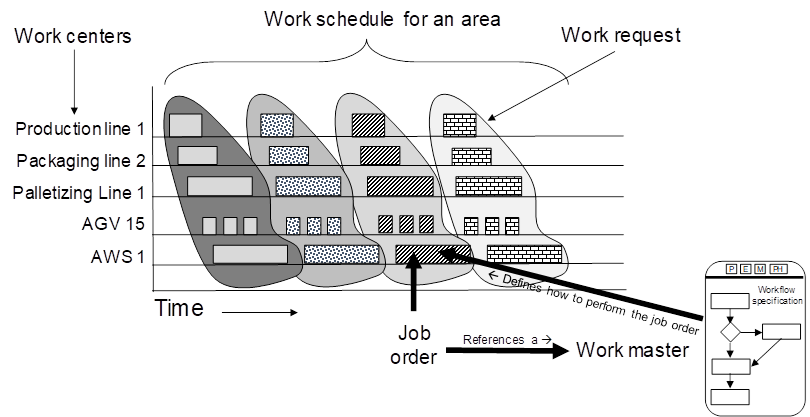

ISA 95 defines a Job Order as a request for a unit of work to be executed. Typically, these are the lowest level scheduled objects in a work schedule, as shown in Figure 1. In ISA 95 a Work Schedule defines all the activities to be accomplished to meet a production request (or production order). A Work Schedule is made up of one or more Work Requests, depending on how the work is to be split, such as one order for packaging of 1,000,000 bottles, to be executed as 4 separate work requests of 250,000 bottles each. Each Work Request is made up of one or more Job Orders which define the work to be done in a work center (such as a packaging line or production line).

Figure 1 – Work Schedule, Work Request, and Job Orders

Job Orders have a procedure or workflow that is followed, either automatically or manually. Typical Job Orders in serialization are packaging orders for specific products. The Job Order contains all the variable information about the order, such as quantity to be packaged, various values to be printed on labels, and any options, such as inserts to be added or case packing options. Each Job Order identifies a Work Master to be used. Work Master is the ISA 95 term for the procedure that is to be followed. Examples of Work Masters include ISA 88 Master Recipes or ISA 95 Workflow Procedures.

Job Orders are often sent from Level 3 MES/MOM systems to batch execution systems, automation systems (PLCs and DCSs), or workflow systems for manual operations. An often-used implementation is to have an ERP or MES sent Job Orders to specific parts of production. In Figure 1, for example a production line is executing one set of Job Orders, a packaging line is executing another set, synchronized with the production line, a palletizing line, synchronized with the packaging line, an AGV (Automated Guided Vehicle) system that executes a job to move materials from the palletizer to a AWS (Automated Warehouse System). Each of these systems perform independent job, with their own local Work Masters and workflows.

A Job Order contains values for job specific parameters (such as “Use By Dates” to be applied to labels), material requirements (such as an identification and quantity of the material lot to be produced), equipment requirements (such as which packaging line to use), personnel requirements for the job order (such as training requirements), and physical asset requirements (such as which testing equipment to use).