Part 2 offers an additional method of giving your service department information about what they should or should not try to disassemble on site during maintenance. It introduces the possibility to add a service class tag to the components, which gives information about what parts of the machine may be disassembled at the customer site and which components should only be removed as an assembly where you do not disassemble individual components.

So, let’s say you know that the system will be working in a dusty environment, possibly with oil mist in the air. Therefore, it is probably not a good idea to remove the lens from the image sensor at the production site as there is a high risk to render the image sensor useless because oil is deposited on it.

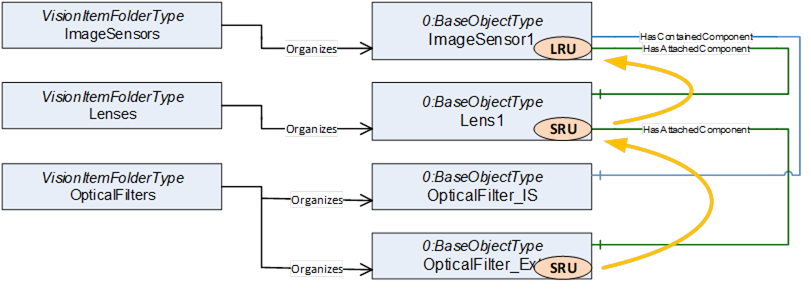

The service class standard originating from aircraft maintenance, but now used in a wide field of applications, defines some standard labels like “line replaceable unit” – this component may be removed at the customer site – and “shop replaceable unit” – this component should not be removed at a customer site; only at your workshop you are supposed to dismantle this assembly.

Figure 54 – Service Class Tags

By tagging the components you can give your service guys some information how to handle a repair. If the filter mounted on the lens gets damaged, you can browse the following information from the model:

the filter is tagged SRU – do not remove

the filter is attached to the lens, the lens is tagged SRU – do not remove

the lens is attached to the image sensor, that is tagged LRU – remove this assembly

Therefore, the service technician should remove the sensor together with the lens and filter mounted to it and take it back to the repair shop to replace the damaged filter.