFINET only Devices, it is possible to extend the standardized Information Model by vendor specific extensions by using the PROFINET GSD Generic companion specification OPC UA part 30144 (see [OPC 30144 GSD]). With the GSD Generic approach, it is possible to advertise all information on additions to the OPC UA Information Model and related PROFINET data communication by additions to the standard PROFINET GSD. Therefore, the GSD Generic approach is easily applicable for brownfield Devices and plain PROFINET Devices.

Figure 4 – Overall Communication Scenario for PROFINET Drives