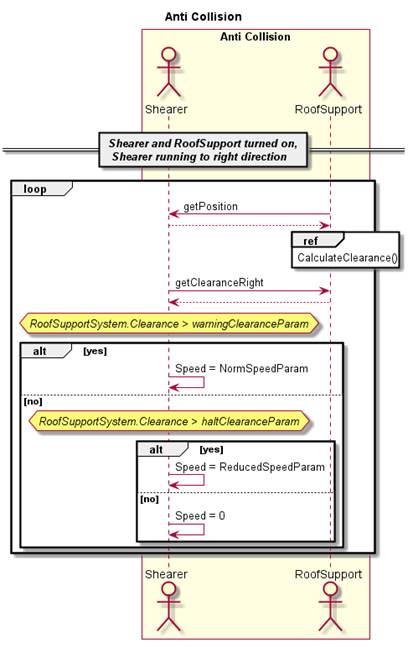

The Anti-Collision UC describes the automated process of preventing collisions between the Shearer cutting drums and the Roof Support Shields. The Shearer receives information about the clear area and is responsible for decreasing speed or stopping before a collision would occur.

The Roof Support System cyclically reads the Shearer’s position. By taking the Shearer’s position, dimensions and the actual position of the shields into account, the Roof Support System calculates clearance values for each side of the machine (ClearanceLeft and ClearanceRight). These values reflect the area, in which it is safe for the shearer to move. The values are based on the Shearer’s center of machine.

Depending on the current project/mine, the clearance values will be determined in different ways and will include different factors. Depending on the application, the Roof Support System can check sensor values of flipper, forepole canopy, setting pressure and advance ram.

The Shearer cyclically reads the clearance value for the current movement direction (ClearanceLeft or ClearanceRight) and reduces its maximum speed, if the clearance is below a warning threshold, or even stops, if it is lower than a halt threshold.

For advanced operation, the Roof Support System’s clearance can be used for a linear increase of the Shearer’s maximum speed. Figure 6 displays the sequence diagram of this UC.