For OPC UA users that may not be familiar with OPEN-SCS the following section provides a brief overview of key elements of serialization. See the OPEN-SCS Packaging Serialization Specification (PSS) 1.0 documentation for a full description of a serialization management system.

This document defines the serialization management OPC UA interfaces to support global regulation reporting requirements and the packaging serialization management process from the enterprise serialization manager to the packaging lines for serialized products.

Healthcare supply chain systems are being deployed to meet the product serialization and track-and-trace country regulations and laws to address the widespread healthcare counterfeiting issues. The regulations and laws require healthcare manufacturers to apply unique serialized identifiers to individual instances of physical objects for supply chain serialization and track-and-trace purposes.

Unique serialized identifiers may be generated within a company, may be obtained from regulatory authorities, or may be obtained by contract manufacturers from product owning company, depending on the regulations or laws that apply to the product and the intended market.

The key concepts of OPEN-SCS PSS are Serial Numbers, Serial Number Collections, Label Collections and Serialized Identifiers.

- A Serial Number is a string of characters with a defined syntax used for purposes of establishing uniqueness between otherwise identical objects.

- A Serial Number Collection is a collection of Serial Numbers which have not yet been printed onto a label. Serial Number Collections are defined to provide for efficient exchange of collections of Serial Numbers.

- A Label Collection is a collection of Serial Numbers with the same state and associated information needed for the label such as lot numbers, expiration dates and manufactured dates. Label Collections are defined to provide for efficient exchange of collections of Serial Numbers with the associated other information needed for the label.

- A Serialized Identifier is a unique identifier (serial number) comprising of a string of characters within a defined format that is associated with a physical object such that no two physical objects are associated with the same string of characters. Abbreviated as SID. An example of an SID is an Electronic Product Code (EPC) that is a unique identifier attached to a class of product or aggregation such a pallet, with the addition of a unique serial number for each product or aggregation.

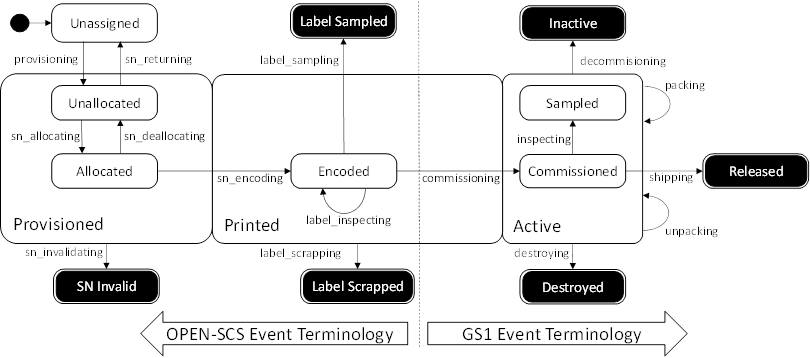

The general lifecycle of a Serial Number is from unassigned, to associated with a production run, to representation on printed label, to a commissioned label, as shown in Figure 1. When the serial number is printed it is combined with other information required on the label, for example: product code, lot number, expiration date, etc. Figure 1 illustrates the stages of Serial Numbers:

- An unassigned Serial Number, where the number has not been assigned to any specific product, production order, or packaging run.

- A provisioned Serial Number containing the serial number in a digital form that has been associated to a specific product, package type, production order, or packaging run.

- The Serial Number as it is printed on a label and combined with other label information, but not yet applied to the physical product, called a printed label.

- The printed label as it is applied to the physical product, called a commissioned label, and identified as a Serialized Identifier (SID).

Figure 1 – Lifecycle Stages of a Serial Number

In some cases, the activity of serialization includes the packing of serialized child objects (packages) into serialized and parent objects (containers) in a process identified as aggregation. Serialization aggregation events usually start with the Lowest Saleable Unit (LSU) (e.g. bottle or blister pack) and potentially include multiple levels in the packaging hierarchy (such as a pallet made up of cases, cases made up of packages, and packages made up of blister packs, with serialization information defined at each level of the hierarchy.) Aggregation Serial Numbers follow the same lifecycle as product Serial Numbers.

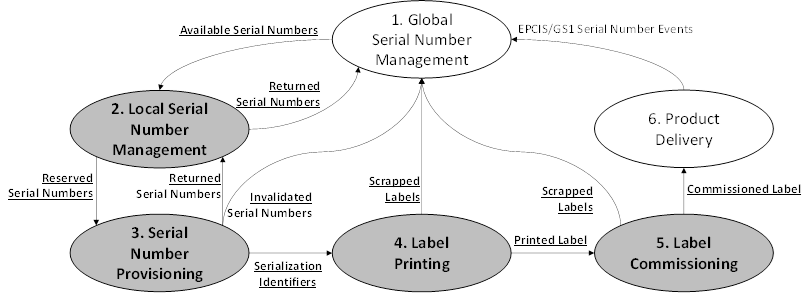

The activities of serialization are illustrated in Figure 2. Each of the activities may be performed for each level of a packaging aggregation hierarchy, such as separate serial number management, provisioning, printing, and commissioning for pallet labels, and similar activities for cases and cartons. The scope of the OPC UA OPEN-SCS implementation are information exchanges between the activities. Not all communication exchanges are shown in Figure 2.

Figure 2 – Activities in Serialization

- Global Serial Number Management – This is the activity of creating, allocating, registering, and general management of Serial Numbers. This activity may be local (within a company) or remote in a regulatory agency or a third party. Generally, this activity is global in scope, even within a company, in order to ensure that uniqueness of Serial Numbers. Global serial number management may deal with any Serial Number state, but generally deal with unassigned, invalid, scrapped, destroyed, commissioned, sampled, or inactive states.

- Local Serial Number Management – This is the activity of managing available Serial Numbers, assigning Serial Numbers to production of specific products, packages, or aggregations. Generally, this is local in scope (within a company, a site within the company, or area within the site) in order to meet performance requirements in obtaining Serial Numbers for provisioning. If locally managed Serial Numbers which have not been commissioned and will not be used, they are generally returned to global serial number management for possible reuse.

- Serial Number Provisioning – This is the activity of associating a Serial Numbers with a specific production run. This activity is generally performed locally (within a company, a site within the company, or area within the site), but may be done by a third party that is pre-printing labels. This activity may be done some time before the label is printed, because of limitations in the printing system, or just-in-time if available on the printing system. If Serial Numbers cannot be used (such as more are provisioned than are needed for the production run), then the unused numbers are either returned to local or global serial management for possible reuse or reported as invalid for tracking purposes.

- Label Printing – This is the activity of printing the Serial Numbers and related information on a label. This is usually in the form of a 1D barcode, QR (2D), DataMatrix or RFID tag. If the printed labels are scrapped before they are commissioned, then the Serial Numbers associated with the labels are usually returned to local or global serial number management indicating that labels with the serial numbers were printed, but the labels were scrapped.

- Label Commissioning – This is the activity of associating a label with a product or package. Typically this involves attachment of the label to the product or package. If the association is later removed and the label scrapped, such as the label being removed from the product/package because of rework of the product, then the Serial Numbers on the scrapped label are reported to local or global serial number management for tracking. Once the Serial Number is associated with a product, package, or aggregation it is known as a SID.

- Product Delivery – This is the activity of shipping the product/package out of the custody of production to other parts of the business or the supply chain. If the product is destroyed or otherwise made non-usable, then the destroyed Serial Numbers are usually returned to global serial number management for tracking. Often the transfer of custody is to local warehouses or shipping departments.

Each of the activities may be performed for each level of a packaging aggregation hierarchy, such as separate serial number management, provisioning, printing, and commissioning for pallet labels, and similar activities for cases and cartons.

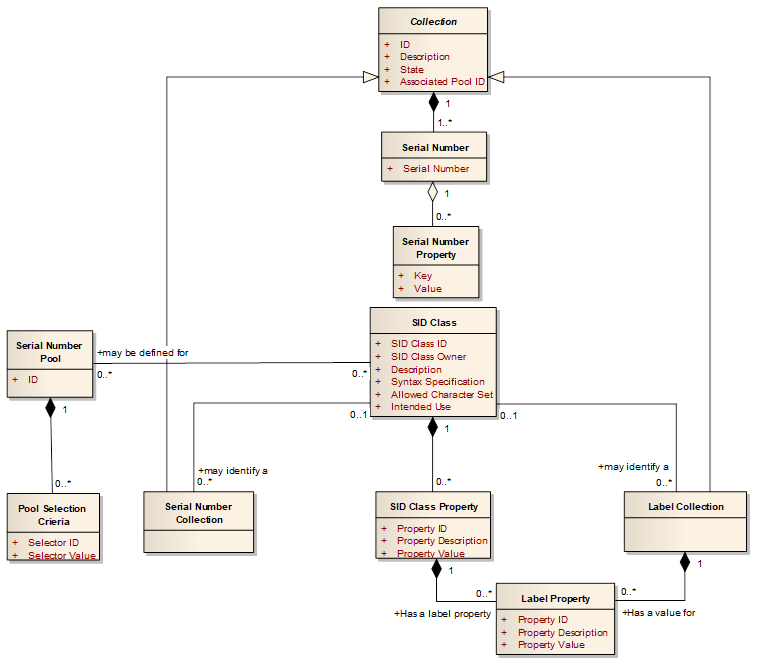

The information objects identified in Figure 3 are used to describe the information used in the serialization services.

- SID Class - An SID Class represents information specified by global industry standards, governmental standards or regulation used in representation of a Serial Number in an SID. Each standard or regulation defines one or more SID Classes including the specification of the syntax of the SID and the allowed character set, the internal structure and the intended area of use.

- SID Class Property - Additional information associated with the SID Class is represented in name/value pairs and defined SID Class Properties.

- Collection – An abstract class that is a representation of a list of Serial Numbers is defined as a Collection.

- Serial Number Collection - A representation of a list of numbers from which Serial Numbers may be obtained is defined as a Serial Number Collection.

- Serial Number - A string of characters with a defined syntax used for purposes of identification to be used for serialization purposes is defined as a Serial Number.

- Label Collection - A set of Serial Numbers which have been, or will be encoded onto a label, with all the same state and associated to a specific production or packaging run is defined as a Label Collection.

- Label Property – Additional information associated with a label for a SID Class Property is defined as a Label Property.

- Serial Number Pool - A representation of a managed collection of Serial Numbers which may be associated with multiple SID Classes, and which have selection criteria defined to allow selection of sets of numbers for specific purposes is defined as a Serial Number Pool.

- Pool Selection Criteria - A set of key/value pairs which represent selection criteria that may be used to determine what set of Serial Numbers are returned from a serial number request service is defined as a Pool Selection Criteria.

Figure 3 – Serialization Information Model

Note:The model above is different from the Version 1 PSS model, through the addition of a set of optional Serial Number Properties for each Serial Number. This was added to handle the case, such as in Russia, where there is optional additional information associated with each Serial Number which is exchanged information. See Section 6.4.2.

The state and event model for a Serial Number shall follow the model displayed in Figure 4.

Note 1The state is managed is a distributed manner, no single system provides the state of the serial numbers. The events and methods defined in this document provide the means for applications to manage their internal state representation.

Note 2All Serial Numbers in a Serial Number Collection only contain Serial Numbers with the same state.

Note 3All Serial Numbers in a Label Collection only contain Serial Numbers with the same state and ancillary information.

Note 4Generally the events that record a transition can come from any state or substate.

Figure 4 – Serial Number State and Event Model

Each Serial Number state is defined in Table 1.

Table 1 – Serial Number State Definitions

|

SID State |

Description |

Examples |

|

Unassigned |

The Serial Number has not been assigned to production or a packaging run. The unassigned state is used for communication to systems that assign serial numbers. |

A request is sent to an agent or serial number management system that creates serial numbers, along with possible information such as product codes. |

|

Unallocated |

As Serial Number has been assigned to production or a packaging run, but it has not yet been allocated for use a specific production run of a product or aggregation. |

A local serial number management system maintains a set of unallocated serial numbers. |

|

Allocated |

The Serial Number has been assigned to a specific product or aggregation production run. |

Serial Numbers are available and maintained in a local printer for printing on a label. |

|

SN Invalid |

The Serial Number is no longer viable, and the related serial number is no longer defined. The Serial Number will not be the subject of subsequent events. |

A process order using the Serial Numbers was cancelled, the provisioned Serial Number are not associated with a physical product and will not be further used. |

|

Encoded |

The Serial Number has been written to a barcode or RFID tag, but not yet commissioned. |

An industrial printer prints a label. |

|

Label Sampled |

The printed label has been retained and is not associated with a physical product or aggregation. |

A printed label is attached to a batch record. |

|

Label Scrapped |

A label was encoded with a Serial Number but was made unusable before being applied to a product or aggregation. |

A vision system detects that a label was misapplied or ripped on a product or aggregation and the label was removed from the product or aggregation. |

|

Commissioned |

The Serial Number has been associated with a physical product or aggregation but has not yet left the responsibility of production. The Serial Number can now be identified as a SID. |

A label is attached to a package, and the package is being placed into a case, and the case is being placed on a pallet. |

|

Sampled |

The product or aggregation is to be used as a sample for testing or other use, not to be made active. |

Product was pulled from the end of the packaging line and stored in a facility for later stability testing. |

|

Inactive |

The product or aggregation is no longer active but may not have been destroyed. GS1 defines this disposition as a decommissioned object that may be reintroduced to the supply chain, however any status change after decommissioning is not in scope of the PSS. |

Product over its expiration date is send to a facility for destruction or for testing to determine its viability. |

|

Destroyed |

The product or aggregation has been fully rendered non-usable. |

A production error was detected, and all packaged product was pulled from the line and destroyed. |

|

Released |

The Serial Number has been associated with a physical product or aggregation and has left the responsibility of production. |

A pallet of products/packages is delivered to the warehouse and the transfer of control is sent to the ERP system. |

Each Serial Number event is defined in Table 2. The events occur as a result of a business or process step.

Table 2 – Serial Number Events

|

Event |

Description |

|

provisioning |

Unassigned Serial Numbers were made available for use in eventual encoding and commissioning. |

|

sn_returning |

Unallocated Serial Numbers may be returned to the Unassigned state |

|

sn_allocating |

Unallocated Serial Numbers are to be assigned for use in a packaging run |

|

sn_deallocating |

Unused allocated Serial Numbers may be returned to the unallocated state. |

|

sn_invalidating |

Provisioned Serial Numbers are no longer available for use |

|

sn_encoding |

Serial Numbers and other associated information are written to a barcode or RFID tag but are not yet associated with a product or aggregation. (Derived from the GS1 “encoding” business step.) |

|

label_inspecting |

Written barcode or RFID was read to address potential physical or documentation defects. |

|

label_sampling |

Written barcode or RFID is pulled from production and retained as a sample for later testing or inspection. |

|

label_scrapping |

Written barcode or RFID was made unusable in production and the serial number if no longer associated with a packaging run |

|

commissioning |

A Serial Numbers is associated with a specific product or aggregation. (Derived from the GS1 “commissioning” business step.) |

|

inspecting |

Product or aggregation is pulled from production and retained as a sample for later testing or inspection. |

|

shipping |

Indicates the overall process of staging, outbound, loading and departing the responsibility of production. (Derived from the GS1 “shipping” business step.) |

|

decommissioning |

Process of disassociating an instance-level identifier (Serial Number) with an object. For example, either time or an event has caused to the serial number to be disassociated with a product or aggregation. (Derived from the GS1 “decommissioning” business step.) |

|

destroying |

Process of terminating a physical object. For an instance-level identifier, the object will not be the subject of subsequent events; subsequent events are likely indicative of error (such as a stray read of a tag inside an incinerator). (Derived from the GS1 “destroying” business step.) |

|

packing |

Denotes a specific activity within a business process that includes putting objects into a larger container. For example, adding labeled bottles into a case or adding cases into a pallet. (Derived from the GS1 “packing” business step.) |

|

unpacking |

Denotes a specific activity within a business process that includes removing products (individuals, inners, cases, pallets) from a larger container. For example, removing labeled bottles from a case or removing cases from a pallet. (Derived from the GS1 “unpacking” business step.) |

The OPEN-SCS PSS defines a technology independent set of functions that are to be provided to support serialization, and information on Serial Number Pools and SID Classes.

The following table defines the functions identified in the OPEN-SCS PSS, the method defined by this specification, and definition of the method’s use:

Table 3 – OPEN-SCS PSS Function to OPC UA Method Mapping

|

OPEN-SCS PSS Function |

OPC UA Method |

Method Use |

|

Serial Number Request Unassigned |

SNRequestUnassigned |

Pull of information from a pool management server |

|

Serial Number Request Unallocated |

SNRequestUnallocated |

Pull of information from a pool management server |

|

Serial Number Request Allocated |

SNRequestAllocated |

Pull of information from a pool management server |

|

Serial Number Return Unallocated |

SNReturnUnallocated |

Push of information to a pool management server |

|

Serial Number Return Allocated |

SNReturnAllocated |

Push of information to a pool management server |

|

Serial Number To Unallocated |

SNtoUnallocated |

Push of information to a pool management server |

|

Serial Number To Allocated |

SNtoAllocated |

Push of information to a pool management server |

|

Serial Number to Encoded |

SNtoEncoded |

Push of information to a pool management server |

|

Serial Number Invalidating Event |

SNInvalidatingEvent |

Push of information to an event management server |

|

Label Encoding Event |

LabelsEncodingEvent |

Push of Information to an event management server |

|

Label Scrapping Event |

LabelsScrappingEvent |

Push of information to an event management server |

|

Label Inspecting Event |

LabelsInspectingEvent |

Push of information to an event management server |

|

Label Sampling Event |

LabelsSamplingEvent |

Push of information to an event management server |

|

SID Commissioning Event |

SIDCommissioningEvent |

Push of information to an event management server |

|

SID Destroying Event |

SIDDestroyingEvent |

Push of information to an event management server |

|

SID Shipping Event |

SIDShippingEvent |

Push of information to an event management server |

|

SID Inspecting Event |

SIDInspectingEvent |

Push of information to an event management server |

|

SID Decommissioning Event |

SIDDecommissioningEvent |

Push of information to an event management server |

|

Aggregation Packing Event |

AggregationPackingEvent |

Push of information to an aggregation management server |

|

Aggregation Unpacking Event |

AggregationUnpackingEvent |

Push of information to an aggregation management server |