On the most abstract level, everything, except the atomic process, is just grouping operations together in different ways in many different layers when assembling a product. This requires a flexible model for different customer needs with respect to process control.

A combined process can be any of the following:

- A “Job” is a collection of sub-processes which could also include a sub-job.

- A “Batch Process” is a “Job” where all the operations are atomic and use the same joining program, and the operations are executed sequentially.

- Example: The process of sequential assembly of two or more joints using the same program.

- A “Synchronized Process (Sync)” is a “Job” where all the operations are executed in parallel by separate tools (spindles).

- Example: In a fixtured system which consists of multiple spindles, the PLC sends a synchronized process to the Joining Process Controller to manage which spindles should run. When the execution is completed, then a combined result is sent back to the PLC.

- A “Stitching Process” is a “Job” where several “Synchronized Processes” are done in a sequence.

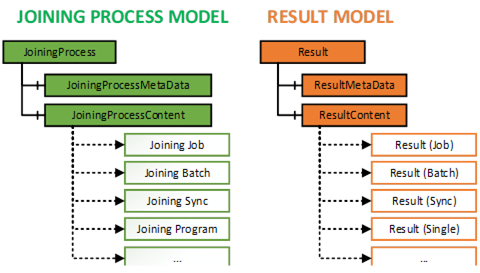

Joining Process and Result Mapping

The result is mapped to a corresponding joining process. Figure 22 describes the following examples.

- Examples:

- Result (Single) is mapped to a Joining Program.

- Result (Batch) is mapped to a Joining Batch.

- Result (Job) is mapped to a Joining Job.

Figure 22 – Joining Process and Result Model Mapping

Joining Process Use Cases

The following are a few cases that describe various types of jobs in a joining system.

Note: Quality Process and Vision Process are not defined in this specification. The purpose of the below examples is to describe the flexible usage of the joining process model and result model which covers various combinations of processes and corresponding outcomes from different domains.